Civil Engineering Reference

In-Depth Information

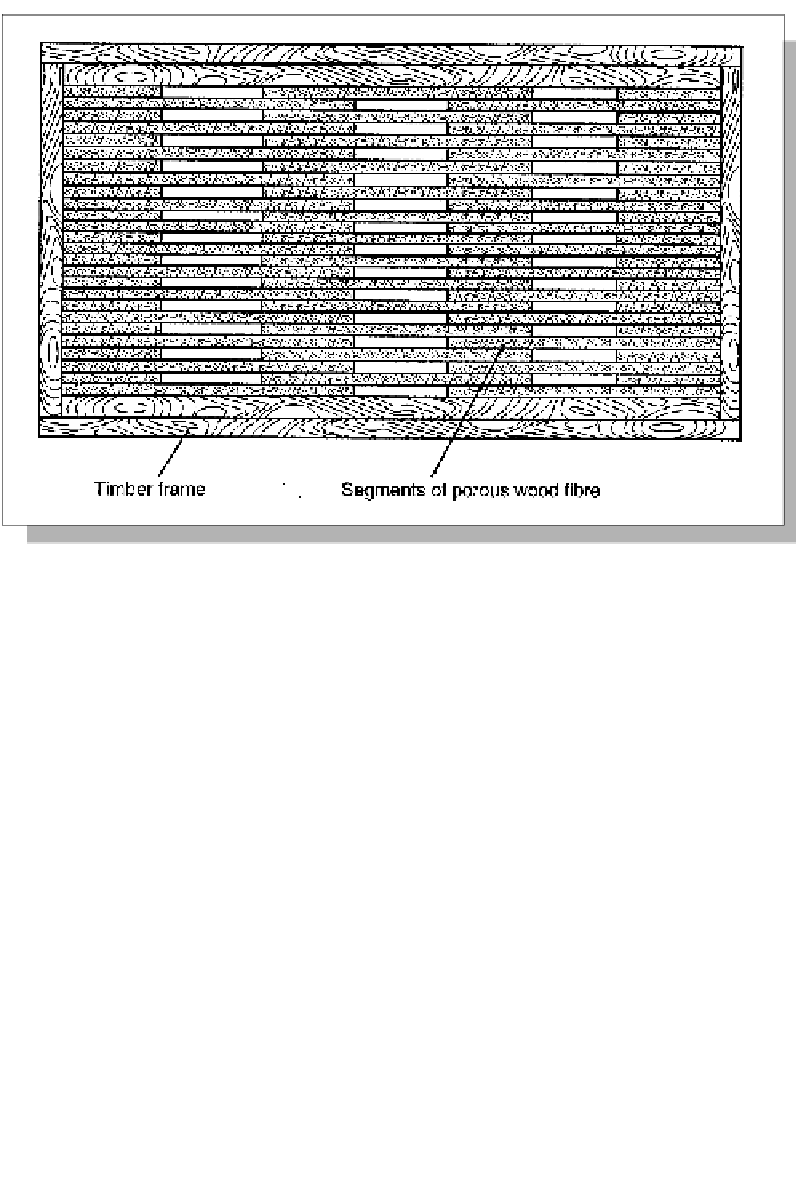

Figure 16.5: Section through a sound-insulated door.

Flush doors also have a frame, but not as large as the frame of a panelled door.

A flush door is stiffened by thin layers of board, fibreboard or plywood, fixed

with adhesive or pins on both sides. External doors must use a water-insoluble

adhesive. Thermal insulation can be placed in the space between the layers of

fibreboard, e.g. expanded polystyrene, mineral wool and porous fibreboard,

woodwool slabs, wood shavings, etc. For light doors it is usual to add a sound-

insulating layer of corrugated cardboard or layers of interlocking wood fibre

bands, a waste product from the wood fibre industry. In fire doors non-flamma-

ble sheets of plasterboard or other heavy materials are inserted. A flush door can

also have glazing, but glazing will need its own frame.

The normal adhesives used in door manufacture are resorcinol, phenol,

polyvinyl acetate (PVAC) and polyurethane. Casein glue, animal glue and soya

glue can also be used. Doors are often delivered ready to hang, so they have

either a polyurethane varnish or an alkyd or linseed oil painted finish.

The environmental aspects of timber doors are good, but it is quite clear that

the choice of insulating material, glued boards, sealing strips, surface treatment

and ironmongery all play their part in production consequences and have effects

on the internal environment.

Doors can often be re-used, especially robust, solid panel doors. It is also an

advantage if the door frame can be dismantled with the door. The manufacture