Biomedical Engineering Reference

In-Depth Information

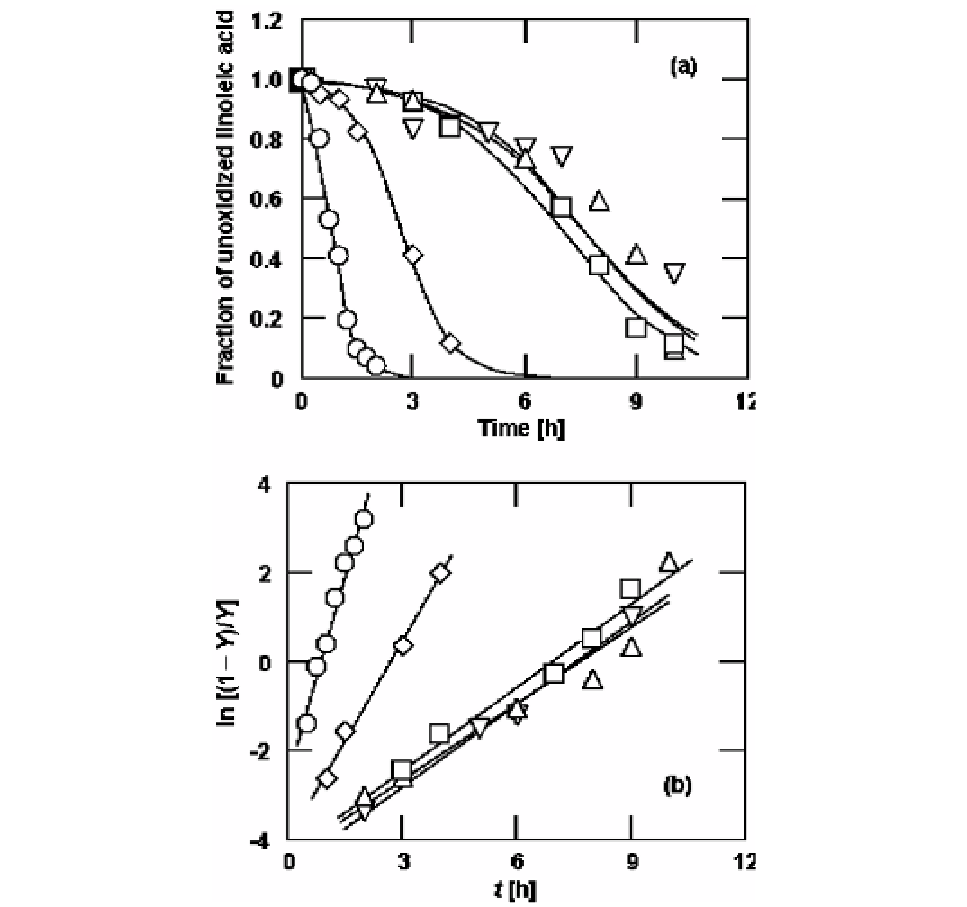

Figure 17. (a) Oxidation processes of (

{

) linoleic acid with no additive and that mixed with (

)

ascorbic acid, (

) octanoyl ascorbate, (

U

) lauroyl ascorbate or (

V

) palmitoyl ascorbate at the molar

ratio = 0.05 and at 80

o

C. The solid curves were drawn using the

k

and

Y

0

values estimated in Figure

17(b); (b) Determination of the rate constant,

k

, in the rate expression of the autocatalytic type at 80

o

C

and with the molar ratio = 0.05. The symbols are the same as those in Figure 17(a).

Y

denotes the

fraction of unoxidized linoleic acid. The solid curves were drawn based on Eq. 10.

where

Y

0

is the initial fraction of unoxidized substrate and determines the induction period

due to the mathematical nature of the equation. The applicability of Eq. 9 to the oxidation

processes of linoleic acid mixed with various ascorbates was examined. Linear plots of ln [(1-

Y

)/

Y

] versus

t

for the oxidation process are shown in Figure 17(b). Based on a linear

regression analysis, the

k

and

Y

0

values were determined from the slope and the intercept,

respectively. The

k

and

Y

0

values for the oxidation processes of linoleic acid at 37, 50 and

65

o

C were also estimated in the same manner. Figure 18 shows the relationship between the

acyl chain length of the ascorbates and the

k

value at various temperatures. At any

temperature, the

k

value for linoleic acid with no additive was greater than that for LA with

ascorbic acid or ascorbate. When octanoyl, lauroyl or palmitoyl ascorbate was added to