Biomedical Engineering Reference

In-Depth Information

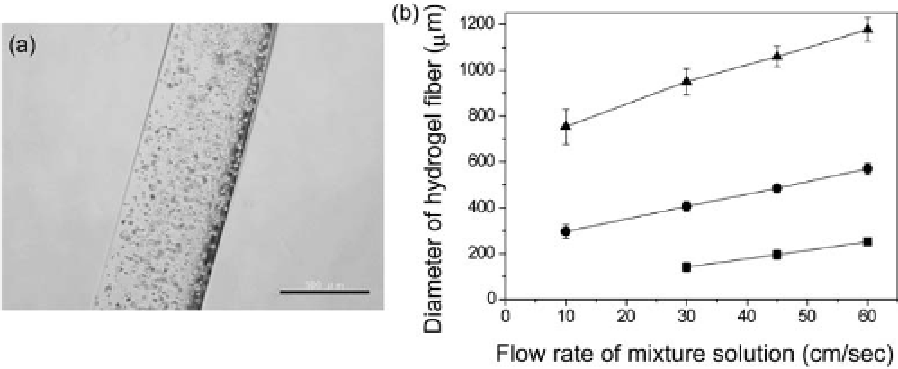

Figure 13. (a) Photograph of a BEC-enclosing Ca-Alg/gelatin fiber. Bar: 500 μm. (b) Diameters of Ca-

Alg/gelatin hydrogel fibers as a function of the flow rate of the Na-Alg/gelatin mixture and the diameter

of the needles, (■) 270, (●) 480 and (▲) 940 μm in diameter) from which the mixture was extruded.

The flow rate of the 100 mM CaCl

2

solution was fixed at 33.9 cm/s (Reproduced with permission, from

Sakai S et al. Biomacromolecules [75] @ 2008 American Chemical Society).

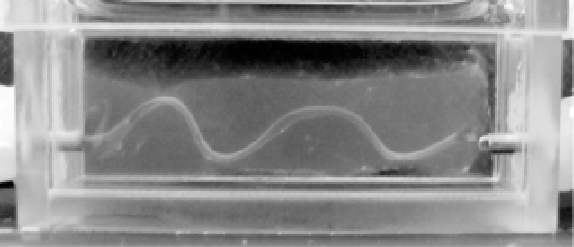

Figure 14. Photograph of the wavy-shaped channel developed in collagen gel by degrading the cell-

enclosing alginate fiber (Reproduced with permission, from Sakai S et al. Biomacromolecules [75] @

2008 American Chemical Society).

Cell Encapsulation in Ca-alginate Gel Fibers

It was also of interest to determine whether it is possible to prepare cell-enclosing

microcapsules using the aqueous solution containing dissolved multivalent cations such as

calcium ions as an ambient co-flowing liquid. It was not possible because the extruded

sodium-alginate solution instantaneously gelates after contacting the multivalent cations in

aqueous solution. We obtained cell-enclosing alginate fibers when we injected cell-

suspending aqueous alginate solution into a co-flowing 100 mM CaCl

2

solution (Figure 13a).

Similar to the droplet production in liquid paraffin, the diameter of the fiber is controllable by

changing the flow rate of ambient liquid and the diameter of the needle from which the cell-

suspending alginate solution is extruded (Figure 13b). One possible application of this cell-

enclosing alginate fiber is use it as a template for a vascular-like structure previously

developed using biocompatible hydrogels

in vitro

[75]. Due to the flexibility of alginate gel

fibers and their ability to degrade using alginate lyase, it is possible to develop a tubular