Biomedical Engineering Reference

In-Depth Information

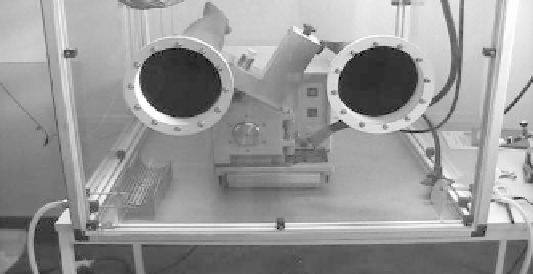

FIGURE 12.10

A small scale shredder with aerosol sampling lines in a glove box. (Courtesy

of I U TA.)

collected by electrostatical precipitation for subsequent SEM analysis. No release of

free CNT or CNT-agglomerates was observed but matrix material (PA, polycarbon-

ate, and polyethylene) with embedded CNT was observed.

Park et al. (2009) conducted the investigations of nanoparticle release during

grinding directly at a production facility, here for silver nanoparticles. The silver par-

ticles were produced in liquid and dried before grinding. The grinder is not further

described in the paper. Significant release of nanosilver particles in the size range

around 40 nm was observed when the grinder hatch was opened but not at other time

periods. Hence, it is concluded that grinding should be conducted inside airtight

systems that are placed in well ventilated rooms.

A few studies investigating shredding and grinding as possible sources of nano-

objects have been investigated but mainly in an exploratory way. Some process-

related studies and basic agreements are needed before starting any international

harmonization efforts .

12.2.6 d

rilling

Drilling is understood as a mechanical process where high speed mechanical shear

forces are used to produce a hole. Release from drilling is effected by composite type,

speed (rpm), sample thickness, and dry versus wet conditions (Bello et al. 2010). Wet

drilling can be accomplished by continuously spraying the sample composite with

distilled water leading to reduced heat.

Bello et al. (2009b) investigated in a study the airborne exposures to nanoscale

particles and fibers during solid core drilling of base alumina and CNT-alumina

composites. They considered the composite type (base alumina and CNT-alumina),

diamond drill diameter (1/4” and 3/8”), drill speed (725 and 1,355 rpm), and dry and

wet drilling. A schematic layout of the research laboratory is shown in Figure 12.11,

above. Drilling exposure data were generated during a single session with each five

replications. The instrument inlets were positioned (a) 10 cm from the potential emis-

sion source or (b) in the breathing zone of the operator (Figure 12.11b). Measurements

of airborne particles were accomplished by FMPS, APS, CPC, thermal precipitator

Search WWH ::

Custom Search