Environmental Engineering Reference

In-Depth Information

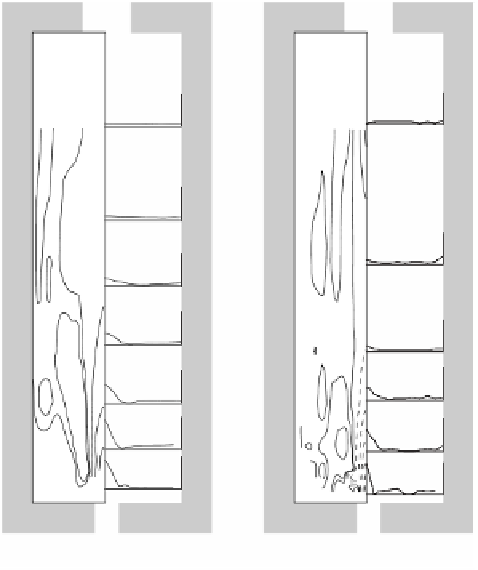

to take place in large furnace volume. To compare the previous trials with the

HTAC99 in the following figures the results of the HFO flame are reported together

with the gas composition profile in the coal flame.

on the left side and in the HFO flame on the right side. The furnace is filled with

combustion products at 3% O

2

. Practically everywhere in the furnace this O

2

level

is measured. Only at the comburent inlet high O

2

concentrations are measured (up

to 23% vol. dry).

25

25

0

0

25

2

2

25

25

0

2

0

2

25

25

0

25

0

25

5

1.5

2

1

1.5

0

25

0

25

1

25

25

2

15

0

0

COAL Flame

HFO Flame

FIGURE 2.104

Oxygen concentration coal flame (Vol%, dry).

Carbon monoxide

—

Figure 2.105

shows the CO concentration in the furnace

for the coal flame and HFO flame. It reported the 5000 ppm contour line that may

be considered the flame boundary. On the fourth traverse (133 cm from the front

wall) high CO concentrations were measured; in the fifth traverse (205 cm) CO

up to 3000 ppm was measured. From these measurements, a flame length of almost

2 m can be estimated. This flame length matches with the “visible flame” length;

a clear flame was present until the fourth segment (205 cm). Carbon monoxide

emissions were below 50 ppm at the chimney. The HFO flame shows a similar

flame length. However, on the first traverse a second peak in the CO concentration

was measured (on the oil jet boundary at the wall side). The NG and LFO flames

had a clearly different CO profile. High CO concentrations were measured farther

downstream in the furnace and both NG and LFO flames seemed to have a much

Search WWH ::

Custom Search