Environmental Engineering Reference

In-Depth Information

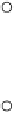

The energy-saving ratios of the other furnace groups increased virtually in

proportion to the respective processing temperatures (

Figure 5.86

)

.

Rate of Change of Unit Energy Consumption before and after the Modifica-

tions:

U

U

am

η =−

1

bm

where

η

= energy saving ratio

U

am

= unit fuel consumption after modification

U

bm

= unit fuel consumption before modification

Because continuous heating furnaces consume a large amount of fuel, the amount

of energy saved was substantial, although the energy saving ratio appeared to be

low numerically. On the contrary, the amount of energy saved in batch-type heat

treatment furnaces was small as both the size of each facility and fuel consumption

were generally small (

Figure 5.87

)

, i.e.,

∆

E

= η

E

bm

where

∆

E

= amount of energy saved

E

bm

= energy consumption before modification

100.0

80.0

60.0

40.0

20.0

0.0

0

200

400

600

800

1000

1200

1400

1600

Atmospheric Temperature in Furnace,

°

C

Continuous heating furnace

Continuous heat treatment furnace

Melting furnace

Batch type heating furnace

Batch type heat treatment furnace

Ladle

Gas treatment furnace

FIGURE 5.86

Relation between atmospheric temperature in furnace and energy-saving ratio.

Search WWH ::

Custom Search