Abstract

The objective of the research project was to present new possibilities of accessibility and usefulness analysis in virtual designing of the work environment for a disabled person. This new computer tool of graphic record of anthropometric and biometric data of the set of layers was employed for a number of spectacular analyses essential for the designing practice. Results of the following investigations were presented: transfer from the wheelchair into the car of a disabled person and the accessibility of the car interior for a disabled driver, accessibility of a supermarket space for a person on a wheelchair, accessibility of furniture and equipment within the space of a typical kitchen meeting the requirements of universal design. The objects of investigations and analyses were transferred to the virtual environment of the ergonomic module of CATIA v5 computer system.

Introduction

The objective of the research project was to present new possibilities of accessibility and usefulness analysis in virtual designing of the work environment for a disabled person.

The demand for empirically verified and systematised design database taking into consideration specific requirements and possibilities of disabled persons has not been fulfilled so far.

Heterogeneity of expectations and specificity of needs cause that it is difficult to define and arrange hierarchically requirements for design objects utilised by handicapped subjects [4, 8, 9, 14, 15].

A special graphic database of ergonomic data was employed. Such database of an-thropometric and biometric data for a disabled person sitting on a wheelchair or in a car seat was collected in the course of earlier investigations conducted to develop advanced tools of virtual engineering [4, 5, 6]. It comprises an integrated 3D model of arms’ reaches and limiting forces of arms of a person. Ranges of acceptable forces in the graphic 3D space of manipulations can be processed dynamically from empirically obtained ranges of limiting forces following adoption of one of known models of the impact of such factors as: age, training and type of loading on human safety [11, 25]. The method of model development has an innovative character [26] and was awarded a number of international distinctions.

Structure of Graphic 3D Database Regarding Arm Reach and Forces of a Male Person Sitting on a Wheelchair

Empirical data about reaches and forces of arms were obtained on the basis of investigations of a paraplegic sitting on an active wheelchair or on a seat of a car from segment B. The subject of investigations was a male 32 years of age, 182 cm height and 72 kg of weight with spastic paralysis of Th5 acuteness of the trauma and unequal length of upper limbs (right 72 cm, left 68 cm). Anthropometric measurements of the subject of investigations were close to the 50 percentile male of American population [18,23]. The damage of the spinal column and differences in limb lengths and mobility of joints resulted from a traffic accident at the age of 18. In the course of experiments, the disabled person was sitting on the cushion of the SET active wheelchair manufactured by Kaleb Company (Poland) with non-foldable frame inclined 3o down in the seat plane and 87o angle of the backrest.

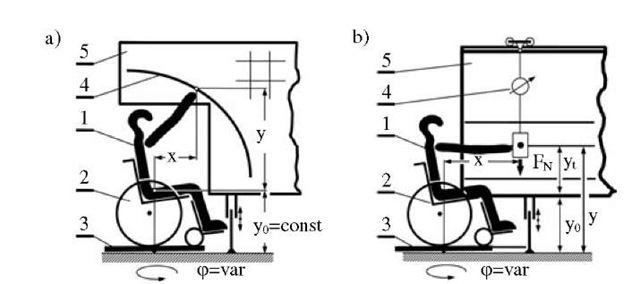

The experimental station for static and dynamic reaches of arms (Fig.1a) consists of a circular plate of a measuring protractor I in the axis of which in the reference point SRP of a person 3, a wheelchair 2 was placed (height y0 = 55 cm). The protractor with the wheelchair (or a car seat) and a sitting man can turn in relation to the stationary vertical table 5. The table plane passes through the reference point SRP. Biomechanical studies of the man’s forces were conducted on the assumption of the vertical direction downwards of the force action.

The method of the investigations of forces is presented in Fig. 1b. The seat arrangement and position of the table in relation to the seat are identical as in the zone measurements of the arm reaches. The table positioning mechanism at a specific height guarantees possibilities of taking force measurements at three preset levels y: the head (eyes y = 67 cm), shoulders (y = 42 cm) and waist (waist y = 13 cm) of the disabled person against the SRP point. Forces were measured at the following distances: x from 40 to 80 cm; Ax = 10 cm in relation to the reference point SRP. Results of measurements of arms’ reaches in the (x, y, 9) system and of arms’ forces in the f(x, y, 9) system were converted both numerically and graphically. Numerical data x,y,9 obtained from our own measurements was archived electronically and was used to plot curves of arm reaches in measurement planes at set heights of axis Z.

Individual diagrams of arm reaches were then represented by a spline type curve and a Non-Uniform Rational B-Spline (NURBS) surface was spread on the set of curves. In the analysis of forces, the numerical data FN = f(x,y,9) obtained from transformations were archived in an electronic form. In this way, a biomechanical-anthropometric model was developed of a contour type structure describing free surfaces of a layer with FN = const. taking advantage of heterogenous B-spline rational functions.

Fig. 1. Block diagram of a measurement stand and method of arm reaches (a) and arm forces (b) of a disabled person sitting on a wheelchair in a 3D space of geometrical dimensions x, y, 9: (1) – handicapped person; (2) – active wheelchair; (3) – measuring protractor, (4) – reach curve (a) or measuring dynamometer (b); (5) – table.

The outcome of the performed investigations is also a certain model of biome-chanical limiting external loads of the right arm of a handicapped person sitting on a wheelchair. Values of numerical data FN= f(x,y,9) obtained from transformations were archived in electronic form.

Data sets of ‘crude’ values of FN force in the distance function x at constant height values y and angle of rotation 9 obtained from four-parametrical measurements require "reverse" calculation processing in order to obtain three-parametrical record of the x, y, 9 surface of the FN=const. layer. It is a certain biomechanical-anthropometric model of contour line structure describing free layer surfaces of FN=const.

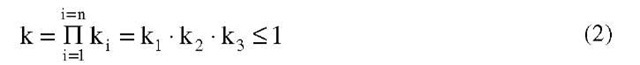

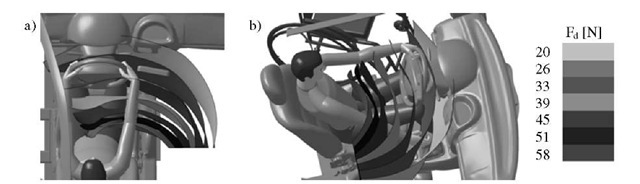

Figure 2 present 3D images of sets of layers of constant force FN sought in this study for the right upper limb of a sitting disabled male person.

On the Figure, the external layer representing the reach of the right arm of the examined disabled man was determined in an earlier study [4]. In this way, a common 3D geometrical representation of anthropometric characteristics of the reach of arms and of biomechanical characteristics of the force of the arm was obtained.

For further analysis the transformation of measured data are needed. There are several different methods of transformation of limiting forces resulting from Fg measurements to allowable Fd forces safe in definite conditions of work [1,7,10,11,25].

They are brought to the reduction of the limiting force value Fg by the introduction of the product of impact coefficients:

where: the product of impact coefficients is described following

Impact coefficients take into account most commonly: age and gender (k1), training (k2) and kind of loading (k3) and, in this way, it is possible to re-scale values of forces determining force zones. The above presented method of elaboration of graphic 3D of anthropometric and biomechanical database [6] will be used in future studies.

Values given on the scale in Figure 2 have been converted from values of limiting forces Fg obtained in the course of investigations to values of allowable forces Fd using the above-described coefficient methods [2,11]. Using method [6], the following values were obtained for the performed task of reaching by a person sitting on a wheelchair Fd=krk2-k3-Fg=0.85-0.75-0.4-Fg=0.255-Fg. Figure 2 presents rescaled zones assuming the dependence Fd=0.25-Fg.

Fig. 2. Set of surfaces determining zones of occurrence of constant forces of the right arm against the external surface of the arms’ reach

Virtual Analysis of the Accessibility to Workplaces of a Handicapped Person on a Wheelchair

The presented graphic model of integrated anthropotechnical and biomechanical data was used in: (1) the analysis of accessibility of a disabled person to technical means of sale space in a supermarket (shelves, refrigerators), (2) the analysis of transfer from a wheelchair into the personal car of a handicapped driver and analysis of accessibility to the so called comfort zones inside the car and (4) the analysis of kitchen accessibility. All analyses were performed in the ergonomic module of the CATIA software system. The anthropometric model (phantom) was characterised by dimensions corresponding to the real dimensions of the object of experiments.

Sales Space in a Market

The availability of the sales space in a market for disabled persons with advanced mobility dysfunction (e.g. those who move with the assistance of active wheelchairs) is very limited. These constraints occur due to definite range of reach and strength possibilities of human upper limbs in a specific for a supermarket element arrangement of the "man – wheelchair – element" system of sales hall equipment. The arrangement of the sales space in supermarkets is based on principles of merchandising sales intensification which remain in stark antinomy with principles of ergonomics. Groups of the most expensive products and products of the greatest rotation are placed on market shelves on the basis of the optimisation of product perception on the shelf at the height of sight of a standing, able-bodied customer (1.2 to 1.6 m). Unfortunately, it is different from the perception perspective of a disabled person sitting on a wheelchair. The imposed traffic direction (market areas on the right-hand side of the route) for first necessity goods, furthermost from the entrance is also not very favourable for all customers. The zone analysis of the force reach for the right hand revealed that the object manipulation in the course of picking an article from the centre shop shelf takes place within a restricted interval of force zones (in Figure 3, zones of 51 and 58N force values have been eliminated) due to limited possibilities of the approach of the wheelchair to the stand.

Manipulations on the top shelf are situated at the boundary of zone ranges with force values of 20 and 28N which makes handling heavier products difficult, uncomfortable and unadvisable. Since no data regarding the distribution of force zones of the bottom shelf were available, this shelf was not analysed.

Fig. 3. Visualization of the vision field and force zones of a male with a disability in supermarket surroundings

Analysis of Car Utilisation by a Disabled Person

It is evident, from the analysis of processes of transfer from the wheelchair onto the car seat as well as actual driving of the car by a handicapped person, that critical er-gonomic activities for the appropriate system configuration: disabled Person – active Wheelchair – personal Car (P-W-C) are as follows:

• dynamic transfer of a person from the wheelchair onto the car seat;

• loading of unfoldable wheelchair frame into the car as the assembly of biggest dimensions and weight (after dismantling drive wheels);

• driving and operating car devices in the so called ‘comfort zones’.

Assessment criteria of adjustment of the support devices of the P-W-C system comprise, primarily, man’s somatic features (position of a person during handling of devices, spatial restrictions, reaches of limbs, forces exerted by limbs) [20].

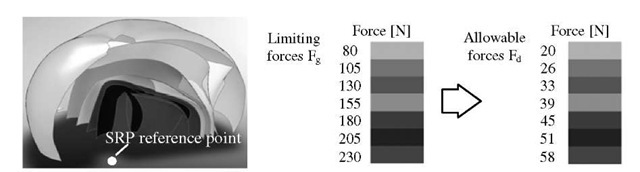

A phantom from the CATIA v.5 system of dimensions complying with those of a handicapped person was applied. Earlier prepared 3D models of a real car from segment B (Renault Thalia/Clio) as well as of an active wheelchair (in CAD, Solid-Works, RhinoCeros and CATIA v. 5 systems) were employed in our investigations. The form and arrangement of dimensions of two graphic representations of anthro-pometric features as well as reaches of upper limbs and biomechanical forces were obtained on the basis of empirical studies of a disabled person sitting on the wheelchair and on the car seat. Each of these representations of features reminds by way of their mutual overlapping "an onion" with its centre in the SRP anthropometric measuring point. Figure 4 compares system cross-sections of force layers of a handicapped person sitting in a wheelchair and on a seat of a car.

Fig. 4. Comparison of representations of force features of a disabled person sitting in a wheelchair (a) and on a seat of a car (b)

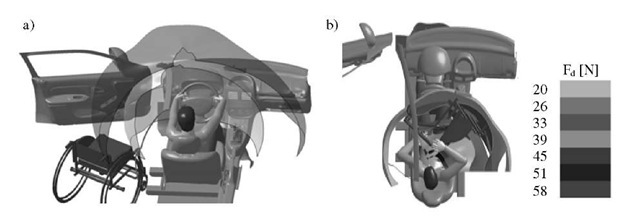

Authors analysed the process of loading objects into the car. The frame of the wheelchair is transferred by the right hand from the outside into the interior (on the passenger’s seat or on the back seat) of the car (Fig. 5).

Fig. 5. Position of the static and dynamic reach of the right upper limb (a), loading of the wheelchair frame (b)

When loading the wheelchair, arms’ dynamic reach must be employed. A driver sitting on the seat is not able to reach the wheelchair without breaking his back away from the seat backrest (Fig. 5a).

Other activity of disabled person is the process of transfer from a wheelchair into a car, significant loads occur. A force analysis of putting the frame of an active wheelchair into a car by a driver with disability is presented in Figure 5b. The comparison of the wheelchair frame gravity forces (weighting about 8 kg) with acceptable strength possibilities of the driver shows that the value of the permissible force was exceeded two times.

The analysis of servicing operations during driving is performed in the so called comfort zones [3. 12, 16, 17, 19, 21]. Figure 6 shows the results of analysis of force possibilities of loading of the steering-wheel and the gear lever by the driver in static position. The condition of the accessibility of arms’ reaches is fulfilled.

Fig. 6. Force zones during manipulation of the steering-wheel (a) and gear lever (b)

Investigations on the Accessibility and Field of Vision of a Disabled Person Sitting on a Wheelchair in Kitchen Virtual Environment

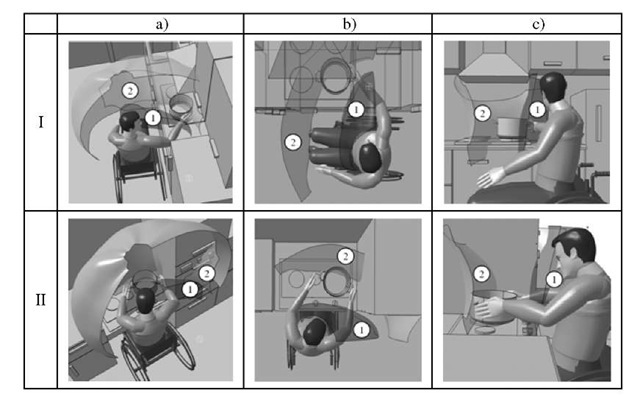

A standard kitchen usually does not fulfill the expectation and requirements of a disabled user. Interactions between the spatial structure of the work station and the user of the kitchen sitting on the wheelchair prevent him/her to adapt typical ergonomic positions. The sitting position on the wheelchair and lack of recesses in furniture as free space for feet makes close approach of the wheelchair to the front of furniture and equipment impossible and prevents the user from adopting a position identical with the standing position of other kitchen users. The sideways approach to furniture and equipment enforces an unnatural position of single-handed work, usually at the limit of arm reach with respect to dynamic leaning. In this dynamic position, work is less comfortable and the body position less stable due to the lack of the back support at the height of loins. It is true that at the wheelchair sideways approach to furniture (Fig. 7-Ia), manipulation possibilities increase but, practically speaking, all manipulations must be performed with one hand – right or left – depending on the direction of the vehicle in relation to furniture (Fig. 7-Ib, Ic). Another significant limitation is connected with the arms’ reach since only the front part of the heating plate remains within the working range of arms. In addition, considerable distance from furniture causes that work is carried out with arms almost straight, limiting the applied force of the user and easily leading to rapid static fatigue. It should also be remembered that all work is performed sideways and, inevitably, when carried out long, is extremely exhausting.

In an adapted kitchen, the most important technical facilities of the kitchen equipment (e.g. gas cooker, sink) are characterised by appropriately changed dimensions. The height of the heating plate is lowered to suit the figure of the user sitting on the wheelchair. In addition, the removal of the lower part of the cupboard allows sufficient space for legs making it possible for the disabled person to access the device comfortably (Fig. 7-IIa). This position allows manipulation of kitchen utensils with both hands in the frontal half-sphere of the arms’ reach. This affords significantly better manipulation possibilities at considerably reduced required muscle forces.

The field of vision of the workplace in an adapted kitchen is better. The lowered heating plate creates better manoeuvring possibilities with kitchenware and, additionally, affords significantly better observation of the working area as well as the content of individual utensils. The field of vision of the disabled in a standard kitchen is nearly parallel to worktops and, consequently, the entire work field is seen from the side (Fig. 8a). In the case of the kitchen with adapted furniture, the field of vision is moved higher and therefore the user looks at the objects from above (Fig. 8b).

Fig. 7. Visualisation of the reach zone of the right arm and force range during manipulation at the gas cooker in a standard (I) and adapted (II) kitchen; (1) – 180 N zone, (2) – 80 N zone, grey colour – maximum range of arm reach

Fig. 8. Visualisation: a,b) of the field of vision of a disabled person during manipulations at the gas cooker and c,d) manipulations possibilities of the right arm for a standard (a,c) and adapted (b,d) kitchen

When analysing arms’ reaches, it is also important to pay attention to possibilities of manipulation with the other (in this case, right) hand. In the case of sideways work in relation to kitchen furniture (Fig. 8c), it is possible to use only one hand when operating equipment for thermal treatment as manoeuvres with the wheelchair are very difficult. In the case of the adapted kitchen, with the possibility of access to furniture from the front, the user can employ the free hand, at any moment, to move around or reach for required elements.

Conclusions

The presented original method of graphic modeling of anthropometric and biome-chanical data for the requirements of CAD systems can be applied universally in ergonomic designing of the workspace not only for handicapped persons. When designing workplaces, designers often overlook requirements and possibilities of persons with locomotive disabilities (especially with respect to accessibility within effective reaches of arms and allowable forces of arms) as well as limitations of the field of vision with regard to objects of manipulation. Drawing conclusions on the basis of the 3D graphic analysis of different situations in the workspace is relatively simple. Preparation of the model of computer simulation is quite labour-consuming.

The method presented in this work has been patented [26] and received numerous awards: Gold Medal on Seoul International Invention Fairs SIIF 2010, Gold medal on IV International Warsaw Invention Show IWIS 2010, Silver medal on Brussels In-nova: International Exhibition of Invention Research and New Tech. Eureka 2010.