Biomedical Engineering Reference

In-Depth Information

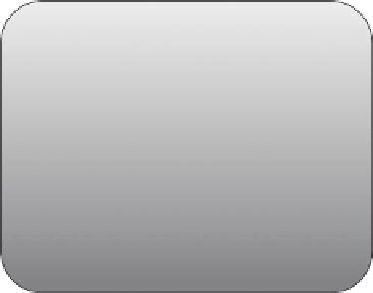

9.9 m

Work

bench

Tool box

CC

C

Sink

1.8 m

C

Drilling

machine

Band saw

HP

Diamond

saw

1.8 m

CC

HP

Vent

trunk

1 m

C: Cabinet

HP: Hydraulic pump

7.3 m

(a)

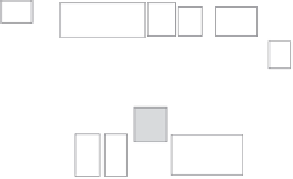

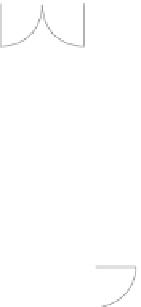

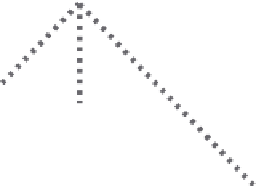

Drill stage

Diamond drill

Sample

45°

45°

10 cm

25 cm

Real-time

instruments

WRASS,

CPC 3007

Operator

(b)

FIGURE 12.11

Schematic of the laboratory depicting the location of the drilling machine

(a) and schematics of sampler arrangement for drilling and the drill stage (b). (Adapted from

Bello, D. et al. (2009b), Exposures to nanoscale particles and fibers during handling, pro-

cessing, and machining of nanocomposites and nanoengineered composites reinforced with

aligned carbon nanotubes, International Committee on Composite Materials 17, Edinburgh,

Scotland.)

(TP), and a wide range aerosol spectrometer system (WRASS). Additionally, particles

were sampled using a precipitator and subsequently analyzed by electron microscopy.

The results showed that drilling may generate substantial exposure to nanoscale

and submicron particles, in which higher exposures tend to be generated at higher

Search WWH ::

Custom Search