Environmental Engineering Reference

In-Depth Information

where

V

A

m

3

= total airflow (

/h)

m

3

V

E

= total exhaust gas flow (

/h)

T

Ai

= inlet air temperature (

˚

C)

T

Ei

= inlet exhaust gas temperature (

˚

C)

T

Ao

= preheating (outlet) air temperature (

˚

C)

C

PAo

= specific heat of preheating air (kJ/m

3

K)

C

PAi

= specific heat of inlet air (kJ/m

3

K)

C

PEi

= specific heat of inlet exhaust gas (kJ/m

3

K)

C

PEa

= specific heat of exhaust gas at inlet air temperature (kJ/m

3

K)

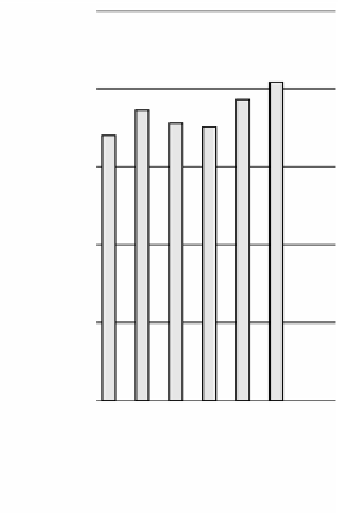

An energy saving of slightly more than 10% was achieved in the continuous

heating furnace group. The value is reasonable with respect to the unit fuel con-

sumption for this type of furnace, as it was already an energy efficient system.

An energy-saving ratio higher than 90% was achieved in the gas treatment

furnace group. The object to be heated in the gas treatment furnace itself is com-

bustible and fuel is required only for ignition. In other words, combustion of fuel

seldom occurs throughout the operation except during ignition. For this reason, the

energy-saving ratio of this group exceeded 90%.

100

H.P.I.F

Conventional F

80

60

40

20

0

FIGURE 5.85

Waste heat recovery rate.

Search WWH ::

Custom Search