ABSTRACT

Nano-indentation studies using atomic force microscopy (AFM) were introduced to investigate the effects of hydrolysis degradation on mechanical properties of polyglactin 910 monofilament sutures. The polyglactin 910 sutures were immersed in phosphate buffered saline (PBS) solution of pH 5, 7.4, 10 without enzyme and pH 7.4 with esterase enzyme. After that, the samples were incubated at 37 oC under an oscillation of 80 rpm. Samples were removed for testing after 7, 14, 21 and 28 days. The effects of degradation on gradation of Young’s modulus values across fiber cross-section were studied by doing progressive nano-indentation from center to surface of cross section of the sutures. Results indicate that the pH 7.4 condition hydrolysis degradation did not have a significant impact on variation of Young’s modulus values of the polyglactin 910 sutures from the center to the surface after different degradation times. And the Young’s modulus from the original samples to sutures after 4 weeks degradation have a decreasing trend, but not including the first week. Then the SEM, FTIR and Tensile test were conducted to investigate the mechanical and chemical properties of polyglactin 910 monofilament sutures.

INTRODUCTION

At present, polyglycolide, polylactide and their copolymers are widely used as the biodegradable polymeric biomaterials [1]. For absorbable suture material, the two important factors considered are keep maximum original tensile strength as long as it is needed for wound healing and disappearance as soon as possible when the sutures have lost their tensile strength. The polyglactin 910 monofilament suture meets all the desired properties for the absorbable sutures. It is less reactive than catgut and better in tensile strength [2]. Polyglactin 910 monofilament suture is made by the copolymerization of lactide acid and glycolide acid, and it is composed of 90% polyglycolide and 10% polylactide. This suture can be used in general soft tissue approximation or ligation, including use in ophthalmic procedures, but not for use in cardiovascular or neurological tissues. As the sutures degradation, all absorbable sutures have two steps of absorption. The first is the loss of the tensile strength, and the second is the progressive loss of the suture mass until the suture is completely absorbed.

Many studies have been done on the multifilament PGLA sutures of their mechanism and macro-mechanical properties. But it is far away from the comprehensive understanding of the mechanism for the in vitro degradation of PGLA sutures, especially the micro-mechanical properties.

Experimental

Materials

Polyglactin 910 monofilament sutures were purchased from Ethicon Company (V960G), which is a 10-0 size violet monofilament suture. It is composed of 90% polyglycolide and 10% polylactide, which structure shown in Fig. 1. This suture can be used in general soft tissue approximation or ligation, including use in ophthalmic procedures, but not for use in cardiovascular or neurological tissues

Fig. 1 Repeated units of (a) polylactide, (b) polyglycolide.

In vitro degradation

Polyglactin 910 monofilament sutures were purchased from Ethicon Company (V960G), which is a 10-0 size violet monofilament suture. It is composed of 90% polyglycolide and 10% polylactide. The polyglactin 910 sutures were immersed in phosphate buffered saline (PBS) solution of pH 7.4, and then the samples were incubated at 37 oC under an oscillation of 80 rpm. After 7, 14, 21 and 28 days, the samples were removed from the PBS for the following test.

Atomic force microscope

Sample preparation

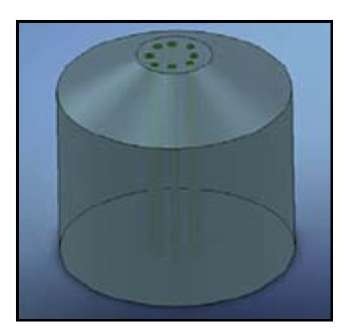

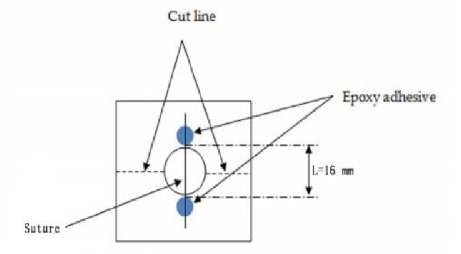

Sutures were vertically embedded in the mode as Fig. 2 with curing and low heat generation epoxy at room temperature for 12 hours. After that, the samples were cut with a ultra-microtome to get a very smooth cross section.

Fig. 2 Fibers embedded in Epoxy Matrix.

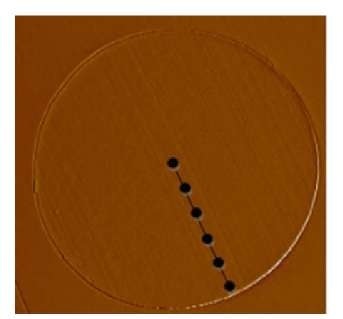

Fig. 3 Nano-indentation across the suture cross section.

Nano-indentation

The indentation was performed on the cross section of the sutures as Fig. 3, from the center to the surface. The contact mode scan was made to get the geometry images for the nano-indentation.

Surface topography

The surfaces of the samples were scanned using non-contact mode to obtain the surface topography images. Then we can get the 3D images of the previous.

Scanning electron microscope

Sutures were sputtered with gold and examined using a JEOL JSM 5610 scanning electron microscope, with a observation condition voltage of 10 kV.

Macro-scale tensile testing

According to ASTM G3822 standard, a constant rate of extension 2.54 mm/min was used for 16mmgage length sample. The limited maximum force of the load cell is 2.5 N. As Fig. 4 shows, the blue dots are the epoxy adhesive.

Fig. 4 Schematic of tensile testing sample

Fourier transform spectroscope

The sutures were arranged at the gold plate and carried out in the reflectance mode with Fourier transform infrared spectroscopy (Varian FTIR Bench and Microscope, CA, USA).

Results and Discussion

Nano-indentation

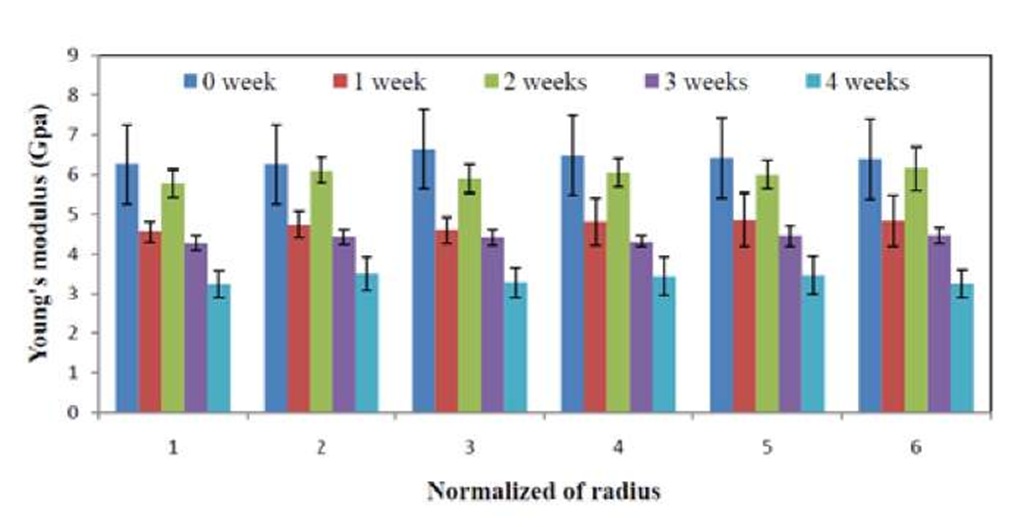

Nano-indentation were performed across the fiber radius from center to surface in Fig. 5, from which we can get the Young’s modulus at different places and different degradation times seems almost at a same level.

Fig. 5 Young’s modulus at different places and different degradation times

Fig. 6 Topography images of the sutures at different degradation times

Surface topography

Using the non-contact mode of AFM, we can get the topography images of the sutures at different degradation times in Fig. 6. It is obvious that there are changes of hydrolytic degradation at the surface. The amorphous areas are easier for degradation than crystalline areas. It is possible that the peaks of the surface are crystalline areas.

Scanning electron microscopy

SEM images of surfaces of the monofilament polyglactin 910 sutures at different degradation times are shown in Fig. 7. These images show no significant differences at different degradation weeks. Fig. 8 shows the difference between bulk and surface degradation. From Fig. 7, we can get the diameter of the sutures at different degradation times, and all of the diameters are around 27 microns, with no significant differences. It proved that the main effects of the hydrolytic degradation for polyglactin 910 monofilament sutures are bulk degradation.

Fig. 7 SEM results of polyglactin 910 sutures at different degradation days

Fig. 8 Schematic of bulk and surface hydrolytic degradation[3]

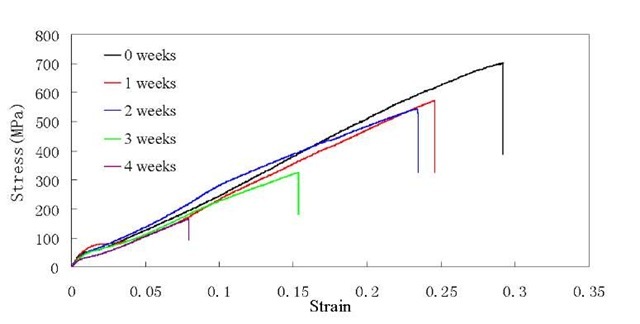

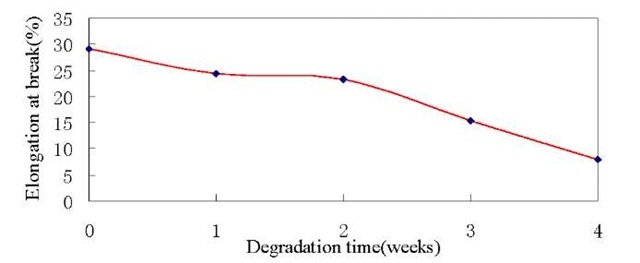

Tensile testing

Fig. 9 shows the correlation between stress and strain of the sutures. It is shown that the samples have a high tensile strength and elongation at break. Also from Fig. 10 and Fig. 11, we can see the changes of the tensile strength and elongation at break on different degradation weeks. After 4 weeks degradation in PBS solution, just about 24% of its original tensile strength and 8% of its original elongation at break is left. The results shown above might be the reason that the main degradation of the PGLA monofilament sutures in PBS solution is bulk degradation.

Fig. 9 Stress-strain diagram at different degradation weeks

Fig. 10 Tensile strength at break at different degradation weeks

Fig. 11 Elongation at break at different degradation weeks

Fourier transforms spectroscopy

Fig. 12 displays the IR spectrum of Polyglactin 910 monofilament sutures, from which we can see the C-H bonds are around 2900 cm"1 and 1400 cm"1. The C=0 bonds are around 1750cm"1, and the special O-H bonds are near the area of 3500cm"1. From original sutures to 4 weeks degradation sutures, the scope of the O-H bonds are becoming wider and wider. It is the reason that the hydrolysis degradation let the breakage of the ester bonds, after that there will produce a lot of O-H bonds.

Fig. 12 FTIR spectrum of the polyglactin 910 suture at different degradation weeks

Conclusions

The Young’s modulus of the in vitro degradation polyglactin 910 monofilament sutures from the center to the surface and at different degradation times don’t have significant differences. Also the tensile strength has a big change. The samples have a high tensile strength and elongation at break. After 4 weeks degradation in PBS solution, just about 24% of its original tensile strength and 8% of its original elongation at break is left. The 3D topography images from AFM show that there is surface degradation at the in vitro degradation. The SEM images show the constant level diameters of the sutures at different degradation times at in vitro degradation.The study shows that this degradation consists of bulk degradation and surface degradation, and the bulk degradation takes a main position in the degradation process.

![Schematic of bulk and surface hydrolytic degradation[3] Schematic of bulk and surface hydrolytic degradation[3]](http://what-when-how.com/wp-content/uploads/2011/07/tmp16119_thumb_thumb.jpg)