Civil Engineering Reference

In-Depth Information

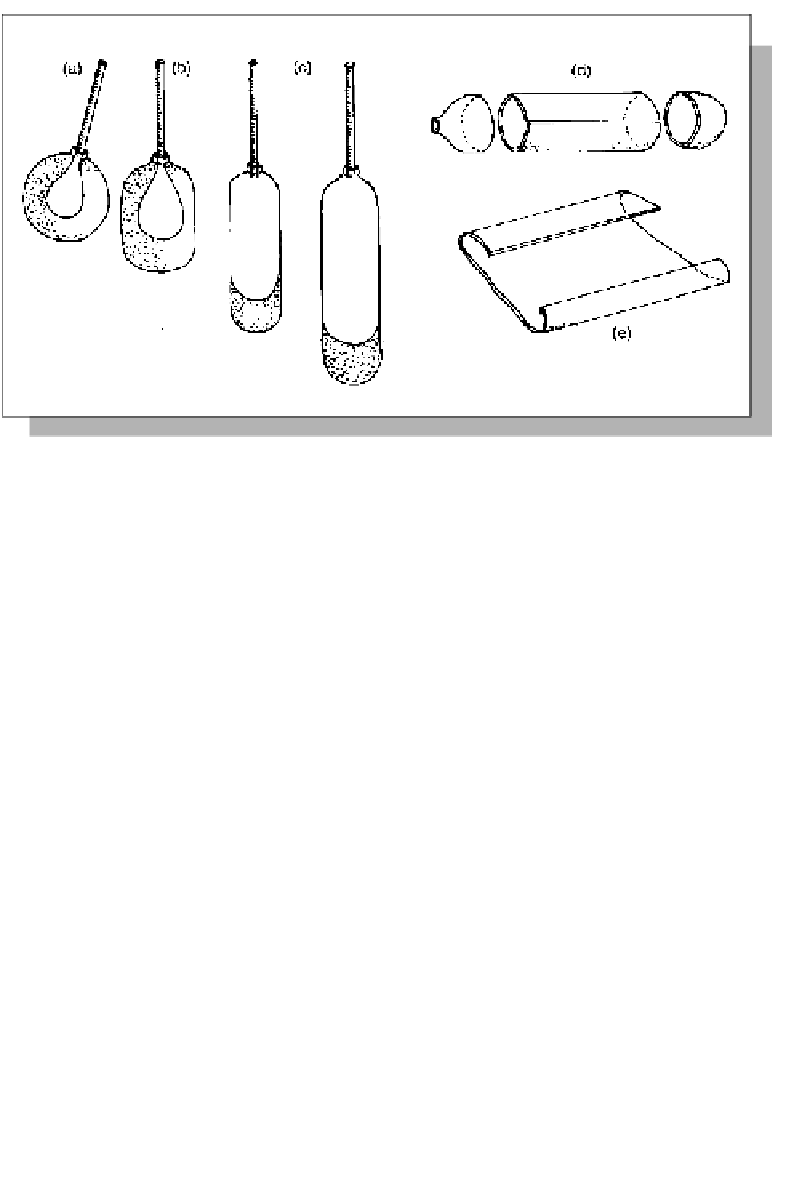

Figure 6.6: The production of table glass: (a)-(c) the glass is blown within a mould into a

cylinder; (d) the end pieces are cut off; (e) the cylinder is opened up and divided into the

required sizes.

Casting

Casting, most likely the first method for glass plate production, works on the

simple principle that the smelted glass mass is poured into smooth moulds and

then rolled out. This technique is still used for some types of glass where translu-

cency is less important, e.g. decorative glass, profiled glass and wired glass.

Glass bricks are made from two cast half blocks stuck together.

Crown glass

Crown glass was the most usual method up to about 1840. Figure 6.5 shows the pro-

duction process. The glass is blown up to a bubble, a pin is stuck to the sphere, and

the blowpipe removed. The pin is spun while the glass is warmed and the glass

bubble opens up, becoming a circular disc up to 1 m in diameter, which can then be

cut into panes. The pane in the middle - the bottle glass - is the lowest grade. Crown

glass has low optical quality, with bubbles, stripes and uneven thickness. Today it

is only used as decoration, or in panes where translucency is not required.

Table glass

Figure 6.6 shows the production process for table glass. The glass mass is blown

into an evenly thick cylinder in a mould 2-2.5 m long and 60 cm in diameter cast

in the floor. After blowing, the end pieces are removed and the cylinder is opened

along the middle. The glass is then warmed and stretched into a large flat sheet.

Table glass has a much better optical quality than crown glass. With this method,

larger panes of glass can be produced.