Environmental Engineering Reference

In-Depth Information

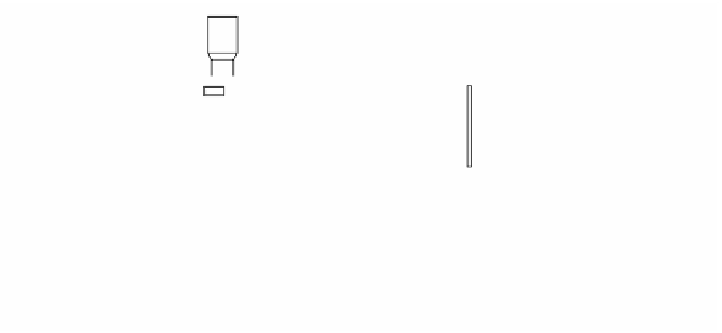

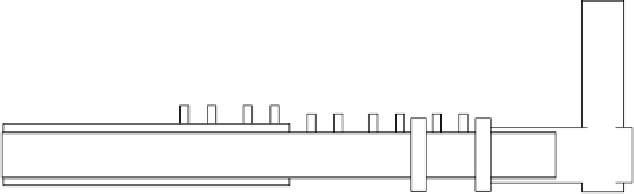

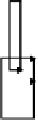

furnace, the emission behavior of volatile matter can be simulated. Under such

variable factors as the types of coal, the temperature of combustion air, and the

oxygen content, the oxygen ratio, tests are conducted by means of sampling and

Exhaust gas

Filter

to Gas anal

y

zers

Coal feeder

in

out

N

2

Cooling water

Air

Air

Cooling water

Sampling port

in

out

Natural gas

Sampling probe

Window

Water cooled section

Air+O

2

120mm

Thermocouple

Thermocouple

2108mm

FIGURE 2.95

Outline of horizontal reaction furnace of pulverized coal of high temperature

and high oxygen content.

analysis of reacting particles and gases and by optical measurement of instantaneous

particle temperature.

temperature of particles and the reaction ratio of volatile matter (VM) and fixed

carbon (FC) in the direction of the center of furnace under the test conditions: the

kind of coal (WT coal); the air temperature (1300 K); the oxygen ratio (0.8); and

the oxygen content (21%). This figure shows that pulverized coal, when injected

into the furnace, abruptly emits volatile matter and burns, and according to the

elevating particles temperature, O

2

is consumed and CO

2

, CO, and H

2

are generated.

As shown in this figure, as abrupt emission of volatile matter occurs under such

high temperature reaction as these test conditions, we assumed the following rate

constant model (2.28) for quantitative evaluation of emission rate of volatile matter

from the ratio of remaining volatile matter in reacting particles obtained by the first

sampling port.

x

t

=

k

(2.28)

where

x

is the reaction ratio of volatile matter,

t

is the time, and

k

is the reaction

rate constant.

E

RT

p

−

kk

=

0

exp

(2.29)

Search WWH ::

Custom Search