Biomedical Engineering Reference

In-Depth Information

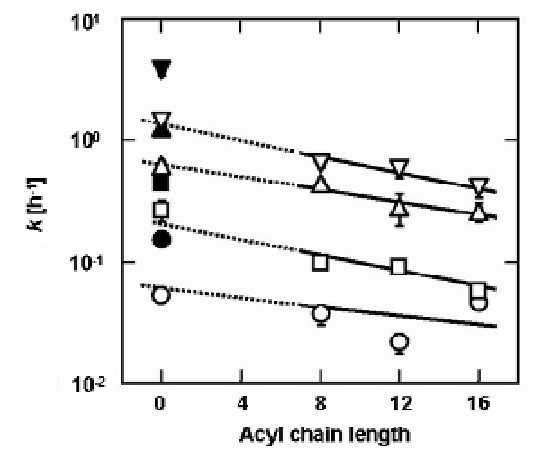

linoleic acid, there was a tendency for the

k

value in the presence of ascorbate with a larger

acyl chain length to be slightly smaller. The

k

value for linoleic acid mixed with ascorbic acid

(the acyl chain length equal to zero) seemed to be greater than that for linoleic acid mixed

with the acyl ascorbates at any temperature. As mentioned above, the

Y

0

value reflects the

initial state of the substrate, which affects the induction period. The large

Y

0

value indicates

the elongation of the induction period. The

Y

0

values for the additives were greater than that

for linoleic acid with no additive although there were some exceptions. This indicated that the

addition of an additive delayed the induction period in the oxidation process of linoleic acid.

The temperature dependence of the rate constant

k

was analyzed based on the Arrhenius

equation (Eq. 4). The Arrhenius plots using the results shown in Figure 18, in each case,

produced a straight line to evaluate the apparent activation energy,

E

, and the frequency

factor,

A

, from the slope and the intercept of the line, respectively. The

E

values for linoleic

acid mixed with every ascorbate were 50 to 70 kJ/mol and there was a tendency for

E

value to

decrease with increasing acyl chain length. The

A

values for linoleic acid mixed with the

ascorbates were smaller than that for linoleic acid with no additive or mixed with ascorbic

acid. The

A

value also decreased with increasing acyl chain length. This would indicate that

the presence of acyl ascorbate lowers both the height of the energy barrier for the oxidation of

linoleic acid and the probability of the reaction resulting in the oxidation of linoleic acid.

Figure 18. Relationship between acyl chain length of ascorbates and the rate constant

k

at (

{

) 37, (

)

50, (

U

) 65 and (

V

) 80

o

C. Open symbols represent the rate constants (mean ± standard error) for the

oxidation of linoleic acid mixed with various ascorbates, and the closed symbols that for no additive.

7. Application of Acyl Ascorbate for Microencapsulation

of a Lipid

Microencapsulation of a lipid with a wall material is a promising technology in the food

and other industries [65]. Microencapsulation of polyunsaturated fatty acid or its acylglycerol

suppresses or retards its oxidation [62, 66-68]. Microencapsulation consists of emulsification

of a core material such as a lipid with a dense solution of a wall material such as a