Environmental Engineering Reference

In-Depth Information

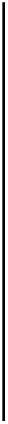

Table 7.7 Typical formulation of liquid explosives containing nitromethane and metal powder

Raw material

Formulation

1

2

3

4

5

Nitromethane

66

69

68

61

60

Nitroglycerine

10

RDX

9

7

HMX

7

Potassium nitrate 20

Sodium nitrate 22

Aluminum powder

12

11

12

PETN

10

Magnesium powder

11

1.2

Cellulose acetate

1

Diethylene glycol dinitrate

9.5

2

4

Nitrocellulose

1

1

2

Resorcinol

1

1.5

White yin

1

Cav-o-sil

1

1

2

3

2

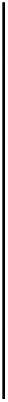

Table 7.8 Properties of liquid explosives described in Table

7.7

Properties

1

2

3

4

5

Charge density

(g/cm

3

)

1.416

1.363

1.379

1.472

1.521

Minimum criti-

cal detonating

diameter (inch)

1/64

1/32

1/32

1/2

1/2

Detonation

velocity (m/s)

6,230

7,140

6,190

5,120

5,200

Explosion rate

initiated by

5,000 g ham-

mer (%)

0

8

8

12

0

8

0

8

0

8

-

-

-

-

-

Charge mode

and detonation

mode

Filling,

directly initi-

ated by no. 8

detonator

Filling,

directly initi-

ated by no. 8

detonator

Filling,

directly initi-

ated by no. 8

detonator

Filling,

with

booster

pellet

Filling,

with

booster

pellet

Storage time

(year)

10

8

5

3

3

explosives is only 0.4 mm or so, thus they are not only useful for military purposes

but also can be employed as explosives for oil wells (Table

7.8

).

(2) Adding sensitizers to nitromethane to prepare thermobaric explosives

Adding certain amounts of fuels such as RDX and aluminum

fl

flakes into

nitromethane can signi

cantly improve the detonation outcome. Chunhua Bai in

Beijing Institute of Technology [

37

] developed a liquid-solid type slurry explosive

by mixing nitromethane with metal powder, which was found to possess excellent

detonation properties. The formulation of this explosive was shown in Table

7.9

.