Abstract

American National Standards Institute (ANSI)/American Society of Heating and Refrigeration and Air-Conditioning Engineers, Inc. (ASHRAE) Standard 62.1-2004 is a short but often misunderstood document outlining ventilation requirements intended to provide acceptable indoor air quality (IAQ) for new buildings or those with major renovations. Because of the rate-based nature of both procedures allowed for compliance, this analysis focuses on the practical needs of reliable intake rate control and the risks of indirect controls. Design recommendations offered are intended to increase the potential for both predictable compliance and the flexibility to accommodate future changes while providing the greatest control reliability with the most energy-efficient methods.

INTRODUCTION

This is a summary of American Society of Heating and Refrigeration and Air-Conditioning Engineers, Inc. (ASHRAE) Standard 62.1-2004, ventilation for acceptable indoor air quality (IAQ) in Commercial, Institutional, Industrial, and High rise residential buildings,[1] as it impacts and is influenced by ventilation control requirements, methods, and equipment. Operational implementation of these requirements can have a sizeable influence on energy usage when applied improperly or incompletely. Operational precision and design reliability are essential for energy minimization when compliance with 62.1 and energy codes are simultaneous goals.

This is not a condensed version and this does not cover all requirements of the Standard. Designers are strongly encouraged to read the entire 19-page document (a total of 44 pages with appendices). The Standard cannot be understood or properly applied without considering the relationships and interdependencies of requirements of the document.

This American National Standards Institute (ANSI)-approved standard has been developed by a Standing Standards Project Committee (SSPC) of the ASHRAE under a ‘continuous maintenance’ protocol. At any point in time, the ‘official’ Standard is comprised of both the most recently published parent document and all current addenda. The latest parent document was republished earlier this year to combine 17 addenda that had been approved subsequent to the original release of the 62-2001 ‘parent’ document in January 2002. The result is a final version that is substantially different from the basic ventilation standard we have used since 1989.[1]

In 2003, the scope of the Standard officially changed and a separate ASHRAE committee was formed to address the specific needs of low-rise residential buildings. The existing Standard became known as 62.1 and the new residential standard became 62.2.

The promised 62.1 User’s Manual was recently published in December 2005. Work continues on a Guideline 19P, which is intended to provide design guidance for methods that exceed the minimum requirements of the Standard. Both of these supplemental documents should assist the designer and the facility operator in their understanding of and compliance with the Standard.

ANALYSIS AND RECOMMENDATIONS

Our discussion of Standard 62.1 will try to mimic the structure of the Standard, provide recommendations for compliance, and highlight methods and assumptions to avoid. Our objectives have determined the content.

The Standard’s “Purpose” and “Scope” are covered in Sections 1 and 2. To comply with the Standard, designers of mechanical ventilation systems are tasked to provide specific minimum rates of acceptable outdoor air to the breathing level of the occupied structures. In doing so, an acceptable indoor environment may be achieved providing improved occupant productivity and health. The procedures allowed for compliance with our national standard on ventilation are prescriptive or performance-based. Their selection and application should be evaluated for IAQ risk by the design practitioner.

Definitions

Section 3 addresses the definition of terms used within the Standard. Noteworthy is the Standard’s definition of “acceptable IAQ,” which is defined as:

… air in which there are no known contaminants at harmful concentrations as determined by cognizant authorities and with which a substantial majority (80% or more) of the people exposed do not express dissatisfaction.[1]

This means that 62.1, like all ASHRAE Standards, assumes that one out of five occupants (20%) might not be satisfied with the results of compliance and might express dissatisfaction with the IAQ, even if the Standard is followed perfectly. Many sources have concluded that the majority of Heating Ventilation Air Conditioning (HVAC) systems designed in the United States do not meet the minimum ventilation rates prescribed during operation. In which case, the actual occupant dissatisfaction level is exponentially greater in practice.[2] It is not uncommon for rates to fall below levels that result in occupant dissatisfaction significantly greater than 50%. Many systems cannot meet the minimum airflow requirements at the occupied space during operation because of design choices and equipment limitations or due to the dynamic nature of mechanical ventilation systems and the constant external forces acting on the building envelope.

The impacts from these continuously changing external conditions are not limited to variable air volume (VAV) systems.[2] Outdoor airflow rates will also vary for systems that provide a constant volume of supply air (CAV) to the conditioned space, as a result of:

1. Changes in wind or stack conditions on the intake [3] system,

2. Changes in filter loading, or

3. Changes in airflow requirements during an economizer cycle.

The lack of specific guidelines to overcome the effect of changing system dynamics on ventilation rates and air distribution for today’s HVAC systems are partially to blame for many design deficiencies observed.

Unlike thermal comfort, the effect of IAQ is difficult to measure (The work item that caused the most controversy was an attempt to standardise design criteria for the indoor environment). The criteria developed in the process have been published as a CEN Technical Report CR 1752. It specifies the levels of temperature, air velocity, noise, and ventilation for occupied spaces. Values are given for three categories of environmental quality: A—a high level of expectation, B—a medium level and C—a moderate level.

Supporting information is given on the derivations of the specified values of the parameters as well as to enable alternatives, such as different clothing levels, to be accommodated in the design assumptions. The most debatable section is on IAQ. Here, prominence is given to the evaluation of the required ventilation rate for comfort based on perceived air quality, the method developed by Professor Fanger and his colleagues in Denmark. While some data is presented, it is acknowledged that more research is needed to provide reliable information on pollution loads from materials and on the additive effects of emissions from multiple sources

Outdoor Air Quality

Section 4 of the Standard describes a three-step process to evaluate outdoor air for acceptability. One of those steps requires examination of both the regional and the local air quality by the building owner. The section also specifies the documentation required to support the conclusions of this preliminary review.

If the outdoor air quality is found to be unsuitable per Section 4, then treatment may be required as indicated in Section 6.2.1. Outdoor air treatment involves the removal of the particulates and gases encountered that are in excess of the minimum standards cited by cognizant authorities in Section 4.1.

Systems and Equipment

Section 5 specifies the minimum systems and equipment required under Standard 62.1. Section 5.4 states:

Mechanical ventilation systems shall include controls, manual or automatic, that enable the fan system to operate whenever the spaces served are occupied. The system shall be designed to maintain the minimum outdoor airflow as required by Section 6 under any load condition. Note: VAV systems with fixed outdoor air damper positions must comply with this requirement at minimum supply airflow.[1]

The Standard recognizes that changes in mixed air plenum pressure, up to 0.5 in. WG [125 Pa] variation on VAV systems, can significantly influence outdoor air intake flow rates. However, it neglects the significant influence of external pressure variations on all systems that result from changes in wind and stack pressures, which often exceeds 0.5 in. WG [125 Pa]. Therefore, providing the minimum outdoor airflow defined in Section 6 ‘effectively’ requires a dynamic control alternative for compliance—possibly the use of permanent devices capable of maintaining outdoor airflow rates.

Not mentioning airflow measurement is analogous to ignoring the requirement for temperature measuring devices to maintain continuous temperature control. Because many systems, especially VAV, have thermal load requirements that differ from their ventilation needs, the requirements of this section can be more sustainable if the multispace Eqs. 6-1 to 6-8 are calculated for the design supply flows to individual zones using the minimum outdoor air requirements to each zone. In order to achieve the industry “standard of care” in professional HVAC design, the mechanical engineer is required to determine which zones may become ‘critical’ and that the worst ‘critical zone’ is at its minimum supply airflow. Even with the average reduction potentials due to the new ventilation rate (Table 6-1), this could still impose a severe energy penalty to many VAV system designs.

it is necessary to maintaiBecause of the requirements set forth in the Standard for compliance “under any load condition,” n a constant rate of outdoor airflow in dynamic systems. Logically, Section 5 should require continuous airflow measurement at the intake of all air-handling units with automatic controls that function to provide a building or space with a constant rate of outdoor air, regardless of the system size or type. Doing so would alleviate several practical issues, clarify application and compliance questions in Section 6.2.7, Dynamic Reset; Section 7.2.2, Air Balancing; and Section 8.4.1.8, Outdoor Airflow Verification. A continuous measurement requirement was explicitly stated in the draft Standard 62-89R before Standard 62 became politicized, which was much more complicated and vague to the point of confusion.

American Society of Heating and Refrigeration and Air-Conditioning Engineer’s new 62.1 User’s Manual provides more insight into the appropriate, if not encouraged, use of permanent instrumentation for continuous measurement, by explaining further:

For VAV systems that can operate under a wide range of operating conditions, the system must be designed to provide the minimum outdoor air rates under all reasonably anticipated operating conditions (see Ref. 5, pp. 6-33).

To comply [with Std. 62.1], most VAV systems will need to be designed with outdoor airflow sensors and modulating dampers or injection fans (see Ref. 5, pp. 5-10). In most cases, an active control system must be provided at the air intake and sometimes at the zone level to ensure minimum rates are maintained… Note that a fixed-speed, outdoor air fan without control devices will not maintain rates within the required accuracy (see Ref. 5, pp. 5-11).

We are encouraged to use direct measurement feedback for continuous control on all VAV designs, even those using a powered outdoor air system (i.e., injection fan, heat recovery ventilators (HRV)/energy recovery ventilators (ERV), smaller dedicated outdoor air systems (DOAS), etc.). Although not contained in the society’s ‘minimum’ standard, ASHRAE is highlighting the potential source of problems and the more obvious means to avoid them.

We believe and recommend that Section 5 of the Standard should encourage the use of airflow measuring devices in the supply air to critical zones of VAV systems, allowing not only for improved operating savings for continuous verification of compliance and as a diagnostic tool but also to reset intake rates based on input from the continuous calculation of the multispace equations defined in Section 6.2. Although this may sound impractical to some designers, the technology is available and surprisingly cost effective, especially when considering the potential benefits in occupant productivity and health, reduced potential liability, and the energy savings available.

Pressurization and Mold

Addendum 62x (62-2001) was approved in 2004 for inclusion with the Standard, but problems identified immediately after publication generated addendum 62.1a (Table 1), which was just published in a supplement to the 2004 document during this writing (May 2006).

The proposed addendum only addresses positive pressure during periods of dehumidification.

Moisture is a prerequisite for mold and fungal growth and the condition should be avoided. Whenever the temperature of a building envelope is lower than the dew point of air migrating across it, there will be condensation and the potential for mold. Costs for design improvements or preventive actions prior to mold conditions can range from an additional $1.50 to $15/ft2 [$16-$161/m2]. Costs for mold remediation and repair can range from $30 to $65/ ft2 [$323-$700/m2][6]. That effectively equals a penalty for inaction ranging from 4 to 20 times that of the cost for prevention.

The 62.1 User’s Manual also comments on pressure effects and ‘pressurization flow.’

Positive pressure in hot, humid climates can also reduce interstitial moisture and resultant fungal microbial growth.

5.10 Dehumidification Systems. Mechanical air-conditioning systems with dehumidification capability shall be designed to comply with the following:

5.10.1 Relative Humidity. Occupied space relative humidity shall be designed to be limited to 65% or less at either of the two following design conditions:1) at the peak outdoor dew point design conditions and at the peak indoor design latent load, or when system performance is analyzed with outdoor air at the dehumidification design condition (that is, design dew point and mean coincident dry-bulb temperature) and with the space interior loads (both sensible and latent) at cooling design values and space solar loads at zero.

Note: System configuration and/or climatic conditions may adequately limit space relative humidity at these conditions without additional humidity-control devices. The specified conditions challenge the system dehumidification performance with high outdoor latent load and low space sensible heat ratio. Exception: Spaces where process or occupancy requirements dictate higher humidity conditions, such as kitchens, hot tub rooms that contain heated standing water, refrigerated or frozen storage rooms and ice rinks, and/or spaces designed and constructed to manage moisture, such as shower rooms, pools and spas.

5.10.2 Exfiltration. For a building, the design minimum outdoor air intake shall be greater than the design maximum exhaust airflow when the mechanical airconditioning systems are dehumidifying.

Exception: Where excess exhaust is required by process considerations and approved by the authority having jurisdiction, such as in certain industrial facilities.

Note: Although individual zones within the building may be neutral or negative with respect to outdoors or to other zones, net positive mechanical intake airflow for the building as a whole reduces infiltration of untreated outdoor air. [1I

Stack and wind effects can cause large regions, such as entire levels or facades, to be negatively pressurized.[6]

A building that is excessively pressurized may cause damage to the structural integrity of the building envelope.[6]

Noting the proliferation of mold in buildings, the ASHRAE board issued Minimizing Indoor Mold Through Management of Moisture in Building Systems in June 2005, stating that sound moisture management should take precedence over energy cost savings.[7] This Position Paper outlines recommendations for the management of moisture in buildings by describing issues related to the topic and highlighting resources available through the society. This policy statement will filter through the society’s organization and eventually impact technical programs, research, and standards.

Some of their recommendations for proper moisture management include:

• Building and system design, operation, and maintenance provide for drying of surfaces and materials prone to moisture accumulation under normal operating conditions.

• Mechanical system design should properly address ventilation air.

• The sequence of operation for the HVAC system should contain appropriate provisions to manage humidity, control pressurization, and monitor critical conditions.1-7-1

The flaw of ASHRAE’s position is in ignoring the potential for high humidity alone to provide sufficient moisture content for mold growth. Studies have shown that in temperatures between 30 and 86°F [— 1.1°C-30°C] with a minimum relative humidity of 70% RH (noncondensing infiltration), mold growth has appeared on plasterboard, brick, and concrete within 3 days. At 65.3°F [18.5°C] (with adequate RH and “inadequate” substrate), mold grows on building materials after 6 h. It was shown to take only 1 h to grow with “adequate” substrate.[2'8]

Part of the solution to preventing infiltration of unfiltered and unconditioned humid air appears to be simple. In 1996, the Florida Solar Energy Center first published a case study which identified that an extremely small negative pressure differential created conditions that lead to mold problems in a small commercial building. This was later supported by a 2002 ASHRAE journal article whose recommendations indicated that differential pressures as low as + 0.004-+ 0.008 in. WG [1-2 Pa] will prevent moisture infiltration problems.[9] This counter-flow overcomes most of the natural pressures that power moisture migration, namely vapor, temperature (stack), and wind pressures. Those periods when pressurization flow is insufficient to counter infiltration are generally limited in duration. Thereafter, the flow of air to the direction of higher dew point temperature can remove any residual moisture in the wall cavity.

Control precision and control stability should be key objectives when energy usage is to be minimized and dynamic control of space pressurization is used.

‘Building pressure’ is accomplished by creating a pressurization flow. Anything that changes the pressurization flow will result in fluctuations in building pressure. The pressurization flow is generally influenced by the HVAC system by controlling the volumetric differential of either the intake/relief air or the supply/ return air. Heating ventilation air conditioning system control strategies that ignore these relationships or poorly implement them are widely known to have inherent pressurization problems.

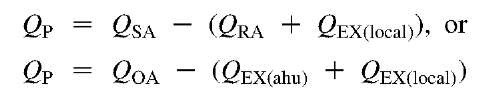

Regardless of the system design, an effective method for maintaining pressurization flow is to monitor and control these airflow differentials. Typically, pressurization airflow (Qp) is maintained at a fixed differential by an independent control loop; independent of the supply airflow rate required for temperature control, which uses a separate control loop. The airflow relationship is as follows:

where QP, pressurization airflow; Qsa, supply airflow; QRA, return airflow; 2EX(ahu> exhaust/relief at AHU; QEX(iocai), sum of local exhausts for zones served by ahu.[2]

The Standard must eventually address wind and stack effect and provide design guidelines that reflect conditions that influence buildings in their normal, native environment. In addition, increased humidity combined with wind-and stack-driven infiltration during periods when the ventilation system is not operating may be a significant factor influencing mold and fungal growth, e.g., offices and schools during closures. Designers and building operators should consider a limited night setback mode with provisions for humidity and pressurization flow controls. Such provisions would also tend to compensate for the building-generated contaminants by supplying a base ventilation rate, sufficient for minimal pressurization flow.

There is potential for condensation to occur under a positive pressure environment during periods of humidification in cold climates because the dew point of the air within a building could potentially be greater than the temperature of the building envelope. Maintaining a building at ‘net neutral’ pressure would be more appropriate under these conditions. ‘Net neutral’ control requires even more precise instrumentation and measurement directionality.

The widespread use of ERV in some geographic areas has decreased the amount of outdoor air available to pressurize a building and decreased the margin of error in control to maintain it. Although outdoor airflow rates into many buildings have increased with the use of ERVs, there is a strong potential for an increase in building pressurization problems which could lead to increased mold and fungal growth. Designers should exercise caution when implementing strategies that rely on ERV units for outdoor air and result in building design pressures that are close to net neutral. Wind, stack, and filter loading can easily result in depressurized buildings and increased condensation within the hidden cavities of the building envelope.[2]

Procedures

Section 6, Procedures, is the heart of the Standard. For compliance, designers must claim using either the ventilation rate procedure (VRP) or the indoor air quality procedure (IAQP) to determine the minimum dilution ventilation rate required for their design. Designers and operators cannot selectively ignore the parts they do not like. The entire procedure must apply. Parts from each procedure cannot be combined to achieve ventilation rates lower than those determined by the VRP alone. Great care should be given to the selection between these procedures.

The VRP, as defined in Section 6.1.1, “is a prescriptive procedure in which outdoor air intake rates are determined based on space type/application, occupancy level and floor area.”[1] The key phrase is “prescriptive procedure in which outdoor air intake rates are determined.” Very simply, this implies the need for some form of airflow measurement.

The alternative, IAQP in Section 6.1.2, “is a design procedure in which outdoor air intake rates and other system design parameters are based on an analysis of contaminant sources, contaminant concentration targets and perceived acceptability targets.”[1] Any analysis of this procedure quickly reveals the clear discussion of airflow rate requirements based on varying contaminant levels.

Ventilation Rate Procedure

The VRP detailed in Section 6.2 is rate based. There is no question about this. In fact, the entire Standard is rate based, including the IAQP, which only provides the means to calculate allowable reductions in the design ventilation rate from those in Table 6-1.The explicit statement to this effect was removed last year in an effort to render the language in the Standard more ‘code enforceable.’ Designers claiming compliance with the VRP must be able to document and substantiate that minimum intake rates are maintained during operation and “under all load conditions.” They are not just ‘capable of’ maintaining—they are ‘maintained’ at no less than the higher of either code-required levels or those indicated by Table 6-1, and calculations in Section 6.2 of the Standard.

Once the outdoor air is determined to be acceptable or has been treated for use indoors, we can begin to determine how much is needed under our specific design situation. We can simplify the relationships and view the VRP with the aid of this partial flow chart from the new 62.1 User’s Manual (Fig. 1).

First, we must calculate outdoor airflow requirements for the zone (Voz), as detailed in Sections 6.2.2.1-6.2.2.3, which can be summarized with their corresponding equations and reference numbers below:

Calculate breathing — zone outdoor airflow:

Fig. 1 Ventilation rate procedure (VRP) flow chart.

Determine zone air distribution effectiveness: Ez = Table 6-2

Calculate zone outdoor airflow at diffusers:

Then, determine the outdoor airflow requirements for the system (Vot) and calculate minimum outdoor air intake flow. We are given three general system types to choose from:

In Multizone recirculation systems (Vou and EY), the variables needed to solve for Vot are determined in Sections 6.2.5.1-6.2.5.4 and summarized below, but will be examined in more detail later.

Calculate the Zone primary outdoor air fraction:

temperature balance, mass balance, steady-state CO2 concentration, etc.). However, the uncertainty of indirect techniques introduces a significant level of risk (see Ref. 5, pp. 5-12).[2,10] The designer, facility owner, and occupants should carefully consider the method employed prior to implementation of any CO2-based demand controlled ventilation (DCV) scheme as the sole method of intake rate determination.

The new VRP in Section 6.2 recognizes the magnitude of building-generated pollutants and subsequently added the “building component” in the zone ventilation equation. Table 6-1 and the accompanying notes specify outdoor air requirements for specific applications. Eq. 1 (Table 2) is now based on the combination of ventilation rates per person (as CFM/p) PLUS ventilation rates per floor area (as CFM/ft2). Therefore, systems that meet these requirements:

One subtle change in the updated Standard includes the characterization, usage, and definition of “breathing zone.” Plus, separate components are included to address both occupant and building-generated contaminants. Rates are no longer determined solely on occupancy “per person.”

Total intake rates at the air handler can be directly determined with handheld instruments used in accordance with prescribed standards or by using an appropriate and permanently installed airflow measuring device. Total intake rates may be indirectly estimated by several other means (i.e., supply/return differential calculation, can claim that their ventilation system complies with the Standard through the VRP.

1. The minimum requirements of Table 6-1 combined with

2. The calculated volume of outdoor air required by Section 6.2 and

3. The outdoor air quality requirements set forth in Section 4

4. While “under any load condition,”

Under ideal and very specific conditions, CO2 levels can only reflect the rate that outdoor air enters the building on a per person basis, through any and all openings. Therefore, CO2-based DCV with single ‘ppm’ set point control cannot be implemented under the new requirements of Standard 62.1 unless it is applied with excessive conservatism and the accompanying increase in energy usage. Otherwise, it will invariably underventilate spaces, overventilate spaces, or require that the Standard be rewritten or interpreted in such a way to allow the potentially large airflow errors that will result from using CO2 sensor input (Table 3).

6.2.2.1 Breathing Zone Outdoor Airflow. The design outdoor airflow required in the breathing zone of the occupiable space or spaces in a zone, i.e., the breathing zone outdoor airflow (Vbz), shall be determined in accordance with Equation 6-1.

where:

Az = zone floor area: the net occupiable floor area of the zone m2, (ft2).

Pz = zone population: the largest number of people expected to occupy the zone during typical usage. If the number of people expected to occupy the zone fluctuates, Pz may be estimated based on averaging approaches described in Section 6.2.6.2. Note: If Pz cannot be accurately predicted during design, it shall be an estimated value based on the zone floor area and the default occupant density listed in Table 6-1.

Rp = outdoor airflow rate required per person as determined from Table 6-1. Note: These values are based on adapted occupants.

Ra = outdoor airflow rate required per unit area as determined from Table 6-1. Note: Equation 6-1 is the means of accounting for people-related sources and area-related sources for determining the outdoor air required at the breathing zone. The use of Equation 6-1 in the context of this standard does not necessarily imply that simple addition of sources can be applied to any other aspect of indoor air quality.[1]

The new 62.1 User’s Manual is really very well done. It will improve the readers’ understanding of the Standard and provide needed design guidance with its examples. However, it does make a number of assertions that will leave you scratching your head.

This is a real problem for practitioners. The document intentionally leaves the details of how to address the ‘building component’ of the total rate required to the imagination of the designer wanting to use CO2. It should advise the reader of at least the most correct method to use.

It also appears that the fundamental basis for the Standard, maintaining minimum intake rates, has been transformed by the topic to the User’s Manual to become the maintenance of “an acceptable bioeffluent concentration.”1-6-1 ASHRAE has published interpretations to the Standard, insisting that sensing for a single contaminant ignores potentially high levels of all other contaminants. To do so is to ignore all other design, environmental, or operational factors that impact the actual variable to be controlled—ventilation rates. Sensing an “indicator” of proper ventilation and using it for direct control raises liability issues and ignores what is really occurring at the outdoor air intake.

Indirect measurements for control typically carry such a large degree of uncertainty that one can never be secure that the controlled variable (ventilation rates) will not drop below or substantially exceed the mandated minimums under operating conditions.

There is too much risk. Compliance with the intelligent motor control (IMC) using CO2 is questionable. Compliance with ASHRAE 62.1 is questionable. Why use it when there are other more reliable methods available to accomplish the same function or similar results?

Multispace ‘Equations’ Become a Design ‘Procedure’

Once the breathing zone outdoor air requirement is determined, the Standard requires an adjustment based on the distribution system’s efficiency and effectiveness. This makes complete sense because the air must reach the breathing zone to be effective.

These methods produce significantly different results. The more precise method is contained as might be expected, it is more involved. The Table’s conciseness requires it to be more conservative and therefore not as efficient in many situations.

For each multiple zone recirculating system (VAV or CAV), the primary outdoor airflow fraction must be calculated for all zones that may become ‘critical’ (only one zone can be critical on CAV systems). The “critical zone” is defined as the zone that has the highest percentage of outdoor air required in the primary air stream. When analyzing a VAV system dynamically, treat it as a CAV system.

As an example, if the supply air distribution system is located close to the return air, a short circuit is generally created. The Standard requires designers to use a zone air distribution effectiveness (Ev) of 0.5, which essentially doubles the amount of outdoor air required. In contrast to this example, a system with a ceiling supply and a ceiling return has a zone distribution effectiveness of 1.0 during cooling and 0.8 during heating. Therefore, the outdoor air setpoint must be reset seasonally or the more conservative factor used.

Systems that provide a variable supply of air volume to the conditioned space are influenced by everything previously discussed. In addition, outdoor airflow rates will vary as a result of changes in mixed air plenum pressure. If the design did not assume the worst-case scenario when the outdoor airflow rate for the air handler was determined, outdoor airflow rates on VAV systems may need to be reset based on calculations of the multispace equations (Eqs. 6-5 to 6-8, defined in Table 4), in order to avoid potentially excessive over ventilation and the associated energy penalty.

Advanced VAV control strategies can satisfy the requirements of Sections 6.2.5.1-6.2.5.4 dynamically and therefore more efficiently than static strategies. This can be accomplished by automatically determining the critical zone fraction to continuously calculate the corrected fraction of outdoor air. The calculation requires that the total supply airflow rate be continuously measured and that the airflow rate of the critical zones is measured with permanent airflow measuring devices capable of accurate measurement.

Airflow sensors provided with VAV boxes should not be used for these calculations. Although the original equipment manufacturer (OEM) devices may be adequate in modulating a terminal box for thermal comfort, the combination of typically poor inlet conditions, low quality airflow pickups, and low cost pressure sensors in the direct digital control (DDC) controller will not result in the measurement accuracy necessary for proper calculation of Eqs. 6-1 and 6-5 to 6-8. Conservative mathematical modeling has demonstrated that typical VAV box measurement performance

Table 4 Section 6.2.5

6.2.5 Multiple-Zone Recirculating Systems.When one air handler supplies a mixture of outdoor air and recirculated return air to more than one zone, the outdoor air intake flow (Vot) shall be determined in accordance with section 6.2.5.1 through 6.2.5.4 [Equations 6-5 through 6-8].

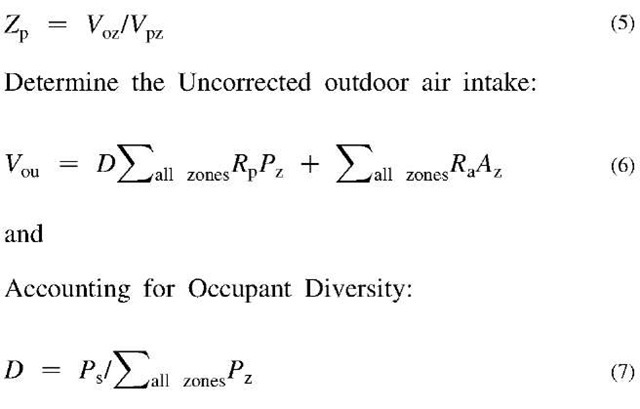

6.2.5.1 Primary Outdoor Air Fraction. When Table 6-3 is used to determine system ventilation efficiency, the zone primary outdoor air fraction (Zp) shall be determined in accordance with Equation 6-5.

where Vpzis the zone primary airflow, i.e., the primary airflow to the zone from the air handler including outdoor air and recirculated return air.

Note: For VAV systems, Vpzis the minimum expected primary airflow for design purposes.

6.2.5.2 System Ventilation Efficiency. The system ventilation efficiency (Ev) shall be determined using Table 6-3.

The occupant diversity, D, may be used to account for variations in occupancy within the zones served by the system. The occupancy diversity is defined as:

6.2.5.3 Uncorrected Outdoor Air Intake. The design uncorrected outdoor air intake (Vou) shall be determined in accordance with Equation 6-6.

where the system population (Ps) is the total population in the area served by the system.

Alternative methods may be used to account for population diversity when calculating Vou, provided that the resulting value is no less than that determined by Equation 6-6. Note: The uncorrected outdoor air intake (Vou) is adjusted for diversity but uncorrected for ventilation efficiency.

6.2.5.4 Outdoor Air Intake. The design outdoor air intake flow{ Vot) shall be determined in accordance with Equation 6-8.

can be statistically exceeded by boxes without a measurement device.[2] Accurate airflow measuring devices having a total installed accuracy better than 5% of reading at maximum system turndown should be installed in the supply ducts for critical zones.

Increased precision allows terminal box selection for optimum energy performance as well as improved sound performance. Accordingly, a recently proposed ASHRAE TC1.4 Research Work Statement claims that using VAV box sensors and controllers allowing “a 20% minimum airflow setpoint can save $0.30/ft2-yr. [in energy costs]. Multiplied across the millions [billions?] of square feet of commercial space served by VAV boxes, the potential economic, health and productivity benefits are significant.”

The results from these multispace equations can provide wide variations in outdoor airflow requirements in some systems. Increasing the critical zone supply flow while using reheat can reduce total outdoor airflow rates and overall energy usage. This method has been simulated using the multispace equation from Standard 62-2001 at Penn State University, with published results showing greater energy efficiency than the same system supplying the maximum, worst-case Vot continuously. The basic variables, relationships, and end results should be the same using the VRP of Standard 62.1.

Then, the VRP continues and provides us with additional options to help make the design more specific to the designer’s needs and to the demands of the situation. You may…

• Design using the short-term “averaged” population rather than the peak—Table 5 (9)

• Operate (and dynamically reset requirements) using “current” population data—Table 6, “DCV”

The peak population value may be used as the design value for Pz. Alternatively, time-averaged population determined as described in Section 6.2.6.2 may be used to determine Pz.

Outdoor airflow rates can also be reduced if the critical zones have variable occupancy or other unpredictably variable (dynamic) conditions. Changes in occupancy (or ventilation ‘demand’) can be detected in many ways, as indicated in the ‘note’ below. Therefore, DCV systems functioning to dynamically adjust the outdoor air intake setpoint should not be limited to CO2 measurement input alone.

Section 6.2.7 (Table 6) on Dynamic Reset addresses conditions when the ventilation control system…

6.2.6 Design for Varying Operating Conditions.

6.2.6.1 Variable Load Conditions. Ventilation systems shall be designed to be capable of providing the required ventilation rates in the breathing zone whenever the zones served by the system are occupied, including all full- and part-load conditions.[1]

Table 6 Section 6.2.7

“.. .may be designed to reset the design outdoor air intake flow (Vot) and/or space or zone airflow as operating conditions change. These conditions include but are not limited to:

1. Variations in occupancy or ventilation airflow in one or more individual zones for which

ventilation airflow requirements will be reset.

Note: Examples of measures for estimating such variations include: occupancy scheduled by time-of-day, a direct count of occupants, or an estimate of occupancy or ventilation rate per person using occupancy sensors such as those based on indoor CO2 concentrations.

2. Variations in the efficiency with which outdoor air is distributed to the occupants under different ventilation system airflows and temperatures.

3. A higher fraction of outdoor air in the air supply due to intake of additional outdoor air for free cooling or exhaust air makeup.[1]

There is no indication in the Standard of how to implement Dynamic Reset with CO2, which was left to be addressed by the User’s Manual. The User’s Manual included an topic intended to address the continuing questions by users and designers: “How can we apply CO2 measurements to DCV and comply with the VRP of Standard 62.1?” To this end, the topic hedged sufficiently to avoid answering this question directly, underscoring the potential problems in applying DCV and simultaneously employing outdoor airflow measurement.

This section (Section 6.2.7), independent of the User’s Manual, would lead one to believe that CO2 is a method of “counting” and not an input to be used for direct ventilation control. Any counting method can be used to reset a flow rate established and controlled by some other measurement means. Intake rates should not be indirectly determined by the “counting” method.

Indoor Air Quality Procedure

Section 6.3 Indoor Air Quality Procedure begins…

The Indoor Air Quality Procedure is a performance-based design approach in which the building and its ventilation system are designed to maintain the concentrations of specific contaminants at or below certain limits identified during the building design and to achieve the design target level of perceived IAQ acceptability by building occupants and/or visitors… ,[1]

The concept of providing “performance-based” solutions is desirable in principle. However, there are numerous risks associated with both the quantitative and subjective evaluations provided within the IAQ procedure that every designer should understand.

Because there are numerous contaminants that either will not be detected or for which “definite limits have not been set,” this portion of the procedure has significant risks associated with it. It is unlikely that all contaminants of concern will be evaluated or reduced to acceptable levels. It is also not practical to measure all potential contaminants, and in some cases, such as with fungus or mold, measurement may not be possible.

However, the concept of controlling the source of the contaminants makes perfect sense and is, in our opinion, more properly utilized under design approach Table 8 (d).

Because airflow rates are typically reduced in the IAQP, the measurement and control of intake rates are even more critical, especially on systems where the thermal load change is independent of the occupants and their activities. In addition, caution should be exercised when reducing outdoor airflow rates because it is also required to maintain proper building pressure, helps to minimize energy use, improves comfort control, and prevents mold growth within wall cavities.

Design Documentation Procedures

Section 6.4, Design Documentation Procedures, states:

Design criteria and assumptions shall be documented and should be made available for operation of the system

Table 7 Section 6.3.1.3

6.3.1.3 Perceived Indoor Air Quality.The criteria to achieve the design level of acceptability shall be specified in terms of the percentage of building occupants and/or visitors expressing satisfaction with perceived indoor air quality.”

Table 8 Section 6.3.1.4

6.3.1.4 Design Approaches. Select one or a combination of the following design approaches to determine minimum space and system outdoor airflow rates and all other design parameters deemed relevant (e.g., air cleaning efficiencies and supply airflow rates).

(a) Mass balance analysis.

(b) Design approaches that have proved successful in similar buildings…

(c) Approaches validated by contaminant monitoring and subjective occupant evaluations in the completed building.

(d) Application of one of the preceding design approaches (a,b, or c) to specific contaminants

and the Ventilation Rate Procedure would be used to determine the design ventilation rate of the space and the IAQ Procedure would be used to address the control of the specific contaminants through air cleaning or some other means.[1] within a reasonable time after installation. See Sections 4.3, 5.2.3, 5.17.4 and 6.3.2 regarding assumptions that should be detailed in the documentation.’1-1

Within Section 5.2.3, Ventilation Air Distribution requires us to:

… specify minimum requirements for air balance testing or reference applicable national standards for measurement and balancing airflow.[1]

Providing permanently installed instruments and controls that result in and verify compliance with ASHRAE Standard 62.1 is perhaps one of the best reasons to provide such devices as part of any HVAC system design. Continuous data inputs may also be used to aid start-up, test and balance, commissioning, and measurement and verification (M&V) for energy usage and ongoing diagnostics. More precise and more reliable control could be viewed as a bonus.

Construction and System Start-Up

Section 7 addresses the construction and start-up phases of the project and has been included because a significant number of documented IAQ cases were a result of activities which took place during these phases of the project. The construction phase, addressed in Section 7.1 of the Standard, applies to “ventilation systems and the spaces they serve in new buildings and additions to or alterations in existing buildings.”[1] The Standard addresses both the protection of materials and protection of occupied areas.

Mechanical barriers are specified to protect occupied areas from construction-generated contaminants. In addition, the HVAC system must be able to maintain occupied spaces at positive pressures with respect to the construction areas. In many cases, the HVAC system does not have the adequate capacity and controls to provide a barrier to the migration of contaminants using positive pressurization flow. Designers must consider the condition of the existing ventilation system and its ability to maintain a pressurized environment for spaces expected to continue occupancy, prior to initiating physical construction activities at the site.

The start-up phase, covered in Section 7.2, provides guidelines for air balancing, testing of drain pans, ventilation system start-up, testing of damper controls, and documentation requirements.

Section 7.2.2, Air Balancing, requires that systems be balanced, “at least to the extent necessary to verify conformance with the total outdoor air flow and space supply air flow requirements of this standard.”[1] Unfortunately, the airflow rates of the system will vary after this activity has occurred, in most systems, for reasons discussed in the analysis of Section 5, Systems and Equipment. When applied in accordance with the manufacturer’s recommendations, some airflow measuring devices only require the verification of operation by test and balance professionals. This TAB “snapshot” of airflow rates is analogous to providing a one-time setup for temperature control, which obviously would not be very effective. Providing permanently mounted airflow measuring stations would also support compliance with and reduce the time required to supply the documentary requirements for ventilation set forth in Section 7.2.6 (c).

Operations and Maintenance

All systems constructed or renovated after the date the Standard’s 2001 version parent document was originally adopted are required to be operated and maintained in accordance with the provisions set forth in these newer sections of the Standard. It is important to recognize that if the building is altered or if its use is changed, the ventilation system must be reevaluated. Buildings that are likely to be changed or altered during their life spans should consider including a robust HVAC system design that takes into account changes in airflow rate requirements imposed by this Standard. Of course, provisions for permanently mounted airflow measurement devices and controls would significantly reduce both the cost and time associated with such changes as long as the HVAC load capacity could accommodate future requirements.

Section 8.4.1.7 addresses sensors. “Sensors whose primary function is dynamic minimum outdoor air control, such as flow stations.. .”[1] is discussed in this section even though they were not mentioned under Section 5, Systems and Equipment. Section 8.4.1.7 requires that sensors have their accuracy verified “once every six months or periodically in accordance with the Operations and Maintenance Manual.”[1] The Operations and Maintenance Manual for some airflow measuring devices does not recommend periodic recalibration. Permanently calibrated airflow instrumentation has a significant advantage over other airflow measuring technologies and CO2 sensors, whose transmitters are subject to frequent adjustments, zeroing, or regular calibrations to correct for analog electronic circuitry and sensor drift.

However, Section 8.4.1.8 (Outdoor Air Flow Verification) only requires the verification of airflow rates “once every five years.”[1] Because external and system factors change continuously, clearly influencing outdoor airflow rates, this requirement does little to assure that proper ventilation rates are maintained under normal operation at different times of the day and the year. It effectively places the burden of verification of new building/system performance on the building operator, who is often not in a position to make such a determination.

This apparent contradiction with Section 8.4.1.7 will likely be examined by the ASHRAE SSPC62.1 committee in the near future. Permanent outdoor airflow measuring stations would provide continuous verification and the necessary control inputs to maintain ventilation requirements, automatically minimizing intake rates for energy usage and preventing other control inputs from causing a maximum intake limit from being exceeded.

CONCLUSIONS

American Society of Heating and Refrigeration and Air-Conditioning Engineers Standard 62.1 prescribes ventilation rates for acceptable IAQ. It should be clear to the building operator and the design professional that the dynamic nature of mechanical ventilation requires dynamic control to insure the continuous maintenance of specific predetermined conditions. As a rate-based standard, continuous airflow measurement should logically be a central component of any effective control strategy to assure acceptable IAQ and minimize the costs of energy to provide it.