Environmental Engineering Reference

In-Depth Information

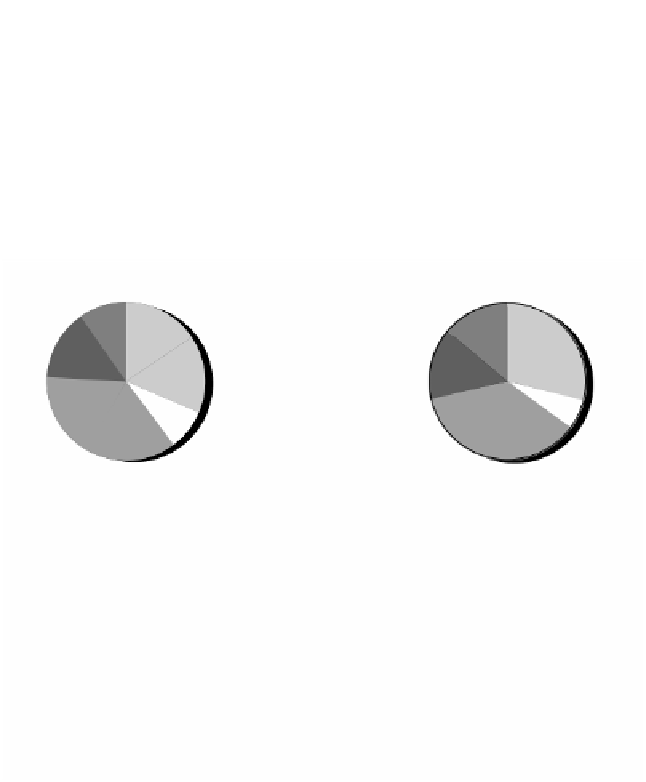

Budget of Field Test

Budget

(Equipment Expense + Management Expense)

1998 fiscal year

3.92 billion yen

1999 fiscal year

3.90 billion yen

1998 Fiscal Year

1999 Fiscal Year

H:heating furnace

M:10%

(cont)

(cont)

M:14%

L:ladle

H:29%

G:14%

H:31%

G:14%

(batch)

(batch)

58

T:heat treatment

furnace

G:gas treatment

furnace

M:melting furnace

551

T:36%

L:6%

T:37%

(batch)

L:9%

(cont)

(batch)

(cont)

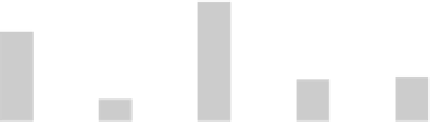

1998 Fiscal Year

25

20

15

10

5

0

T:

G:

H:

L:

1999 Fiscal Year

M:

heating furnace

heat treatment

furnace

gas treatment

furnace

melting furnace

ladle

Kind of Furnace

FIGURE 5.81

Relationship between the kind of furnace adopted in fiscal 1998 and 1999 and

number of each furnace type.

steel industry further, the share consists of 42% blast furnace makers and 38% casting

or forging steelmakers — the two groups account for 80% of the share of the iron

and steel industry. For the breakdown of the percentage of the metallic machine

manufacturing industry, the share consists of 38% of the aluminum industry and

33% of the heat-treating processing industry. To promote the application in a wider

range of industries in the future, it will be necessary to conduct analyses in industries

other than blast furnace makers in the iron and steel industry, the casting or forging

steel industry, the aluminum industry, and the heat-treating processing industry.

A case analysis on the basis of the types of fuel is shown in

Figure 5.83

.

Eight

types of fuels were involved in fiscal 1998, with LNG (13A) outnumbering others

and accounting for almost half of the total. Liquid fuels accounted for only a little

Search WWH ::

Custom Search