Biomedical Engineering Reference

In-Depth Information

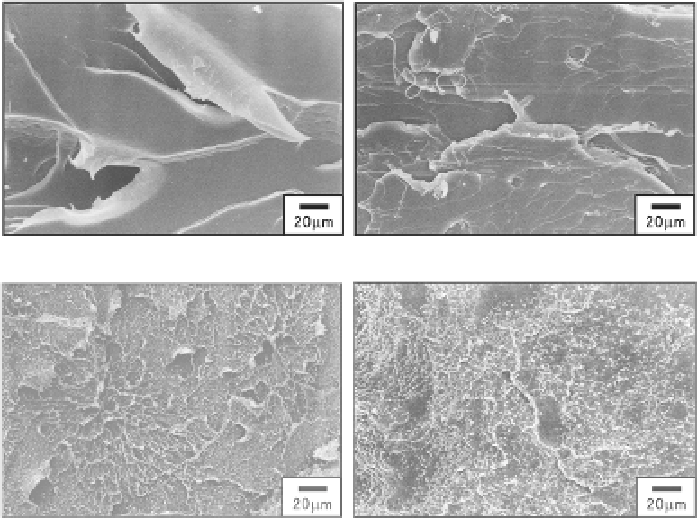

(a)

X

c

=2.7%, static (b)

X

c

=2.7%, impact

(c)

X

c

=55.8%, static (d)

X

c

=55.8%, impact

Fig. 4. FE-SEM micrographs of fracture surfaces.

2.2 Effect of unidirectional drawing process

Drawing process is known to be an effective way to improve the mechanical properties of

thermoplastics, and effects of drawing on tensile and fracture properties of thermoplastics

such as polypropylene (Mohanraj et al., 2003a, 2003b; Uehara et al., 1996), poly(acrylonitrile)

(Sawai et al., 1999; Yamane et al., 1997) and PLA (Todo, 2007) have been studied. PLA is

usually draw-processed when it is used for bone fixation devices, and therefore,

fundamental effect of drawing on its fracture behavior needs to be characterized. As an

example, dependence of draw ratio on the critical

J

-integral at crack initiation,

J

in

, is shown

in Fig.5. In the fracture specimens, the initial notches were introduced in the direction

perpendicular or parallel to the drawing direction. Therefore, the two different types of

specimens are denoted as 'perpendicular' and 'parallel'. For the parallel,

J

in

decreased with

increase of draw ratio, and

J

in

for draw ratio of 2.5 became about one fifth of the original. On

the contrary, for the perpendicular,

J

in

increased as draw ratio increased, and

J

in

for draw

ratio of 2.5 became five times greater than that of the original. Thus, greater energy is

needed for crack propagation in the perpendicular than in the parallel. This is easily

understood by considering the effect of drawing on the micromechanism of fracture. In

draw-processed polymer, molecules are reoriented in the drawing direction. Therefore,

energy dissipation during crack growth by elongation and scission of such oriented

molecules is much greater in the perpendicular direction than in the parallel direction where

such elongation and scission processes obviously decrease.

FE-SEM micrographs of fracture surfaces are shown in Fig. 6. The perpendicular with draw

ratio 2.5 exhibited rougher surface with ductile deformation than the original (without

drawing). It is interesting to note that crevices existed on the fracture surfaces that were

thought to be cracks transversely propagated between the parallel fibrils reoriented in the