Environmental Engineering Reference

In-Depth Information

H

extsegments

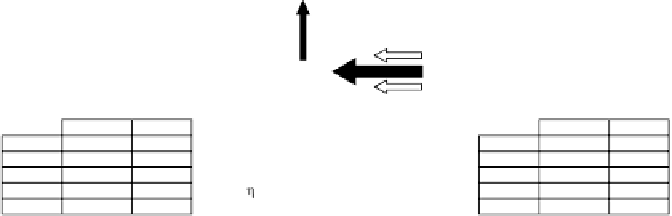

= 410 kw

±

85 kw

NATURAL GAS (HTAC97)

Flue gas: 877 Kg/h

H

flue

= 380 kw T

flue

= 1220

°

C

H

losses

= 140kw

±

85 kw

Lambda = L1

Gas = 47 kg/h H

gas

= 580 kw

Comburent = 830 kg/h H = 350 kw Tin = 1300

°

C

vol% dry

vol% wet

vol% dry

vol% wet

CO2

O2

N2

H2O

NOx

20.5

2.2

77.3

0.0

140 ppmvd

14.4

1.6

54.4

29.6

CO2

O2

N2

H2O

NOx

7.6

23.0

69.5

6.4

19.5

59.1

15.0

H

in

= H

air

+H

gas

= 930 kw

= 35%-53%

110 ppmvd

H

extsegments

= 400 kw

±

30 kw

HEAVY FUEL OIL (HTAC98)

Flue gas: 816 Kg/h

H

flue

= 350 kw T

flue

= 1240

°

C

H

losses

= 160 kw

±

80 kw

Lambda = 1.15

HFO = 51 kg/h H

hfo

= 580 kw

Comburent = 765 kg/h H = 330 kw Tin = 1320

°

C

vol% dry

vol% wet

vol% dry

vol% wet

CO2

O2

N2

H2O

NOx

24.4

1.4

74.1

0.0

215 ppmvd

18.9

1.1

57.7

22.3

CO2

O2

N2

H2O

NOx

7.2

23.4

69.5

0.0

70 ppmvd

6.2

20.1

59.7

14.0

H

in

= H

air

+H

gas

= 910 kw

= 35%-53%

H

extsegments

= 415 kw

±

40 kw

COAL (HTAC99)

Flue gas: 871 Kg/h

H

flue

= 360 kw T

flue

= 1230

°

C

H

losses

= 105 kw

±

40 kw

Lambda = 1.2

Coal = 66 kg/h H

coal

= 580 kw

Comburent = 675 kg/h H = 300 kw Tin = 1350

°

C

Transport air = 130 kg/h T = 40

°

C

vol% dry

vol% wet

vol% dry

vol% wet

CO2

O2

N2

H2O

NOx

25.5

3.1

71.3

0.0

320 ppm

20.8

2.6

58.3

18.2

CO2

O2

N2

H2O

NOx

9.5

23.1

67.4

0.0

100 ppmvd

8.1

19.7

57.2

15.1

H

in

= H

air

+H

coal

= 880 kw

= 43%-53%

Bumout

99.40%

FIGURE 2.103

Heat and mass balance of the furnace.

2.5.3.4.2 Gas Composition

The gas composition profiles show smooth gradients as was already found in the

previous HTAC trials for natural gas and oil. Almost the whole furnace volume is

filled with combustion products with the flue gas composition. Combustion seems

Search WWH ::

Custom Search