Civil Engineering Reference

In-Depth Information

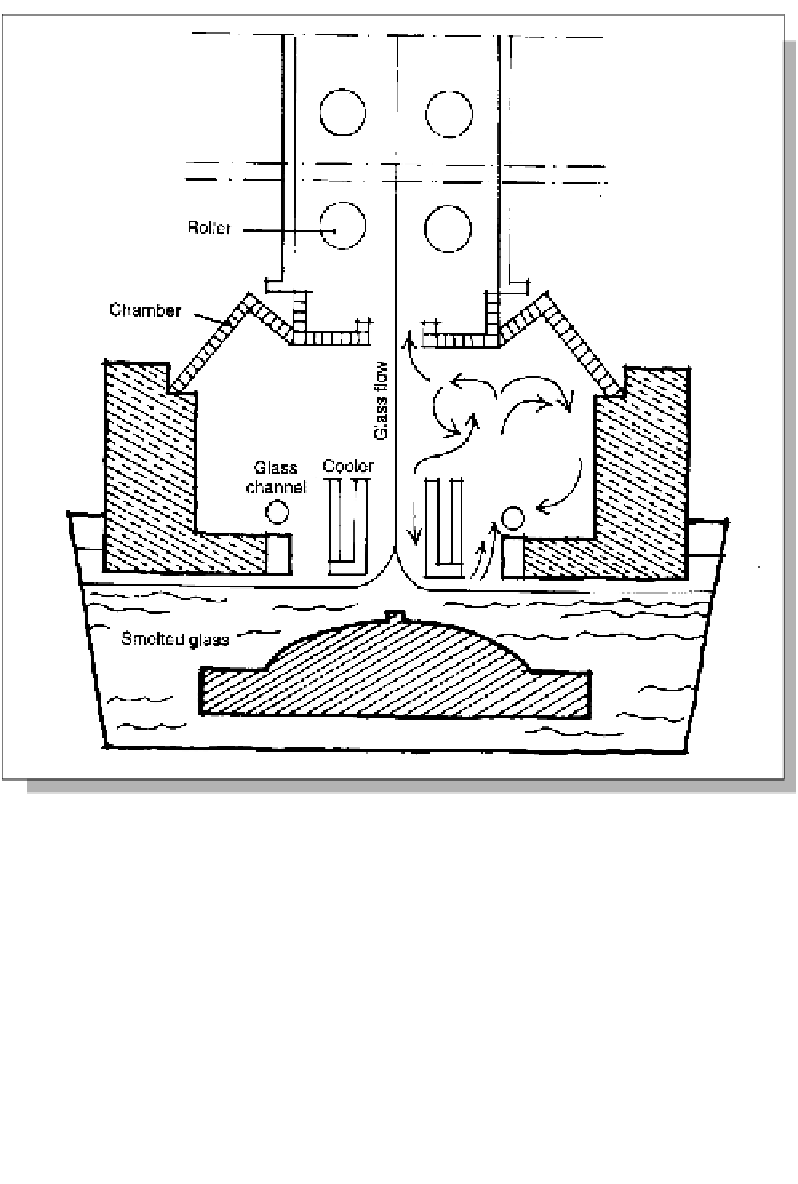

Figure 6.7: The principles of the production of machine glass. Source: Saten 1980

Machine glass

Figure 6.7 shows the production process for machine glass. The glass mass is

cooled to 950°C to become a little tougher. It is then drawn through a flat nozzle

out of the kiln and vertically up between a set of asbestos rolls in a cooling shaft

about 12 m long. At the end of the shaft the glass is cut into the required lengths

and slowly cooled.

Float glass

Instead of pulling up the glass substance vertically it is poured out over a bath of

floating tin. This produces a totally flat sheet which it is cut and cooled. This is

the method used by most glass manufacturers today.