Effect of Degradation due to Water and Diesel Fuel:

In this study, the degradation of the SMP due to water and diesel fuel has been examined. At first, the intensity of degradation causes by water and diesel fuel has been compared. Then the progress of degradation with time due to water and diesel respectively, for the duration of one month has been investigated.

Comparison of the Degradation due to Water and Diesel Fuel with Untreated Samples: As stated earlier, the effect of water and diesel fuel on styrene based Veriflex- SMP due to immersion for 1- week has been investigated and compared with respect to each other and with un-degraded samples.

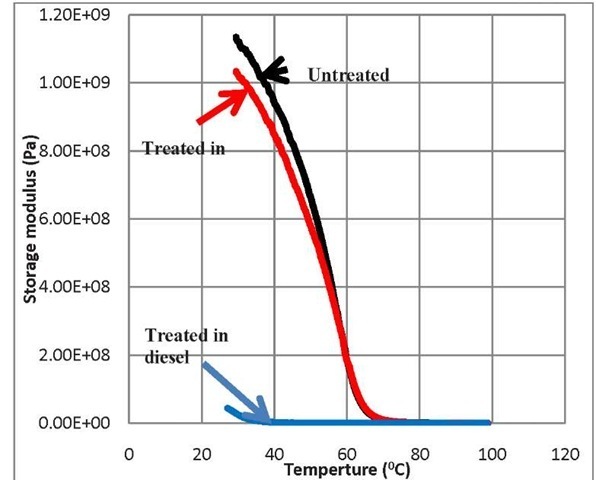

Change in Storage Modulus: The behavior of storage modulus as a function of temperature of the untreated sample and the sample immersed in water and diesel fuel for 1 week has been shown in Fig. 9.

Fig. 9: Comparison of storage modulus between Untreated and treated Veriflex- SMP

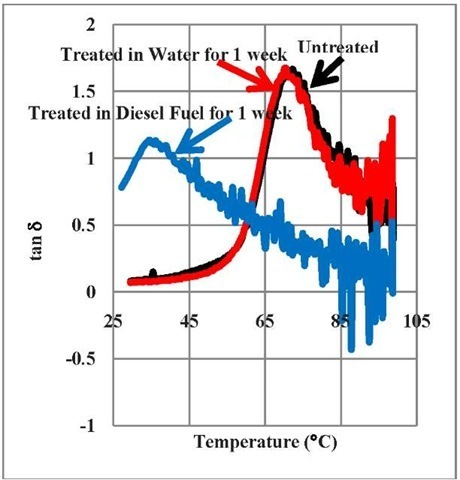

Fig. 10: Comparison of tan delta curve between untreated and treated Veriflex-SMP

From the curves shown in the Fig.9 we see that the value of storage modulus, the load bearing capacity, of the material at room temperature decreases due to exposure to solvents. We also observe a greater decrease in the value of storage modulus for the case of SMP degraded by diesel fuel in comparison to water. We found that that due to immersion in diesel fuel the storage modulus decreases by 96.1% whereas, the decrease of storage modulus due to immersion in water is around 8.85% in comparison to untreated samples. Change in Glass Transition Temperature, Tg:

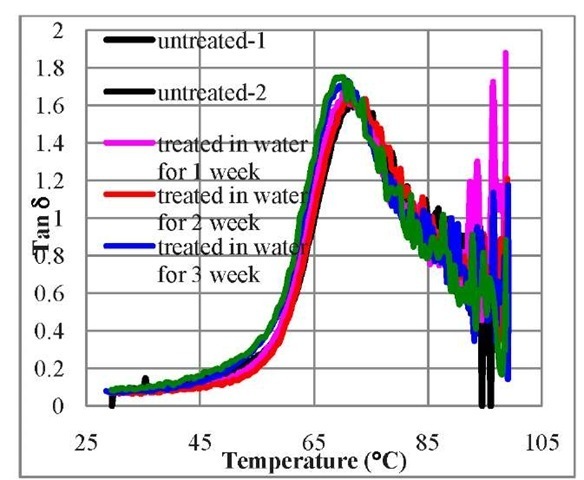

The behavior of tangent delta as a function of temperature due to immersion in water and diesel fuel solvents for 1- week and that of the untreated one has been shown in Fig. 10. From these curves we see that the temperature at the peak of the tangent delta, i.e., the glass transition temperature of the material decreases due to exposure to water and diesel fuel. We also observe that a greater decrease in the value of glass transition for the case of SMP degraded by diesel fuel in comparison to that of water. It is an indication that the molecular structure of the polymer has been greatly affected by diesel fuel at room temperature. We found that due to immersion in diesel fuel the tg decreases by 52.2% whereas the decrease of tg in water is only 1.3%.

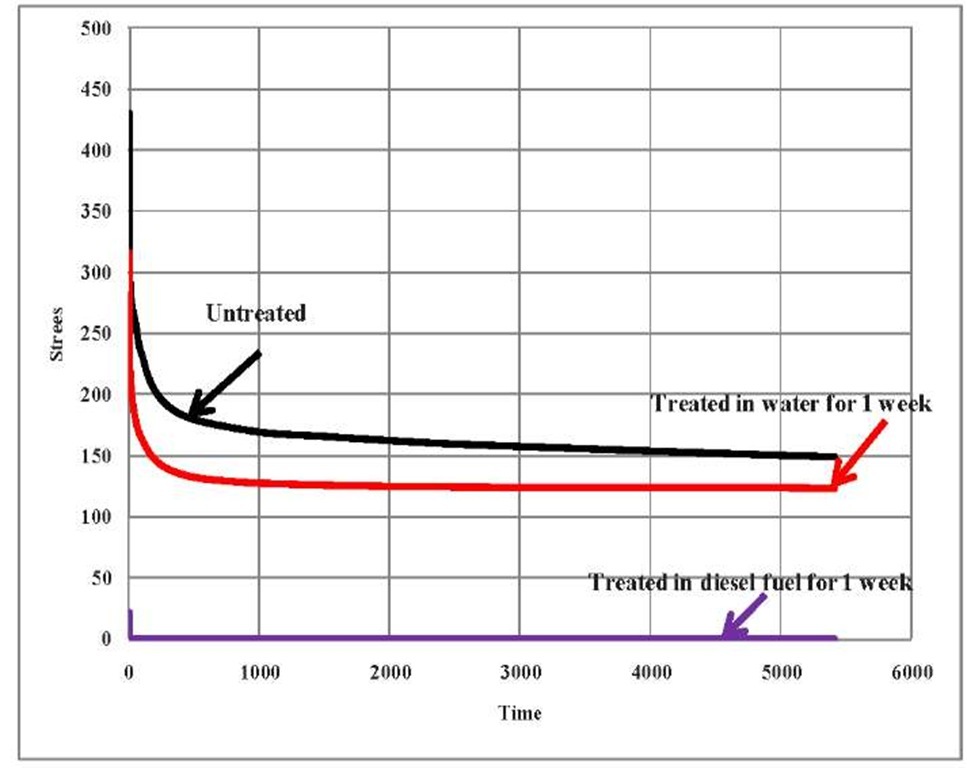

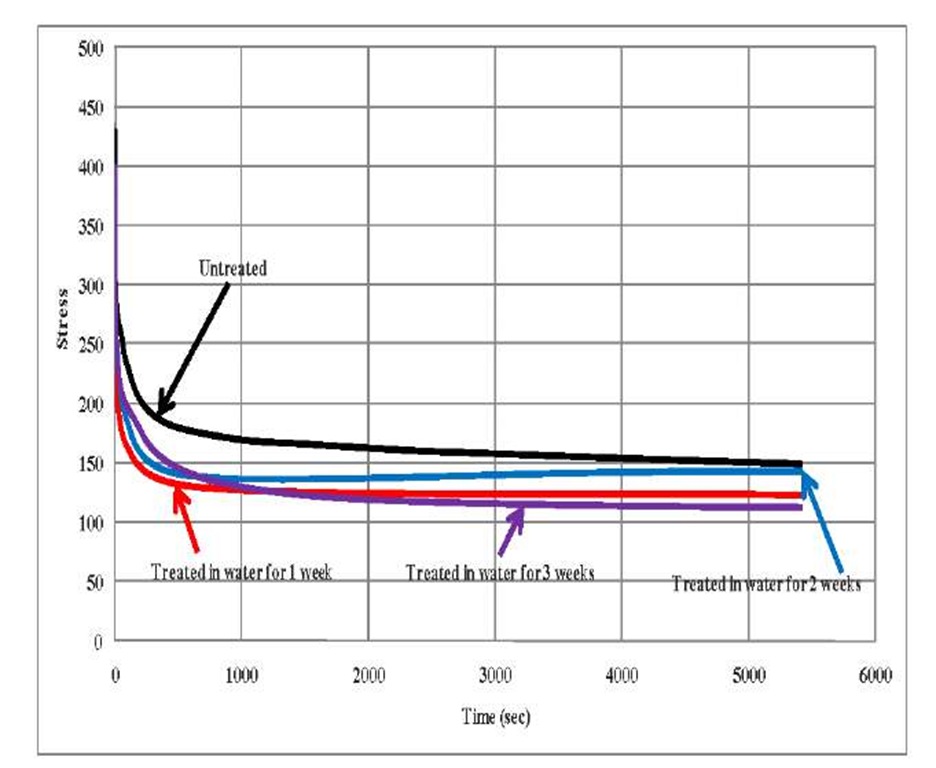

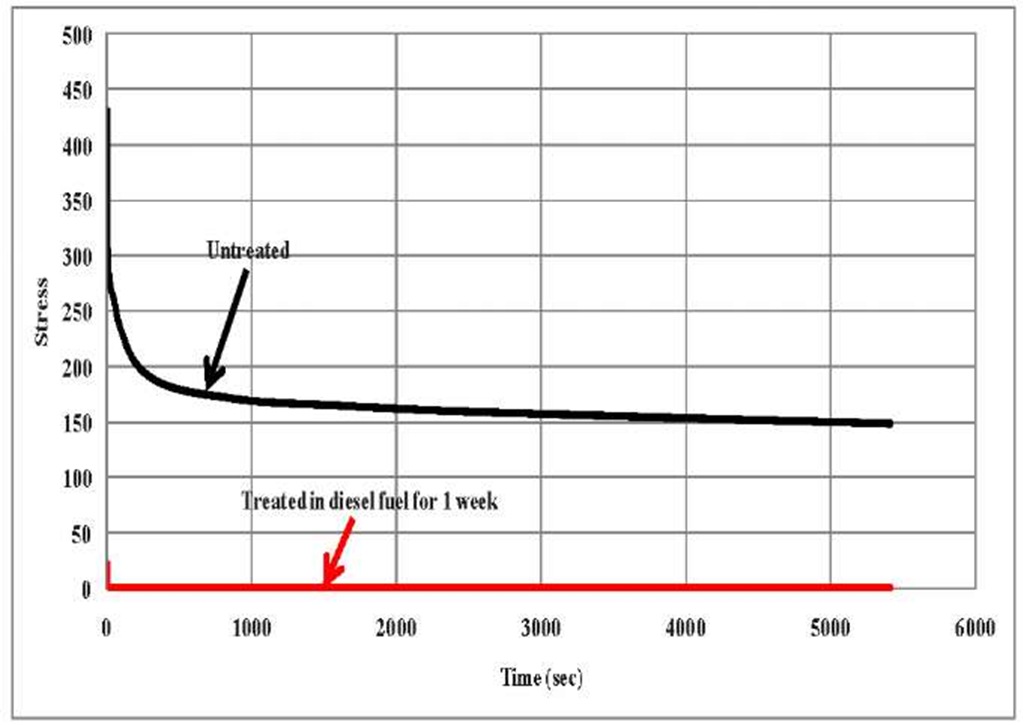

Normalized Force Decay Curves: When a constant strain is applied to a polymer at a constant temperature, the force required to maintain the strain decreases with time. This behavior is called stress relaxation. The stress relaxation, which depends upon the time scale, is usually the result of both physical and chemical processes. For short time and/or at room temperature, usually physical processes are responsible for the cause of stress relaxation. But in degradative environments or at higher temperature and/or for long times, chemical processes are more significant than physical processes. Figure 11 shows the decay of normalized force as a function of time for the untreated samples and the treated one with water and diesel fuel for one week. At the initial stage, the force required to maintain the deformation has decreased significantly. After the initial decrease of force, the force required to maintain the deformation remain almost constant with the passage of time and ultimately it reaches a plateau. The decay in force is the indicative of the onset of the physical and chemical relaxation processes within the SMP.

Fig. 11: Stress decay due to immersion in water & diesel

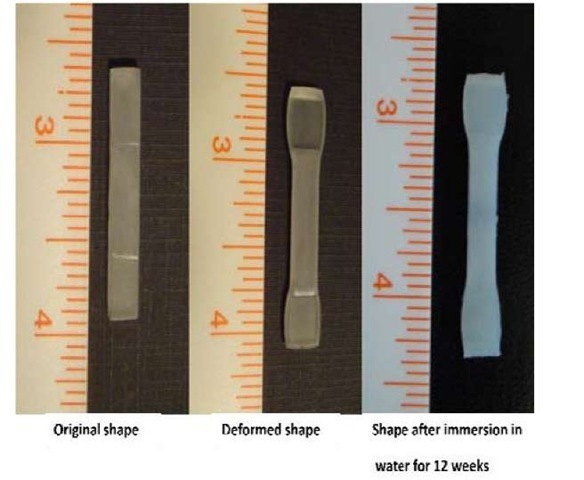

Fig. 12: SMP Shape memory phenomena due to water

It is also evident from Fig. 11 that the rate of decay in force is greater for the degraded ones. We can also see that due to immersion in diesel fuel the force required to maintain the deformation becomes almost zero. This is an indication of the change of state of the polymer from the glassy state to the rubbery state due to the immersion in diesel since; we know that in the rubbery state, the polymer is able to accommodate a large amount of deformation.

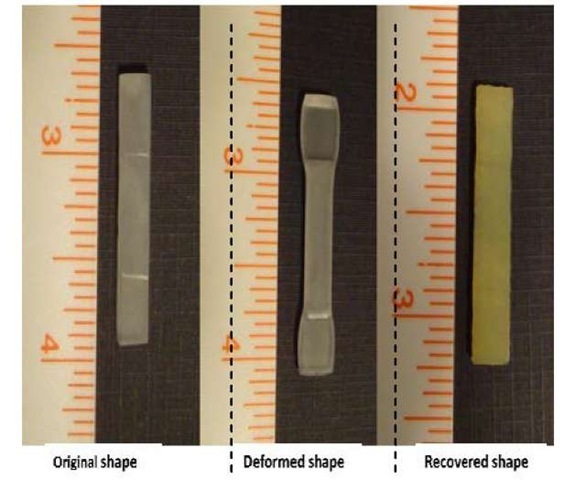

Effect of Degradation due to Water: After comparison of the degradation due to water and diesel fuel with the un-degraded one, now we investigate the effect of water SMP alone with the increase of immersion time. Shape Memory Phenomena The thermo-mechanical cycle to investigate the shape memory phenomena of SMP due to immersion in water has been shown in Fig. 12. The processes of the thermo-mechanical cycle have been described below:

(i) Initially, the SMP was in brick shape, which is its original shape. (ii) At this stage, the temperature of the SMP has been increased above the transition temperature and it has been deformed to a certain amount of tensile deformation (about 50%). After the application of deformation, the SMP has been cooled below the transition temperature while maintaining the constant load. At temperature below the transition temperature, the load has been removed. At the glassy state, the polymer is not able to reconfigure itself and the deformation has been locked- in. This shape is known as deformed or temporary shape. (iii) The deformed shape has been immersed in distilled water for up to 12 weeks to investigate the effect of water on the shape fixing capability of SMP. It has been shown that water does not have much effect on the shape fixing property of styrene based Veriflex- SMP. On the other hand, the color of SMP has been changed from transparent to opaque, ivory white (Fig. 12).

Change in Glass Transition Temperature

From Fig. 13 we see that water does not have significant change on the Tg of SMP. The percentage change in the transition temperature with respect to the untreated one after immersion for 4 weeks the change in transition temperature is only 4.66%. Change in Stress Relaxation

The change in stress relaxation due to immersion in water has been shown in Fig. 15. It is seen that due to immersion in water, the relaxation of force occurs at a faster rate in comparison to the untreated one.

Fig. 13: tan delta as a func. of temperature due to water

Fig. 14: Stress decay of Veriflex-SMP due to water

It has also been found that there is no difference in stress relaxation between 1 week and 3 weeks duration of immersion time. After duration of immersion in water for 3 weeks the polymer does not lose its capacity to withstand the load.

Fig.15: Phenomena of SMP due to diesel

Fig. 16: Change in transition temp. due to immersion in diesel

Effect of Diesel Fuel: Shape Memory Phenomena

Shape memory phenomena of SMP due to immersion in diesel fuel by going through the thermo-mechanical cycle which is shown in Fig. 15. The processes of the thermo-mechanical cycle have been described as: (i) Initially, the SMP was in brick shape, which is termed as its original shape; (ii) At this stage, the temperature of the SMP has been increased above the transition temperature and it has been deformed to a certain amount of deformation (about 50%). After the application of deformation, the SMP has been cooled below the transition temperature while maintaining the constant load. At temperature below the transition temperature, the load has been removed. At the glassy state, the polymer is not able to reconfigure itself and the deformation has been locked-in. This is known as deformed or temporary shape. The deformed shape has been immersed in diesel fuel to investigate the effect of diesel fuel on the shape fixing capability of SMP. It is observed that due to immersion in diesel at room temperature, Veriflex- SMP has been recovered its original shape after two weeks. The shape recovery of the SMP is almost 99%. It indicates that diesel fuel has a great influence on the shape fixing property of styrene based Veriflex- SMP. On the other hand, the color of SMP has been changed from transparent to opaque, yellowish (Fig. 15). Change in Transition Temperature

The effect of diesel fuel on the glass transition temperature, Tg SMP is shown in Fig. 16. It is seen that due to the immersion in diesel fuel for 1- week, the transition temperature of SMP has decreased to 34°C whereas due to immersion for 2 weeks, the transition temperature goes below the room temperature. The findings exactly verify the result obtained from thermo-mechanical cycle. It has also been observed that there is a considerable fluctuation in the behavior of tan 8 curve, which also indicates that the material goes into the rubbery state. As a result, the material is not able to withstand any amount of load and the fluctuations arrived from the frequency of the equipment.

Fig. 17: Stress decay of Veriflex- SMP due to diesel fuel

Change in Stress Relaxation

The effect of diesel fuel in stress relaxation of SMP is shown in Fig. 17. It is shown that due to the immersion in diesel fuel even for 1- week the stress relaxes drastically and ultimately it goes to zero. From the results, we can conclude that due to immersion in diesel fuel the SMP has gone to rubbery state since its load retention capacity goes to zero. We can also conclude that besides physical process, chemical process also occurs during the immersion period of SMP into diesel fuel, which breaks the crystalline portion of soft segment completely.

Discussion: Shape memory polymer’s hard and soft phases are incompatible. These phases are randomly distributed along the polymer chain forming a structure of separated micro-phases. The plasticization effects of water and diesel fuel also have a significant influence on the deterioration of property of SMP. Plasticizers are low molecular weight compound due to which the rigid polymeric materials become soften. They penetrate into the polymeric matrix and interrupt the chain-to-chain secondary bonding. As a result, the glass transition temperature of the material decreases. Usually, the Tg of a polymer, in contact with a plasticizer, depends on the Tg of the plasticizer. In this study, the Tg of the solvents used that is, water and diesel fuel, is much below in comparison to that of Veriflex-SMP, 62°C, and acts as a good plasticizer. As a result, the mechanical property of shape memory polymer has been degraded because of the plasticization effect of both solvent. We also see that diesel fuel acts as a better plasticizer for shape memory polymer in comparison to water since the load bearing capacity of shape memory polymer goes to almost zero due to immersion in diesel fuel.

CONCLUSIONS

The main aim of this research is to study the effects of degradation due to water and diesel fuel on the properties of styrene based Veriflex-SMP. The general key conclusions are summarized below:

(i) Veriflex- SMP immersed in water and diesel, showed the similar tendency in terms of degradation of property.

(ii) Due to immersion in diesel fuel, the appearance of Veriflex- SMP changes from transparent to opaque, yellowish one. On the other hand, due to immersion in water, the appearance of Veriflex- SMP changes to ivory white.

(iii) Due to degradation by diesel fuel significant reduction in glass transition temperature, Tg has been achieved; whereas the change due to degradation by water is less significant.

(iv) It is found that the Veriflex- SMP is able to recover the original shape from the deformed shape upon immersion in diesel fuel for 2- weeks; but the extent of recovery depends on the thickness of the sample. Thus, shape recovery can be triggered not only by applying energy but also without energy.

(v) Micro molecular solution absorbed in the Veriflex- SMP weakens the elasticity modulus, which causes a significant decrease in the Tg. As a result, the SMP is able to recover the original shape. It has been found that hydrogen bonding is mainly responsible for the changes in properties of Veriflex- SMP.