6.10.

Optical flats are cylindrical in form with the working surfaces flat and are of two

types:

Type A—It has only one surface flat. The working surface of this type of flat is indicately

by an arrow head on the cylindrical surface pointing towards the working surface.

Type B—It has both the surfaces flat and parallel to each other.

Type A are used for testing the flatness of precision measuring surfaces of flats, slip

gauges, measuring tables, etc. Type B are used for testing measuring surfaces of micrometers,

measuring anvils and similar length measuring devices for testing flatness and parallelism.

These are generally made of either fused quartz (whose co-efficient of linear expansion

is not more than 0.6 x 10_6/degree at standard temperature of 20°G) or borosilicate glass (whose

co-efficient of linear expansion is not more than 3.6 x 10-6/ degree at standard temperature of

20°C). This glass is clear and colourless and free from inclusions and defects like bubbles,

internal strains and extraneous matter.

The cylindrical surfaces of the optical flats are finished by grinding and the working

surfaces are finished by lapping and polishing process. The finishing is done to such an extent

that straight and parallel interference fringes are produced when the optical flat is viewed

under a monochromatic source of light by placing it in contact with a reference flat surface.

Their edges are generally bevelled to 45° by a suitable grinding or polishing process so that

the edges are free from any chips.

The working surfaces of each Type B flat are inclined to each other by about 5 minutes.

In order to avoid the optical flats from shocks, dust and moisture during transportation

and storage, these are generally housed in a wooden box having seating lined with velvet.

Depending on their accuracy, i.e. tolerance on flatness for Type A and tolerances on

flatness, parallelism and thickness for Type B, these are classified as :

(i) Reference Grade or Grade I, and

(it) Working Grade or Grade II.

For type A optical flats, their diameter and grade are important and, therefore, these

are usually designated by the above two ; whereas for type B flats, their thickness and grades

are important and, therefore, their designation includes these two items.

As per IS : 5440—1969, the dimensions of optical flat of type A and grades I and II can

be 25 x 10, 30 x 10, 50 x 15, 75 x 20, 100 x 25, 125 x 30, 160 x 35 (diameter in mm x thickness

in mm) and the dimensions of type B optical flats of either grade can be 25.0 x 12.000,

25.0 x 12.125, 25.0 x 24.250, 25.0 x 12.375, 25.0 x 24.000,25.0 x 24.125, 25.0 x 24.250 and 25.0

x 24.375 respectively. Further the tolerance on flatness should be 0.05 um for type A, Grade

optical flats of sizes upto 100 mm, and 0.10 mm for sizes 101—200 mm respectively ; and 0.01

um for type A, Grade II opticalflats and sizes upto 100 mm, and 0.20 urn for sizes 101—200

mm respectively. For type B optical flats, the tolerances on flatness, parallelism and thickness

should be 0.05 um, 0.15 urn and 0.20 u.m respectively for Grade I; and 0.10 um, 0.20 um and

0.30 u.m respectively for Grade II.

6.10.1. Testing of optical flats. As already indicated type A optical flats are tested for

flatness of working face and type B for flatness of working faces, parallelism of working faces

and thickness.

Flatness test. The flatness of the working surface of an optical flat is tested by

comparing its flatness with a master flat of known flatness or by comparing the working surface

of three separate flats of unknown flatness. The testing is usually carried out by observing the

interference fringes using monochomatic light source, the incident rays from which may be

either diffused or parallel.

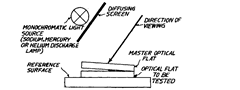

In testing with the master flat whose flatness is known, the master flat is placed over

the working surface of the flat under test (which itself is placed on some reference flat surface)

in such as manner as to form a wedge shaped air film between the two flats as shown in

Fig. 6.40.

Fig. 6.40. Setup for flatness test.

If the optical flat under test has a perfectly flat surface then the fringes observed will

be straight lines (dark and bright bands) parallel to each other. The degree of any deviation of

flatness in the optical flat under test from the flatness of the master flat is given by the

deviation of the fringes from straightness in any direction (the direction indicates the concavity

or convexity).

The fringes are generally observed in a telescope which carries a micrometer eye-piece

and in which the deviations of fringes are easily measured in terms of fringe width by means

of the cross wires.

When the master optical flat of the known flatness is not available then the testing of

flatness may be carried out by intercomparison with two other optical flats of unknown

flatness. The three flats are examined in pairs as shown in Fig. 6.41 for the interference fringes,

the testing procedure and arrangement being same as described above for testing with master

flat. The deviations from straightness of fringes are noted for three cases, i.e. when flat to be

tested is placed on unknown flat I, unknown flat I on unknown flat II, and unknown flat II on

the flat to be tested (Refer Fig. 6.41).

Fig. 6.41. Testing of optical flats.

Parallelism Test

The parallelism of the working surfaces of type B optical flats can be tested by Fizeau

Interferometer method.

In a modified arrangement of the Fizeau Interferometer method (Refer Fig. 6.42), light

from a mercury vapour lamp is focused on to an opening in the eye-piece and is partly reflected

by a beam splitter. The reflected light strikes the collimating lens which collimates it and

throws it further on the flat under test. The flat under test is placed on a table provided with

levelling arrangement. The level screws of the table are arranged such that the beam strikes

Fig. 6.42. Setup for parallelism test.

the surfaces of the flat perpendicularly. After reflection from the two surfaces of the flat under

test, the beam retraces its path. Due to the interference of the light reflected at the two parallel

surfaces of the optical flat, interference fringes are formed which can be viewed from the

eyepiece of the autocollimator. These interference fringes help in determining the degree of

flatness of the two surfaces of the flat. The difference of thickness of the flat at two points on

the adjacent fringes is equal to ^ x — microns, where u is the refractive index of the substance

of which the flat is made and X is the wavelength of the light used. This gives the optical

parallelism of the two surfaces of the flat. Since the flat is made of material of uniform refractive

index, this parallelism also represents geometrical parallelism.

6.10.2. Care in the use of Optical Flat. Before using optical flat, it should be ensured

that both flat and workpiece are clean and free from dirt, dust, oil or finger prints. This can be

accomplished by swabbing the flat and workpiece with grain alcohol and polishing their

surfaces with clean chamois or paper.

Optical flat should never be wrung on workpiece because it scratches too readily. It

should only be rested carefully on the workpiece. It should be carefully and firmly pressed

down evenly on workpiece with two fingers till interference bands become discernible. If the

flat is pressed very close to workpiece, the air wedge between the flat and workpiece will be

thin, and wider apart will be the interference bands.

Optical flat should never be slid over workpiece but lifted from it. If interference bands

are not good, flat should be lifted and set down again, applying vertical finger pressure at

various locations on the upper surface to obtain satisfactory bands. Sliding, creeping and

wringing of flat over workpiece are extremely harmful and should be avoided. It can only be

rocked and pressed.

If interference bands do not appear, it may be due to presence of dust or dirt between

flat and workpiece or by lack of sufficient polish on the work to reflect the light.

Optical Flats (Metrology)

Next post: Scales and Gratings (Metrology)

Previous post: Heterodyne Interferometry Technique (Metrology)