Civil Engineering Reference

In-Depth Information

handle is heavy hardwood and the

rammer is made of iron. The

weight of a rammer should be

around 6-7 kg.

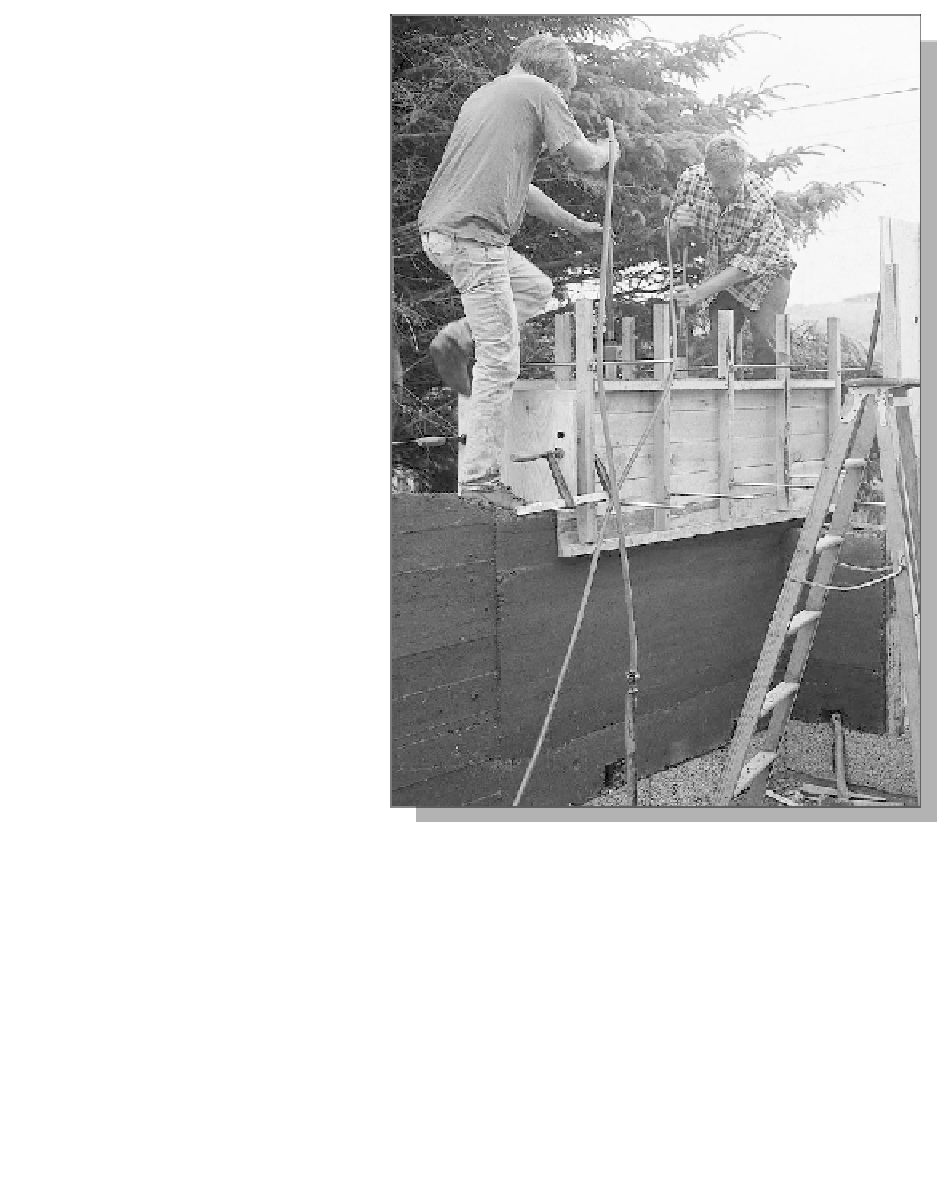

Ramming by machine is much

more effective. This can be done

using a compressed air hammer with

a square steel head of 12

12 cm.

The compressor's power should be

around 5 hp per hammer. The job

must be done by an operator who

can steer the machine; it is heavy

work. A robot-rammer which can fol-

low the line of the shuttering is being

developed in Germany.

Ramming is best carried out by a

working team of two or three peo-

ple. The wall shuttering is mounted

on the foundation walls as in Figure

13.22 with gable ends and separat-

ing boards.

When ramming by machine layers

of 13-14 cm can be built. This is

approximately two thirds of the vol-

ume of the original loose earth.

When ramming by hand a layer

thickness of not more than 8 cm is

advisable. Clearly the two methods

cannot be used together. It is impor-

tant to ram at the edge of the shut-

tering when machine ramming -

starting in the middle may cause

stones and lumps to be pushed out

to the edge and loosened. The ramming should make the earth as hard as rock - it

should 'sing out' - and a pick should not make any marks when the surface is hit.

When the first layer is ready, the next layer is begin, and so on until the shut-

tering is full. The rods are then pulled out and moved up the shuttering. With

each move it is necessary to check that the shuttering is vertical. The conical post

on the gable end of the shuttering acts as a 'locking key' to increase the stability

of the wall.

In the corners reinforcement of twigs or barbed wire are used, and after the

first layer, holes are cut for the floor beams, which will be placed directly on the

Figure 13.20: Ramming earth with a compressed air machine.

Source: Gaia Lista 1991