EXTENDED ABSTRACT

Magnesium alloys are unique materials because tensile twinning and de-twinning can be easily activated, which leads to rapid texture and hardening evolution [1]. Here we present a study of the mechanical response of a magnesium alloy (AZ31) when deformed under twinning dominated conditions, i.e. uniaxial compression along prior extrusion axis. In-situ neutron diffraction measurements were carried out using the SMARTS (Spectrometer for Materials Research at Temperature and Stress) instrument at LANSCE (Los Alamos Neutron Science Center) [2].

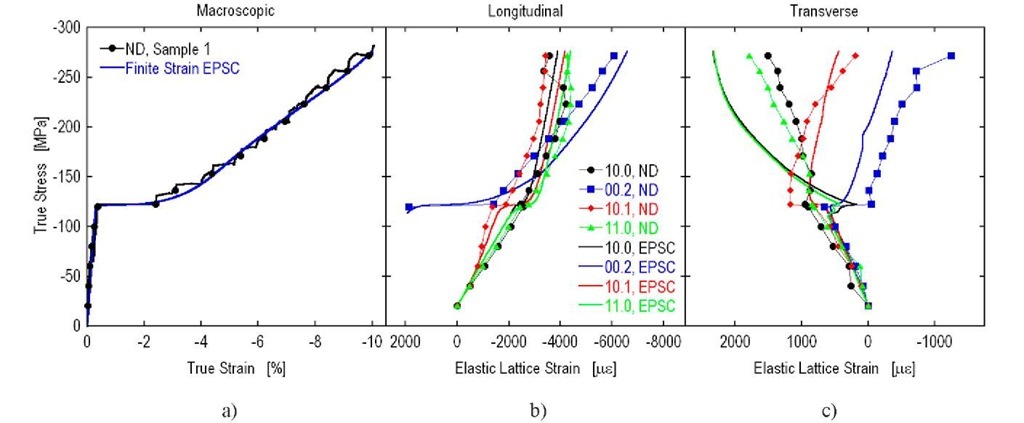

The neutron diffraction measurements provide both internal strain and texture information as a function of applied strain which have previously been used to validate predictions of the elastic-plastic self-consistent (EPSC) polycrystal deformation model [3,4]. In the present case it has lead to the development of a new twinning scheme [5] into the EPSC model that incorporates; i) twin activation, ii) twin reorientation (and the associated texture evolution), and iii) the specific stress relaxation associated with twinning. Although the texture development due to twinning is included, the underlying mechanics of the model are still based upon a small strain assumption, and thus it does not include texture development due to slip. The EPSC model including the new twinning scheme was able to predict the plateau in the macroscopic stress-strain curve and the atvoical internal strain development caused bv the nronounced twinnine as seen in Fieure 1.

Figure 1: Measured and calculated a) macroscopic stress-strain curve, b) longitudinal lattice strains, and c) transverse lattice strains. Symbols are measured data and lines are EPSC model predictions.

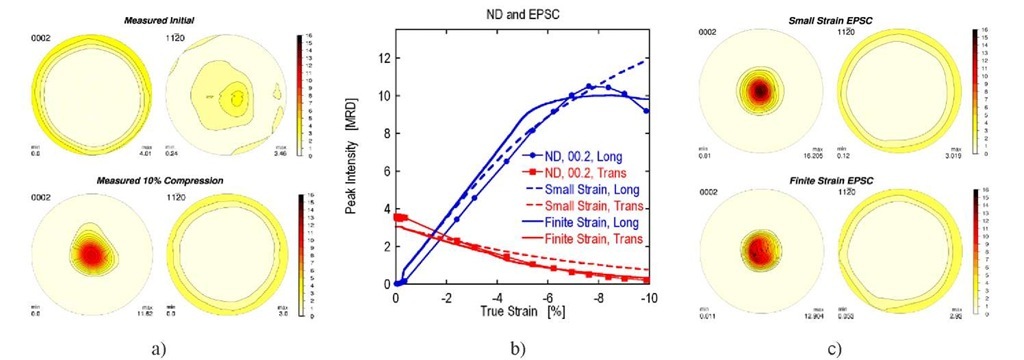

The prior extrusion process produced the so-called rod texture in the magnesium alloy that drastically favored tensile twinning in the following compression cycle by aligning the basal poles perpendicular to the extrusion axis as seen in Figure 2a). Initially there are no grains with their basal pole in the longitudinal direction, i.e. the loading direction and the prior extrusion axis, positioned at the center of the pole figures. Tensile twinning in magnesium alloys is associated with at 86.6 degree reorientation of the basal pole [6], which causes the basal poles to flip from the perimeter of the pole figure to the center, as seen in Figure 2a). This means that all the grains that contribute to the basal peak in the longitudinal direction are twins, and as seen in Figure 2b), they exhibit an initially tensile lattice strain even though the polycrystal is loaded into compression. Within the model, this ‘sense-reversal’ is captured by assuming that the twins immediately grow to a given size as they are nucleated [5]. This in turn causes a back stress in the twin and its parent grain that is responsible for the initial tensile lattice strain in the twins.

As mentioned above, almost all the grains are favorably oriented for twinning and, in fact, the twin volume fraction is approximately 70% after only 10% compression [5]. Hence, all the basal poles aligned with the compression axis after deformation as seen in Figure 2a). The rapid change in peak intensity during the deformation is shown in Figure 2b). The predicted intensity variation for the small strain EPSC model is also shown in Figure 2b). Although the model is able to predict the strong increase in the longitudinal basal pole intensity, it is clear that the decrease in the longitudinal basal pole intensity observed starting at about 8% strain is not reproduced.

Figure 2: a) measured initial and final basal and prism pole figures, b) measured and calculated basal peak intensity variation as a function of strain, and c) calculated final basal and prism pole figures.

A new finite strain EPSC model that includes the kinematics of large strains, rigid body rotations, texture evolution and grain shape evolution during deformation was introduced by Neil et al. [7]. The predictions of the finite strain EPSC model, which includes the texture development due to slip, are also shown in Figure 2b). It is clear that the finite strain EPSC model is reproducing the turn-over of the longitudinal basal pole intensity, which is caused by pyramidal slip in the twins. The pyramidal slip activity not only reduces the basal pole intensity at high strains, it also causes the spread in the center peak of the basal pole figure as evident in Figure 2c), and the maximum basal pole density predicted by the finite strain EPSC model is in better agreement with the measured data.

In conclusion, the complex internal strain state and rapid texture development during compressive loading of an extruded magnesium alloy caused by twinning has been investigated using neutron diffraction and EPSC modeling. The newly developed finite strain version of the EPSC model was able to reproduce the observed macroscopic and internal strain development as well as the texture development. It is obvious that even at modest degrees of deformation, materials with hexagonal close packed crystal structure exhibits strong texture development due to both twinning and slip activity, which significantly increases the