Graphics Programs Reference

In-Depth Information

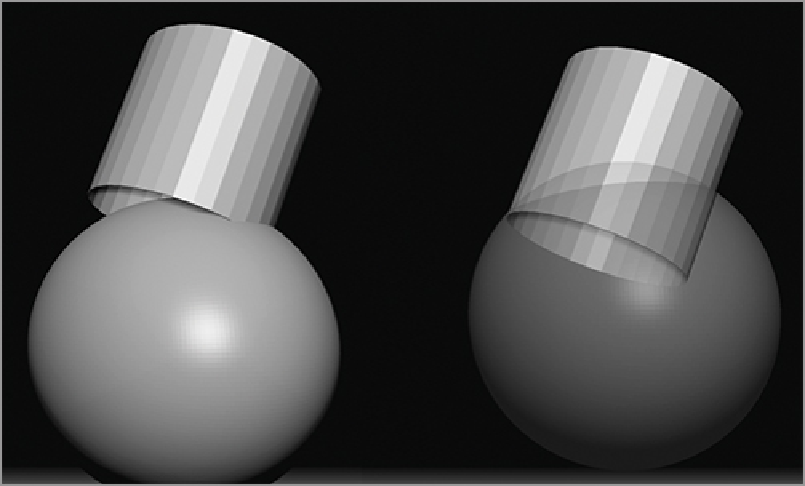

Figure 11-19:

The cylinder here will not print because it is not water-tight. This can be resolved by coun-

tersinking the cylinder into the sphere until the hole is contained inside the volume of the sphere.

Workable File Sizes

In addition to being aware of the need for a thickness and watertightness in your models, you must also be

aware of file sizes. Many 3-D printers have a file-size limit for the software. This limit improves with each

machine but generally an OBJ with many millions of polygons can easily weigh in at hundreds of megabytes

of data, whereas an average file-size limit for the printer software might be around 200 megs. You can also

speed up the printing process and reduce the chance of the printer crashing in the middle of the process if

the file sizes are smaller.

To deal with this discrepancy between file size and software limits on the machine, you will need to

decimate the models. Decimation allows the computer to remove polygons in areas of low detail while leav-

ing them in areas of high detail (

Figure 11-20

)

. This means you retain all of your fine detail while lowering

the overall poly count and file size. As we saw in Chapter 9, “Painting the Forest Spirit,” ZBrush uses the

plug-in Decimation Master to accomplish this, and we will take a detailed look at it later in this chapter.

Figure 11-20:

Here you can see the impact on decimation to the poly count. When performed correctly, the

decimation process does not impact the fine details. The head on the left is 1 million faces while the one on

the right is decimated to 200 thousand.

Search WWH ::

Custom Search