Abstract

The world is now facing the reality that fossil fuels are a finite resource that will be exhausted someday, that global consumption is outpacing the discovery and exploitation of new reserves, and that the global environment is worsening due to increasing greenhouse gas (GHG) emissions caused by traditional fossil fuels. As a result, there is a renewed push for alternative energy technologies, as well as technologies that can enhance recovery, transportation, and energy utilization and conversion efficiencies. In this entry, a review of current alternative energy technologies and their relevance in various energy sectors will be offered, including their most recent progress and the remaining challenges to overcome. Technology barriers and research/development opportunities for further growth in each category are outlined, and future projected growth is discussed in brief.

ALTERNATIVE ENERGY TECHNOLOGIES

World energy consumption is expected to grow continuously over the next two decades. Much of the growth in new energy demand is expected to come from countries of the developing world, such as Asia. At present, developing countries, comprising more than 75% of the world’s population, account for only about one-third of the world’s electricity consumption, but this is expected to increase rapidly. Fossil fuels (such as oil, natural gas, and coal) have been the world’s primary energy source for several decades due to their competitive low prices. However, with the high world oil prices brought on by the oil price shocks after the OPEC oil embargo of 1973-1974 and the Iranian Revolution of 1979, the use of oil for electricity generation has been slowing since the mid-1970s, and alternative energy sources, such as nuclear power, increased rapidly from the 1970s through the mid-1980s. In addition, given the recent increase in prices of fossil fuels and world compliance with carbon emission reduction policies such as the Kyoto Protocol, nonfossil fuels (including nuclear power and renewable energy sources such as hydroelectricity, geothermal, biomass, solar, and wind power) could become more attractive.

Renewable energy resources have served humans for hundreds of years in the form of water wheels, windmills, and biomass fuels during the industrial revolution. Modern efforts to harness these resources increased sharply after the oil crisis in 1970s, which provided incentive to bring these renewable sources to market to produce electricity for all economic sectors, fuels for transportation, and heat for buildings and industrial processes. Theoretically, renewable energy sources can meet the world’s energy demand many times over. After two decades of dramatic technical progress, renewable energy technologies now have the potential to become major contributors to the global energy supply. Some of the technologies are already well established while others require further efforts in research, development, and deployment to become economically competitive in the traditionally fossil fuel-dominated market. However, renewable energy technologies can now be considered major components of local and regional energy systems, as they have become both economically viable and environmentally preferable alternatives to fossil fuels. For each energy demand sector, such as electric power, industrial process and building, and transportation fuels, there are several renewable energy technologies being developed. If any one technology fails to meet the technological and economic goals of its demand sector, at least one other technology will be available for that sector.

Biomass Energy

Biomass refers to green plants or almost any organic product derived from plants. It is actually a form of solar energy that is collected and stored as chemical energy by green plants and then converted to more convenient energy forms (i.e., electric energy and thermal energy) or energy carrier fuels in solid, liquid, and gaseous states. Biomass is the only renewable energy resource that can be converted to liquid fuels like oil. Biomass is used in four main ways: direct combustion, electric power generation, conversion to gas for use as fuel or chemical feedstock, and conversion to liquid fuels. There are abundant biomass resources, including trees and grasses, starch and oil seeds, sawdust, wood waste, agricultural residues, food-processing waste, paper, and municipal solid waste (MSW). Biomass energy commonly refers to both traditional biomass and modern biomass.

Traditional Biomass: traditional biomass is chemical energy directly converted through combustion into thermal energy for heating and cooking. It has been used since humans first discovered fire; it was the first application of renewable energy history. It has taken such forms as fuel wood, animal waste, and crop residue burned in stoves. An estimated 2.4 billion people in developing countries use biomass as their primary fuel for cooking and heating. Traditional biomass provides about 7%-14% of the global primary energy supply and averages 30%-45% of the energy used in developing countries, though some developing countries approach 90%.[1] Today, new biomass stoves and heaters have improved efficiency. About three quads of energy are being provided in the United States today by wood— roughly half the contribution of nuclear power. Municipal solid waste combustion also provides a small amount of process heat. At present, the availability of low-priced wood is the key constraint for its market growth.

Modern Biomass: modern biomass is converted into electricity, transport fuels, or chemicals (e.g., ethanol, methane, and biodiesel) using related process facilities. For example, China and India convert animal and plant wastes into methane for lighting, heating, cooking, and electricity generation, using bacteria to decompose biomass into biogas digesters. Modern biomass accounts for 20% of Brazil’s primary energy supply, made possible by significant increases in the past 20 years in the use of ethanol fuels for vehicles and sugarcane waste for power generation. Global annual ethanol production from biomass is estimated at 18 billion liters, 80% of which is in Brazil.[2] Gasification of biomass for methane production may provide a competitive source for the nation’s natural gas market. Meanwhile, the conversion of a large portion of MSW and sewage sludge to methane via anaerobic digestion may provide an attractive alternative means of disposing of such wastes.

Biomass Fuels

There are two kinds of biomass-derived liquid fuels for vehicles: ethanol fuel and biodiesel.

Ethanol: ethanol is an alcohol fuel traditionally fermented from corn kernels (corn alcohol). In 2002, 2.13 billion gallons of ethanol were produced in the United States (up 20% from 2001), which was still a small amount compared to U.S. oil imports (less than 2.6%). Ethanol can power specially designed vehicles that run on pure ethanol, or it can be mixed with gasoline or diesel fuel as an additive for use in ordinary vehicles to boost combustion and reduce vehicle emissions. According to the U.S. Environmental Protection Agency, motor vehicle emissions of carbon monoxide can be reduced by 25%-30% with the use of ethanol blended with gasoline. Ethanol-gasoline blends can also reduce ozone levels that contribute to urban smog. In addition, the combustion of ethanol produces 90% less carbon dioxide than gasoline. A blend of 10% ethanol and 90% gasoline has been widely used throughout the nation for many years. Higher level blends of 85 and 95% ethanol are being tested in government fleet vehicles, flexible-fuel passenger vehicles, and urban transit buses. There are already nearly 50,000 such vehicles already in operation, and their use is expected to grow as federal, state, municipal, and private fleet operators seek to comply with the alternative fuel requirements of the Energy Policy Act of 1992 and the Clean Air Act Amendments of 1990.

However, market issues related to ethanol production efficiency, cost competition with gasoline, the commercial viability and costs of specially designed ethanol-only vehicles, the fuel distribution infrastructure, and ratios of ethanol to gasoline in gasohol blending a challenge the attractiveness of ethanol as an alternative fuel. In addition, corn requires high amounts of energy (in the forms of fertilizer, farm equipment fuel, and coal-fire electricity) to grow, harvest, and process. Some research has shown that ethanol consumes more energy than it produces when traditional methods of production are utilized. As a result, renewable energy research has turned its focus toward a new biotech method of producing ethanol—termed bioethanol—from cellulosic biomass, such as agriculture waste products and MSW. Feedstocks include corn husks, rice straws, rice hulls, wood chips, sugarcane, forest thinnings (which also prevent wildfires), waste newspaper, and grasses and trees cultivated as energy crops. Bioethanol requires less energy to produce than ethanol and uses materials that are currently burned or buried. The biological production of ethanol involves hydrolysis of fibrous biomass, using enzymes or acid catalysts, to form soluble sugars, followed by microbial conversion of sugars to ethanol. As a result of technical advances, such as the genetic engineering of specialized enzymes and microbes, the cost of bioethanol production in the lab was decreased from $3.60/gallon in 1980 to about $1.20 in the 1990s.[3] Ultimately, the goal is for bioethanol to become competitive with gasoline in price. Research focuses on producing low-cost enzymes to break down cellulose, improving microorganism performance, producing suitable energy crops, and demonstrating ethanol production from a variety of biomass feedstocks.

Unfortunately, the transition of bioethanol from the laboratory to the highway has been slow. Though biomass is a renewable resource, ethanol is limited by available land. According to a recent Department of Energy (DOE)report, five quads of bioethanol would be needed to provide 45% of the fuel used in gasoline vehicles,[4] which would use current cropland and grassland to produce 63% of bioethanol—as shown in Table 1.

The EIA reports that of the 10.38 MBPD of motor fuel consumed by motor vehicles in the United States in 1999, 0.28 MBPD (2.7%) was comprised of alternative or replacement fuels. More than 90% of this consisted of methyl-tertiary butyl ester (MTBE) (0.2 MBPD) and ethanol (0.06 MBPD) blended with gasoline. Alternative fuels, such as compressed natural gas, methanol, and LPG comprise only 0.02 MBPD.[5] However, MTBE, a petroleum-based oxygenate additive for reformulated gasoline, is toxic and can threaten the safety of community water supplies. When compared with MTBE, ethanol provides extra oxygen, increasing combustion temperatures and efficiency, and lower emissions. Ethanol is expected to replace MTBE as the oxygenate for reformulated gasoline in the near future. As a result, ethanol use increased from 133 trillion Btu in 2001 to 156 trillion Btu in 2002, and surged to 220 trillion Btu in 2003 (see Fig. 1). Production is projected to increase to 278,000 barrels per day in 2025, with about 27% of the growth from conversion of cellulosic biomass (such as wood and agricultural residues) due to rapid improvement in the technology.1-6-1

Today, more than 60% of Brazil’s sugarcane production goes to produce ethanol. Technological advances have continued to improve the economic competitiveness of ethanol and gasohol relative to conventional gasoline, although the price of oil and competitive forces in global automotive technology greatly affects ethanol’s prospects. In 2000, over 40% of automobile fuel consumption and 20% of total motor vehicle fuel consumption in Brazil was ethanol, displacing the equivalent of 220,000 barrels of oil per day. Moreover, ethanol is not the only fuel that can be produced from biomass. About 1.2 billion gallons of methanol, currently made from natural gas, are sold in the United States annually, with about 38% of this used in the transportation sector. (The rest is used to make solvents and chemicals). Methanol can also be produced from biomass through thermochemical gasification.

Table 1 Four sources required for production of five quads of bioethanol

| Source | Portion of ethanol (%) | Note |

| Grassland | 19 | Using 10% of current grassland |

| Agricultural waste | 25 | Using 100% agriculture waste |

| Waste wood | 12 | Using 100% waste wood |

Fig. 1 Ethanol and MTBE consumption in the transportation sector (1992-2003).

Biodiesel: biodiesel is defined as the mono-alkyl esters of fatty acids processed from any vegetable oil or animal fat. Biodiesel is an alternative fuel for diesel engines that is receiving great attention around the world because it is renewable, and 100% biodiesel eliminates sulfur emissions and reduces particulate matter and other pollutants by 50%. It does increase emissions of one smog-producing pollutant, nitrogen oxide, NOx, but this can be solved by adjusting engine timing. Biodiesel generally has a lower heating value that is 12% less than No. 2 diesel fuel on a weight basis (16,000 Btu/lb compared with 18,300 Btu/ lb). Because biodiesel has a higher density, the lower heating value is only 8% less on a volume basis (118,170 Btu/gallon for biodiesel compared with 129,050 Btu/gallon for No. 2 diesel fuel). Biodiesel can be used in its pure form or in blends with diesel fuel in diesel engines with no modification. In 2000, heavy trucks used 30% as much fuel as light vehicles. Diesel fuel, currently produced from petroleum, is also being produced in limited quantities from soybeans, but research has shown that diesel fuel can also be produced from less costly and more abundant sources, such as the natural oils occurring in algae and pyrolysis of biomass, other vegetable oils (such as corn oil, canola oil, cottonseed oil, mustard oil, and palm oil), animal fats, and waste oils. Total annual production of U.S. fats and oils is about 35.3 billion pounds per year (less than the equivalent of 4.64 billion gallons of biodiesel).[8] The dominant factor in biodiesel production is the feedstock cost, with capital cost contributing only about 7% of the product cost. Sales of biodiesel fuels have exploded thirtyfold since 1999 to 15 million gallons and over 33 million gallons in 2000, per the EIA. The United States has the capacity to produce much more biodiesel, and its output is projected to grow by 1.8% per year.[9]

United States farms and fields have yielded some homegrown energy choices, like biodiesel and ethanol, but it is still hard for them to compete with fossil fuel, with its relatively low prices and robust infrastructure, in the market. Currently, a subsidy is offered by the Department of Agriculture’s Commodity Credit Corporation for the promotion and production of biodiesel. However, biodiesel is as much as twice the cost of petroleum. It is obvious that biodiesel could not completely replace petroleum-based diesel fuel in the near future. Even with the unrealistic scenario that all of the vegetable oil and animal fat currently produced were used to produce biodiesel, only about 15% of the current demand for on-highway diesel fuel could be replaced.

Solar Energy

The sun’s energy is the primary source for most energy forms found on the earth. Nature’s energy resources are confined to two categories: earth-stored fossil residues and nuclear isotopes that are limited by the finite amounts that exist on the earth, and the radiation flux of solar energy that is clean, abundant, and renewable. Although solar energy holds tremendous potential to benefit the world by diversifying its energy supply, reducing dependence on fossil fuels, improving the quality of the global environment, and stimulating the economy by creating jobs in the manufacture and installation of solar energy systems, solar energy’s economic utility is limited by the finite rate at which the sun’s energy can be captured, concentrated, stored, and/or converted for use in the highest value energy forms, and by the land areas that societies can dedicate to harness it. The amount of solar energy received across U.S. latitudes is approximately 22 quads per year per 4000 km2 (about a million acres) on average. ] Thus, about 40-80 thousand km2 of land—roughly two to four times the size of Massachusetts—could supply about 20 quads, or 20%-25%, of today’s total U.S. energy requirements (currently, PV solar cells convert 10%-20% of incident radiation directly to electricity).

Solar Energy Prospects

According to the outline of the U.S. DOE energy technologies program,[11] solar energy will increase the world’s energy supply and enhance the reliability of the global energy infrastructure, thus creating a more stable environment for economic growth. The distributed, modular characteristics of solar energy offer tremendous flexibility for both grid-connected and off-grid electricity applications. Distributed energy technologies are expected to supply an increasing share of the electricity market to improve power quality and reliability problems, such as power outages and disturbances. With improved technology supported by the U.S. DOE, the cost of solar energy has dropped substantially in the past decade and continues to decline. The projected costs (shown as dashed lines in Fig. 2) are based on continuing the proposed budget support for the DOE Solar Program.

The long-term cost goals are even more ambitious. For example, the goal for photovoltaics, which will become an economically competitive alternative to traditional fossil fuel energy, is $0.06 per kilowatt-hour (kWh) in 2020.

Wind Energy

Wind is a form of solar energy. Winds are caused by the uneven heating of the atmosphere by the sun, the irregularities of the earth’s surface, and rotation of the earth. Wind flow patterns are modified by the earth’s terrain, bodies of water, and vegetation. Wind energy or wind power describes the process by which the wind is used to generate mechanical power or electricity. This mechanical power can be used for specific tasks (such as grinding grain or pumping water) or fed to a generator that can convert this mechanical power into electricity. Since early recorded history, people have been harnessing the energy of the wind. Wind propelled boats along the Nile River as early as 5000 B.C.; by 200 B.C., simple windmills in China were pumping water.[2] Commonly called wind turbines, machines that convert the kinetic energy in the wind into electricity through a generator appeared in Denmark as early as 1890. In the 1940s, the largest wind turbine of the time began operating on a Vermont hilltop known as Grandpa’s Knob, which rated at 1.25 MW in winds of about 30 mph and fed electric power to the local utility network for several months during World War II.[12] The popularity of using wind energy has always fluctuated with the price of fossil fuels. When fuel prices fell after World War II, interest in wind turbines declined. But when the price of oil skyrocketed in the 1970s, so did worldwide interest in wind turbine generators. The rapid progress in wind turbine technology has refined old ideas and introduced new ways of converting wind energy into useful power. Many of these approaches have been demonstrated in “wind farms” or “wind power plants” (groups of turbines), which feed electricity into the utility grid in the United States and Europe. Since the 1970s, wind energy has expanded its role in electricity generation. The worldwide installed capacity of grid-connected wind power has now exceeded 40 GW, corresponding to an investment of approximately $40 billion.[12] A demand for clean, diverse sources of electricity and state and federal incentives to stimulate the market have contributed to wind energy’s growth in the United States. Wind energy installations in the United States increased during the past decade from about 1800 MW in 1990 to more than 6000 MW at the end of 2003, enough to power almost three million average homes. The average U.S. wind energy growth rate for the past five years was 24%. This growth can be attributed to a greatly reduced cost of production, from 80 cents (current dollars) per kWh in 1980 to cents per kWh in 2002. The global wind energy installed capacity has increased exponentially over a 25-year period, and in the process, the cost of energy (COE) from wind power plants has been reduced by an order of magnitude, becoming very close in cost to power from modern combined-cycle power plants in some locations. According to the American Wind Energy Association, as much as 13,500 additional megawatts of wind capacity may be installed worldwide in the next decade.[23] Wind energy is the world’s fastest growing energy source and will power industry, businesses, and homes with clean, renewable electricity for many years to come.

Fig. 2 The cost roadmap of solar energy technology.

Wind Energy Technology Development

The considerable potential of wind energy was not tapped before the 1980s because the wind turbine technology was not competitive with most central fossil fuel-fired generating stations. But over the past two decades, the rapid progress in wind turbine technologies has led to more cost-effective wind turbines that are more efficient in producing electricity. The progress was mainly motivated by the oil embargoes and fuel price escalations of the 1970s and more recently by environmental concerns. The goal is to develop cost-effective, low wind-speed turbines for Class sites (13-mph average annual wind speed) that can produce electricity onshore for $0.03/kWh and offshore for $0.05/kWh by the end of 2012. This will open up 20 times more U.S. land for wind energy development, and because many of these sites tend to be closer to urban load centers, the problem of transmission line expansion will be greatly simplified. But the current turbine designs are not well suited to low wind-speed sites and have only limited potential to achieve lower energy costs. If such technology can be successfully developed, the wind resources across the Great Plain states could potentially generate more electricity than is currently consumed by the entire nation.[13] Although wind power plants have relatively little impact on the environment compared to other conventional power plants, there is some concern over the noise produced by the rotor blades, aesthetic (visual) impacts, and the danger to birds, which have been killed by flying into the rotors. Most of these problems have been resolved or greatly reduced through technological advances or by properly siting wind plants.

Future technology improvements for low-speed wind technology must address three principal areas:

• Turbine rotor diameters must be larger to harvest the lower-energy winds from a larger inflow area without increasing the cost of the rotor.

• Towers must be taller to take advantage of the increased wind speed at greater heights.

• Generation equipment and power electronics must be more efficient to accommodate sustained light wind operation at lower power levels without increasing electrical system costs.

Hydrogen and Fuel Cells

Hydrogen is the simplest element; an atom consists of only one proton and one electron. It is also the most plentiful element in the universe. Although in many ways hydrogen is an attractive replacement for fossil fuels, it does not occur in nature as the fuel H2. Rather, it occurs in chemical compounds, such as water or hydrocarbons that must be chemically transformed to yield H2. Hydrogen is found in water and hydrocarbon organic compounds that make up many of our fuels, such as gasoline, coal, natural gas, methanol, and propane. Although President Bush has called hydrogen a “pollution free” technology, extracting hydrogen from its most common source, water, requires electricity that may come from fossil fuels, such as coal or nuclear energy. Hydrogen, like electricity, is a carrier of energy, and like electricity, it must be produced from a natural resource. Nevertheless, it promises substantial contributions to global energy supplies and minimal environmental impact in the long term.

Hydrogen

Hydrogen is the simplest chemical fuel (essentially a hydrocarbon without the carbon) that makes a highly efficient, clean-burning energy carrier and a secondary form of energy that has to be produced like electricity. When hydrogen is used to power a special battery called a fuel cell, its only waste product is water. Hydrogen-powered fuel cells and engines could become as common as the gasoline and diesel engines of the late 20th century and could power cars, trucks, buses, and other vehicles, as well as homes, offices, and factories. Hydrogen has the potential to fuel transportation vehicles with zero emissions, provide process heat for industrial processes, supply domestic heat through cogeneration, help produce electricity for centralized or distributed power systems, and provide a storage medium for electricity from renewable energy sources. Some envision an entire economy based on hydrogen in the future.[14] At present, most of the world’s hydrogen is produced from natural gas by a process called steam reforming. However, producing hydrogen from fossil fuels would not be an advancement because steam reforming does not reduce the use of fossil fuels, but rather shifts them from end use to an earlier production step; in other words, steam reforming would still release carbon to the environment in the form of CO2. Thus, to achieve the benefits of the hydrogen economy, the hydrogen must be produced more cost effectively from nonfossil resources, such as water, using a renewable energy source like wind or solar. Although the potential benefits of a hydrogen economy are significant, many barriers to commercialization—technical challenges, and otherwise—must be overcome before hydrogen can offer a competitive alternative for consumers.

Commercial Barriers. The commercial barriers to the widespread use of hydrogen are the high cost of hydrogen production, low availability of hydrogen production systems, the challenge of providing safe production and delivery systems (i.e., economical storage and transportation technologies), and public acceptance.

• Hydrogen Storage. Hydrogen has a low energy density in terms of volume, making it difficult to store amounts adequate for most applications in a reasonably-sized space. This is a particular problem for hydrogen-powered fuel cell vehicles, which must store hydrogen in compact tanks. Hydrogen is currently stored in tanks as a compressed gas or cryogenic liquid. The tanks can be transported by truck or the compressed gas can be sent across distances of less than 50 miles by pipeline. Other options are to store hydrogen in a cryogenic liquid state or solid state. Technologies that store hydrogen in a solid state are inherently safer and have the potential to be more efficient than gas or liquid storage. These are particularly important for vehicles with on-board storage of hydrogen. High-pressure storage tanks are currently being developed, and research is being conducted into the use of solid-state storage technologies, such as metal hydrides, which involve chemically reacting the hydrogen with a metal; carbon nanotubes, which take advantage of the gas-on-solids adsorption of hydrogen and retain high concentrations of hydrogen; and glass microspheres, which rely on changes in glass permeability with temperature to fill the microspheres with hydrogen and trap it there. However, the statistical cost, durability, fast-fill, discharge performance, and structural integrity data of hydrogen storage systems must be improved before proceeding with commercialization.

• Safety, Codes, and Standards. Hydrogen, like gasoline or any other fuel, has safety risks and must be handled with due caution. Unlike the handling of gasoline, handling hydrogen will be new to most consumers. Therefore, developers must optimize new fuel storage and delivery systems for safe everyday use, and consumers must become familiar with hydrogen’s properties and risks. Codes and standards are needed to ensure safety as well as to commercialize hydrogen as a fuel.

• Public Acceptance. Finally, public acceptance of hydrogen depends not only on its practical and commercial appeal, but also on its record of safety in widespread use. Because a hydrogen economy would be a revolutionary change from the world we know today, educating the general public, training personnel in the handling and maintenance of hydrogen system components, adopting codes and standards, and developing certified procedures and training manuals for fuel cells and safety standards will foster hydrogen’s acceptance as a fuel.

Technology Roadmap (Present-2030). Technical challenges for hydrogen commercialization include cost-effective, energy-efficient production technologies and safe, economical storage and transportation technologies. The U.S. DOE has provided a national version of America’s transition to a hydrogen economy to 2030 or beyond.[15] This technology roadmap consists of three steps. The first step toward a clean energy future will focus on technology development and initial market penetration to build on well-known commercial processes for producing, storing, transporting, and using hydrogen. In the mid-term, as hydrogen use increases and hydrogen markets grow, the expansion of the market and infrastructure investment will make the cost of hydrogen and fuel cell economically competitive with traditional fossil fuels. For the long term, when the market and infrastructure are more fully developed, wider uses of more cost-effective advanced technologies will be an important step toward a hydrogen economy.[15]

Today, large centralized steam methane reformers are used to produce hydrogen for chemical industries. This will continue to be the likely choice for meeting increased hydrogen demand in the near term. Electrolyzers are also used to produce the high-purity hydrogen needed for electronics manufacturing and other specialty uses. Compressed hydrogen tanks are available today, although the low energy density of hydrogen means large tanks are needed. As a liquid, hydrogen’s energy density is substantially improved, but boil-off losses are a concern. Today, hydrogen is transported by pipeline or over the road in cylinders, tube trailers, and cryogenic tankers.

A small amount is shipped by rail car or barge. Hydrogen has also long been used in the space program as a propellant for the space shuttle and in the on-board fuel cells that provide the shuttle’s electric power. New combustion equipment is being designed specifically for hydrogen in turbines and engines, and vehicles with hydrogen internal combustion engines have been demonstrated. Also being tested is the combustion of hydrogen-natural gas blends to improve the yield of natural gas reforming in an effort to lower cost and raise efficiency. Fuel cells are in various stages of development for transportation, stationary, and portable applications. Incremental advances of current technologies provide a low-risk commercial entry into the hydrogen economy.

Fuel Cells

The widespread use of hydrogen as an energy source in the world could help address concerns about energy security, global climate change, and air quality. Fuel cells are an important enabling technology for a future hydrogen economy and have the potential to revolutionize power generation, offering cleaner, more efficient alternatives to the combustion of gasoline and other fossil fuels. Fuel cells promise to be a safe and effective way to use hydrogen for both vehicles and electricity generation. Although these applications would ideally run off pure hydrogen, in the near term they are likely to be fueled with natural gas, methanol, or even gasoline. If the fuel cell is to become the modern steam engine, basic research must provide breakthroughs in understanding, materials, and design to make a hydrogen-based energy system a vibrant and competitive force. Fuel cell technology is not a new invention. Actually, fuel cell development predated the internal combustion engine, but lacked a commercial venue until NASA decided to incorporate fuel cells in spacecrafts during the 1960s. Phosphoric acid fuel cells are already commercially available and can generate electricity in 200-kW capacities selling for $3/W, using natural gas as the source of hydrogen; molten carbonate has also been demonstrated at large (2-MW) capacities.

A fuel cell works like a battery but does not run down or need recharging. Fuel cells convert hydrogen—hydrogen gas or hydrogen reformed within the fuel cell from natural gas, alcohol fuels, or some other source—directly into electrical energy with no combustion. They will produce electricity and heat as long as fuel (hydrogen) is supplied. A fuel cell consists of two electrodes, a negative electrode (or anode) and a positive electrode (or cathode), sandwiched around an electrolyte. Hydrogen is fed to the anode, and oxygen is fed to the cathode. Activated by a catalyst, hydrogen atoms separate into protons and electrons, which take different paths to the cathode. The electrons go through an external circuit, creating a flow of electricity. The protons migrate through the electrolyte to the cathode, where they reunite with oxygen and the electrons to produce water and heat.

Fuel cell technologies are significantly more energy efficient than combustion-based power generation technologies. A conventional combustion-based power plant typically generates electricity at efficiencies of 33%-35%, while fuel cell plants can generate electricity at efficiencies of up to 60%. When fuel cells are used to generate electricity and heat (cogeneration) they can reach efficiencies of up to 85%. Internal-combustion engines in today’s automobiles convert less than 30% of the energy in gasoline into power that moves the vehicle. Vehicles using electric motors powered by hydrogen fuel cells will be much more energy efficient, utilizing 40%-60% of the fuel’s energy.[28]

Technology Challenges. Although NASA has used hydrogen fuel cells for space missions since the 1960s, terrestrial applications are still in their infancy. The lack of an economical process for hydrogen production and suitable storage methods are two of the greatest obstacles to commercialization, especially in the transportation sector. Research goals include developing technologies to produce hydrogen from sunlight and water and biomass; developing low-cost and low-weight hydrogen storage technologies for both stationary and vehicle-based applications, such as carbon nanotubes and metal hydrides; and developing codes and standards to enable the widespread use of hydrogen technologies. Technological development is addressing the following key challenges in the commercialization of fuel cell and hydrogen infrastructure technologies[28]:

• Cost. Cost is the greatest challenge to fuel cell development and adaptation, and it is a factor in almost all other fuel cell challenges, as well. Materials and manufacturing costs are high for fuel cell components (i.e., catalysts, membranes, bipolar plates, and gas diffusion layers). Statistical data for fuel cell vehicles that are operated under controlled, real-world conditions are very limited and often proprietary. For example, some fuel cell designs require expensive, precious-metal catalysts, and others require costly materials that are resistant to extremely high temperatures. Currently, the costs for automotive internal combustion engine power plants are about $25-$35/kW. The targeted cost for a fuel cell system to be competitive in transportation applications is around $30/kW, and the acceptable price point for stationary power systems is considerably higher (i.e., $400-$750/kW for widespread commercialization and as much as $1000/kW for initial applications).

• Durability and Reliability. All fuel cells are prone, in varying degrees, to catalyst poisoning, which decreases fuel cell performance and longevity. The durability and reliability of fuel cell systems operating over automotive drive cycles has not been established. Vehicle fuel cell power systems will be required to achieve the same level of durability and reliability of current engines over the full range of vehicle operating conditions at 40°C-80°C (i.e., 5000 h lifespan or about 150,000 miles equivalent). Stationary fuel cells must achieve greater than 40,000 h of reliable operation at — 35 to 40°C to meet market requirements. Fuel cell component degradation and failure mechanisms are not well understood. The cycle life of hydride storage systems also needs to be evaluated in real-world circumstances.

• System Size. The volume and weight of current fuel cell systems are too high to meet the packaging requirements for transportation or stationary applications. System volume minimization and weight reduction will focus not only on the fuel cell stack, but also on the ancillary components and major subsystems making up the balance of power system (e.g., fuel processor, compressor/expander, and sensors).

• Air, Water, and Thermal Management. Fuel cell performance and efficiency must meet or exceed that of competing technologies in order to be commercially accepted. Today’s compressor technologies are not suitable for fuel cell applications that need low power consumption and less packaging volume. Vehicle fuel cell systems must start rapidly from any ambient condition with minimal fuel consumption. Cost-effective thermal and water management technologies are needed, including heat recovery and water utilization, cooling, and humidification. The low operating temperature of proton exchange membrane (PEM) fuel cells results in a relatively small difference between the operating and ambient temperatures, which need advanced technologies to allow high operating temperatures and to improve combined heat and power system performance.

Nuclear Energy

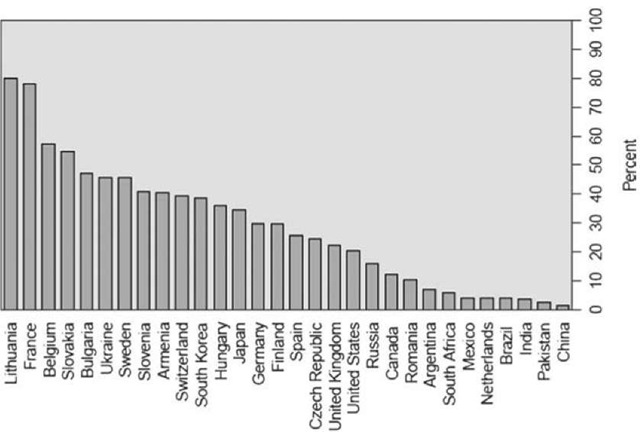

Nuclear technology uses the energy released by splitting the atoms of certain elements. It was first developed in the 1940s, and during the Second World War, research initially focused on producing bombs by splitting the atoms of either uranium or plutonium. Only in the 1950s did attention turn to peaceful applications of nuclear fission, notably power generation. Today, the world produces as much electricity from nuclear energy as it did from all sources combined in 1960. Civil nuclear power, with some 440 commercial nuclear power reactors in 30 countries, can now exceed 12,000 reactor years of experience, and nuclear power supplies 16% of global needs with a total installed capacity of over 360,000 MWe.[18] This is more than three times the total generating capacity of France or Germany from all sources. The economics of nuclear power may be more favorable in countries where other energy fuels (mostly imported) are relatively expensive. In 2002, nineteen countries depended on nuclear power for at least 20% of their electricity generation (Fig. 3), while three quarters of both France’s and Lithuania’s power are derived from nuclear energy.

However, accidents at Three Mile Island in the United States in 1979 and at Chernobyl in the Soviet Union in 1986 pushed public opinion and national energy policies away from nuclear power as a source of electricity. But, after nearly two decades of the antinuclear tide, nuclear energy today is at a turning point. Nuclear power plant performance has shown a steady improvement over the past 10-15 years: one quarter of the world’s reactors have load factors of more than 90% and almost two-thirds do better than 75%, compared to about a quarter of them in 1990.

Fig. 3 Nuclear shares of national electricity generation, 2002.

Nuclear power is the only mature, noncarbon electricity generation technology that can significantly contribute to the long-term, globally sustainable energy mix. Besides providing electricity, nuclear energy contributes to a number of policy goals, including achieving energy independence, keeping the air clean, and reducing carbon emissions. European countries have begun construction of a nuclear reactor, and six more are likely to be constructed in the next decade. The U.S. Nuclear Power 2010 program aims to build new nuclear power plants in the United States by the end of the decade, and expects that the advanced reactor designs will produce electricity in the range of $1000-$1200 per kW of electricity. The highest growth in nuclear generation is expected in the developing world, where consumption of electricity from nuclear power is projected to increase by 4.1% per year between 2001 and 2025. Developing Asia, in particular, is expected to see the largest increase in nuclear generating capacity, accounting for 95% of the total increase in nuclear power capacity for the developing world. Of the 44 gigawatts of additional installed nuclear generating capacity projected for developing Asia, 19 gigawatts are projected for China, 15 gigawatts are projected for South Korea, and 6 gigawatts are projected for India.[18]

Nuclear energy is, in many places, competitive with fossil fuel for electricity generation, despite relatively high capital costs and the need to internalize all waste disposal and decommissioning costs. If the social, health, and environmental costs of fossil fuels are also taken into account, nuclear energy is superior. A 2004 report from the University of Chicago, funded by the U.S. DOE, compares the power costs of future nuclear, coal, and gas-fired power generation in the United States. Various nuclear options are covered, and for ABWR or AP1000, they range from 4.3 to 5.0 c/kWh on the basis of overnight capital costs of $1200-$1500/kW, a 60-year plant life, a 5-year construction period, and 90% capacity. Coal yields 3.5-4.1 c/kWh and gas (CCGT) 3.5-4.5 c/kWh, depending greatly on fuel price.[17] When considering a minimal carbon control cost impact of 1.5 c/kWh for coal and 1.0 c/kWh for gas superimposed on the above figures, nuclear is even more competitive.

Overview of Nuclear Power Technology

The principles for using nuclear power to produce electricity are the same for most types of reactors. The energy released from continuous fission of the fuel atoms is harnessed as heat in either gas or water and it is used to produce steam. The steam is used to drive the turbines, which produce electricity (as in most fossil fuel plants).

In most naval reactors, steam drives a turbine directly for propulsion.

There are several components common to most types of reactors:

• Fuel. Pellets of uranium oxide (UO2) are usually arranged in tubes to form fuel rods. The rods are arranged into fuel assemblies in the reactor core.

• Moderator. This slows down the neutrons released from fission so that they cause more fission. The moderator is usually water, but may be heavy water or graphite.

• Control Rods. These are made from neutron-absorbing material, such as cadmium, hafnium, or boron, and are inserted into or withdrawn from the core to control the rate of reaction, or to halt it.

• Coolant. A coolant, such as a liquid or gas, circulates through the core so as to transfer heat from it. In light water reactors, the moderator also functions as coolant.

• Pressure Vessel/Pressure Tubes. This is a robust steel vessel containing the reactor core and moderator/ coolant, but it may also be a series of tubes holding the fuel and conveying the coolant through the moderator.

• Steam Generator. This is the part of the cooling system where the heat from the reactor is used to make steam for the turbine.

• Containment. The packaging structure around the reactor core is designed to protect it from outside intrusion and to protect those outside from the effects of radiation in case of any malfunction inside. It is typically a meter-thick concrete and steel structure.

Types of Nuclear Reactors

Most nuclear electricity is generated using just two kinds of reactors that were developed in the 1950s and have been improved since. In the United States, Westinghouse designed the first fully commercial pressurized water reactor (PWR) of 250 MWe, Yankee Rowe, which started up in 1960 and operated until 1992. Meanwhile, Argonne National Laboratory developed the first boiling water reactor (BWR). The first of this type, the Dresden-1 of 250 MWe, was designed by General Electric and started earlier in 1960. A prototype BWR, Vallecitos, ran from 1957 to 1963. By the end of the 1960s, orders were being placed for PWR and BWR reactor units of more than 1000 MWe.[19]

Pressurized Water Reactors utilize pressurized water as a moderator and coolant. The fuel, ceramic uranium dioxide, is typically encased in long zirconium alloy tubes. The uranium-235 is enriched from its original 0.7% abundance to 3.5%-5.0%.

Boil Water Reactors are similar to PWRs, except that the coolant water is allowed to boil, and steam passes from the top of the reactor directly to the turbine. Currently, more than 90 of these are operating throughout the world.

Table 2 Overview of commercial nuclear power reactors

| Reactor type | Main countries | Number | GWe | Fuel | Coolant | Moderator |

| Pressurized water reactor (PWR) | United states, France, Japan, Russia | 268 | 249 | Enriched U02 | Water | Water |

| Boiling water reactor (BWR) | United states, Japan, Sweden | 94 | 85 | Enriched U02 | Water | Water |

| Gas-cooled reactor (magnox &AGR) | UK | 23 | 12 | Natural U (metal), enriched U02 | co2 | Graphite |

| Pressurized heavy water reactor “CANDU” (PHWR) | Canada | 40 | 22 | Natural U02 | Heavy water | Heavy water |

| Light water graphite reactor (RBMK) | Russia | 12 | 12 | Enriched U02 | Water | Graphite |

| Fast neutron reactor (FBR) | Japan, France, Russia TOTAL | 4 441 | 1

381 |

Pu02 and U02 | Liquid sodium | None |

Advanced Gas-Cooled Reactors (AGRs) are the second generation of British gas-cooled reactors, using graphite moderators and carbon dioxide as coolant. The fuel is uranium oxide pellets, enriched to 2.5%-3.5%, in stainless steel tubes. The carbon dioxide circulates through the core, reaching 650°C, and then past steam generator tubes outside the core, but still inside the concrete and steel pressure vessel. Control rods penetrate the moderator, and a secondary shutdown system involves injecting nitrogen into the coolant.

Pressurized Heavy Water Reactors (PHWRs) are a Canadian reactor development headed down a quite different track, using natural uranium fuel and heavy water as a moderator and coolant. The first unit started up in 1962.

Fast Neutron Reactors (FBRs) (there is only one in commercial service) do not have a moderator and utilize fast neutrons, generating power from plutonium, while simultaneously making more of it from the U-238 isotope in or around the fuel. While these reactors get more than 60 times as much energy from the original uranium compared to normal reactors, they are expensive to build and must contend with resource scarcity before coming into their own.

Several different types of reactors in current commercial nuclear power plants are summarized in Table 2.

Several generations of reactors can be commonly distinguished. Generation I reactors were developed in the 1950s-1960s, and relatively few are still running today. They mostly used natural uranium fuel and graphite moderators. Generation II reactors developed in the 1970s-1980s are typified by the present U.S. fleet and most are in operation elsewhere. They typically use enriched uranium fuel and are mostly cooled and moderated by water. Pressurized water reactors and BWRs are known as light-water reactors. Around the world, with few exceptions, other countries have chosen light-water designs for their nuclear power programs, so that, today, 65% of the world capacity is PWR and 23% BWR.

Generation III reactors are advanced reactor designs developed in the 1990s. With enhanced safety, these reactors are more economical to build, operate, and maintain than the previous generation. The first Generation III system, a General Electric-designed advanced BWR, started operating in 1996 at the Kashiwazaki-Kariwa Nuclear Power Station in Japan. More than a dozen Generation III advanced reactor designs are in various stages of development. Some have evolved from the PWR, BWR, and CANDU designs above; some are more radical departures. The best-known radical new design is the Pebble Bed Modular Reactor (PBMR), which uses high-temperature helium to cool the reactor and drive the turbine directly. One of the limitations of current light-water reactor technology is that the thermal efficiency that can be achieved is limited to the achieved maximum temperature of 350°C. The PBMR is designed to achieve at least 900°C, which will give a thermal efficiency of up to 44%. This translates into roughly one-third more output than a conventional PWR. The first PBMR is currently planned for commercial operation in South Africa by around 2010.

Future Nuclear Power Technology

Generation I-III reactors recycle plutonium (and possibly uranium), while the future of nuclear reactors, known as Generation IV systems, have revolutionary reactor and fuel cycle systems.[29] Most will have closed fuel cycles that burn the long-lived actinides that form part of the spent fuel so that fission products are the only high-level waste. Many will also be fast neutron reactors. Six new designs, including three PWRs, three BWRs, and two high temperature gas-cooled reactors (HTRs), were identified for further study by the Generation IV International Forum (GIF), which was initiated in 2000 by a group of nine countries: Argentina, Brazil, Canada, France, Japan, South Africa, South Korea, the U.K., and the U.S. Switzerland became a member of the forum in February 2002, and the European Atomic Energy Community joined in July 2003. GIF is an international initiative whose goal is to develop nuclear energy systems that can supply future global needs for electricity, hydrogen, and other products. The aim is to deploy these systems no later than 2030 to provide competitively priced and reliable energy products, while satisfactorily addressing nuclear safety, waste, proliferation, and physical protection concerns. All six revolutionary nuclear reactor technology concepts identified for development by GIF operate at higher temperatures than the Generation II and III reactors currently in operation. The new systems range from a supercritical water-cooled reactor (SCWR), which operates at 510°C-550°C, to a helium-cooled very high-temperature gas reactor (VHTR), which has an operating temperature of 1000°C. Three of the six Generation IV concepts are fast reactor systems that are cooled either by helium gas, lead, or sodium. All use depleted uranium as a fuel. The main technological challenges are addressed as follows:

• Generation IV technology must address the high-level waste from fission reactions. This waste includes heavy nuclides-actinides such as neptunium, americium, and curium—that remain highly radioactive for tens of thousands of years. The helium-, lead-, and sodium-cooled fast reactors are designed to have closed fuel cycles in which the actinides are separated from the spent fuel and returned to the fission reactors. Supercritical water-cooled reactors are the only one of the six Generation IV technologies that are cooled by water. Supercritical water-cooled reactors are designed to be a thermal reactor in the intermediate term, using enriched UO2 as a fuel with a once-through fuel cycle. However, the ultimate goal is to build them as a fast neutron reactor with full actinide recycling. Very high-temperature gas reactors have an open fuel cycle. They will employ enriched UO2 as a fuel, possibly in the form of pebbles coated with a graphite moderator like those required for PBMR.

• In the longer term, uranium resource availability could also become a limiting factor. Thus, one challenge to long-term, widespread deployment of Generation IV nuclear energy systems is that their fuel cycles must minimize the production of long-lived radioactive wastes while conserving uranium resources.

• Very high-temperature gas reactors, helium- and lead-cooled fast reactors and the molten salt reactor are all designed to generate electricity and also to operate at sufficiently high temperatures to produce hydrogen by thermochemical water cracking. Thermochemical hydrogen production can be achieved at temperatures of less than 900°C, using processes such as the sulfur-iodine cycle in which sulfur dioxide and iodine are added to water, resulting in an exothermic reaction that creates sulfuric acid and hydrogen iodide. At 450°C, the HI decomposes to iodine (which is recycled) and hydrogen. Sulfuric acid decomposes at 850°C, forming sulfur dioxide (which is recycled), water, and oxygen. The only feeds to the process are water and high-temperature heat, typically 900°C, and the only products are hydrogen, oxygen, and low-grade heat. Because of its potential to produce cheap and green hydrogen, VHTR technology has been given high priority by the U.S. DOE in its Next Generation Nuclear Plant (NGNP), which aims to make both electricity and hydrogen at very high levels of efficiency and near zero emissions.

Nuclear Energy Challenges

The main challenges nuclear power development faces in developed countries are economic and political, while the main issues in developing countries are a lack of adequate infrastructure, particularly in the back-end of the fuel cycle, a lack of expertise in nuclear technology and its safety culture, as well as financial issues. Developing countries are more likely to profit from the enhanced and passive safety features of the new generation of reactors, which have a stronger focus on the effective use of intrinsic characteristics, simplified plant design, and easy construction, operation, and maintenance. Public concerns about nuclear safety, national security, nuclear waste, and nonproliferation are also hindering the development of nuclear power. If nuclear power is to contribute in significant ways to meeting future energy demands, these issues, real or perceived, must be addressed.

Nuclear Safety. The International Nuclear Safety Advisory Group (INSAG) has suggested requiring that future nuclear plants be safer by a factor of 10 than the targets set for existing reactors (i.e., targets of 10″5/year for core damage and 10″6/year for large radioactive releases for future plants).[20]

There are four primary goals for safety issues in nuclear energy development:

• The first is reactivity control, which is the process of stopping fission reactions. The lack of reactivity control caused the Chernobyl reactor accident in 1986.

• The second safety goal is to reliably remove decay heat, which is the heat generated by radioactive decay of the fission products that continue to be produced even after fission reactions stop. Decay heat, if not removed, can result in overheating of and damage to the fuel, such as occurred in the Three Mile Island accident in Pennsylvania in March 1979.

• The third goal is to provide multiple barriers to contain the radioactive material. The barriers include the fuel cladding, the reactor vessel, and the containment building.

• The fourth goal is plant safety sufficient to eliminate the need for detailed evacuation plans, emergency equipment, and periodic emergency evacuation drills.

Although statistics comparing the safety of nuclear energy with alternative means of generating electricity show nuclear to be the safest, vast efforts to enhance the safety of advanced Generation III + reactor designs and the revolutionary Generation IV technologies continue. These designs incorporate what are known as passive safety systems. Evolutionary designs explore many avenues to increased safety, including using modern control technology, simplifying safety systems, making use of passive designs, and extending the required response times for safety systems actuation and operator action. One example of an advanced reactor with passive safety systems is the economic simplified boiling-water reactor (ESBWR), which was developed by General Electric from its advanced boiling-water reactor design and is at the preapplication stage for NRC design certification. The Westinghouse AP1000 light-water reactor features advanced passive safety systems with fewer components than conventional PWRs. For example, compared with a conventional 1000-MW PWR, AP1000 has 50% fewer valves, 35% fewer pumps, 80% less pipe, and 85% less cable. The reactor has a modular design that will reduce construction time to as little as three years from the time the concrete is first poured to the time that fuel is loaded into the core.

Table 3 Nuclear power development—key challenges and potential technical responses

| Challenges | Availability of a technological response |

| Safety area eliminate severe core damage | Reactor and nuclear power plant designs based on maximum use of passive safety features |

| Waste management minimize the volume and toxicity of nuclear waste | Multirecycling of most dangerous long-lived radioactive elements in reactors with fast neutron spectrum |

| Nonproliferation furtherance of nonproliferation aims, namely that nuclear materials cannot be easily acquired or readily converted for nonpeaceful purposes | Recycling of fissile materials, together with radioactive minor actinides; integral nuclear fuel cycle without the stockpiling of Pu |

| Resource base increase the resource base more than tenfold | Multirecycling of plutonium in fast reactors |

Table 3 summarizes some key technical challenges and potential technical responses for a potential nuclear power increase in capacity while at the same time improving economic attractiveness.

However, in spite of the evolutionary improvements in safety, support for nuclear power has not increased in Western Europe and North America. One explanation is that, given there have been significant accomplishments in the area of safety, other issues (such as spent fuel and nuclear waste management) have replaced improvement of existing safety features as the greatest challenges to the future development of nuclear power.

Spent fuel and nuclear waste management. Nuclear energy produces both operational and decommissioning wastes, which must be contained and managed. Spent fuel can be safely stored for long periods in water-filled pools or dry facilities, some of which have been in operation for 30 years. Although the volumes of nuclear waste are small compared to waste from other forms of electricity generation, spent fuel and radioactive wastes from nuclear power plants and spent fuel reprocessing—and ultimately from plant decommissioning—still need to be managed safely. For now, most high-level waste from commercial nuclear power is either stored on-site or transported to interim storage sites. In fact, nuclear power is the only energy-producing industry that takes full responsibility for all its waste and figures these costs into its product, which is a key factor in sustainability. Desirable features of innovative nuclear fuel cycles are economic competitiveness; reduction of nuclear waste and the hazards associated with its long-term storage; furtherance of nonproliferation aims, namely that nuclear materials cannot be easily acquired or readily converted for nonpeaceful purposes; and improved efficiency in resource use. Table 4 gives examples of recent work in innovative nuclear fuel cycles. Although no large-scale programs on innovative nuclear fuel cycles are being implemented at present, some countries are investigating the necessary steps for change in the current situation.

Experience with both storage and transport over half a century clearly shows that there is no technical problem in managing civil nuclear waste sans environmental impact. Shortage of capacity for spent fuel storage is today’s eminent issue in several countries where long-term waste disposal policy remains unsettled. The greatest concern over the storage of high-level nuclear waste is that over such a long period of time, the containers in which waste is stored could eventually leak. However, the scientific and technical communities generally feel confident that technical solutions for spent fuel and nuclear waste conditioning and disposal already exist. The question has become politicized and focused on final disposal because high-level nuclear waste must be stored for thousands of years, but there is general consensus that geologic disposal of spent fuel or high-level radioactive waste from reprocessing can be carried out safely in stable, deep geologic formations. However, site selection remains a major political issue in most countries developing such facilities, and no such commercial facility has yet been authorized. Although most nations have identified potential underground storage sites and conducted geological and geophysical tests as to their suitability, no underground storage site has progressed beyond the planning stage. In the United States, which is perhaps the most advanced in the planning stage, President Bush authorized the construction of a nuclear waste repository at Yucca Mountain in Nevada in 2002.

Regardless of whether particular wastes remain a problem for centuries, millennia, or forever, there is a clear need to address the question of their safe disposal. Therefore, technological breakthroughs over a range of reactors and a range of reactor characteristics are now needed to cope with emerging issues, such as nonproli-feration, environmental mitigation, economics, and enhanced safety and security needs.

ALTERNATIVE ENERGY PROSPECTS

It has been less than 100 years since fossil fuels became the predominant sources of energy in the world with the discovery of oil, the development of natural gas fields, and the widespread distribution of electricity from coal-powered central power plants. From the dawn of human civilization until about 100 years ago, human and animal muscle and wood, with lesser amounts of solar, wind,hydro, and geothermal power, were the predominant sources of energy used by mankind. Can the renewable resources that sustained early civilization be harvested more cost effectively to meet a significant portion of the much higher demands of today’s society?

| Table 4 Innovative technologies related to nuclear fuel cycle | |||

| Attribute | Process and system | Relevant countries | Features |

| Fuel composition and process | Pyro-process | Japan, Russia, United States | Nuclear waste volume is smaller and process facility is simpler than those of wet process (expected economic and environmental advantages) |

| Vibro-packed fuel | Russia, Switzerland | Fuel particle is directly produced from acid solution from reprocessing (economic merit is expected to compare to powder technology) | |

| DUPIC system | Canada, Rep. of Korea | Plutonium is not separated from PWR spent fuel (proliferation resistance is expected) | |

| Thorium fuel (Th-U, Th-Pu) | India, United States | Th resource is abundant. Fuel with Th-233U composition generates less MA than U-Pu fuel | |

| Inert-matrix fuel | France, Japan, Switzerland | Due to chemically stable oxide, spent fuel is regarded as waste form (environmental mitigation) | |

| Partitioning and transmutation (P-T) system | Accelerator driven system | France, Japan, United States | High neutron energy produced in accelerator destroys MA, LLFP. Sub-critical core enhances safety |

| P-T system with fast reactor (FR) | Japan, Russia | Existing FR technology is applied for destruction of MA, LLFP | |

| Fast reactor and fuel cycle system | Pb (+ Bi) FR | Russia | Enhanced resource utilization, proliferation resistance, safety, and waste features |

Many regions of the world are rich in renewable resources. Winds in the United States contain energy equivalent to 40 times the amount of energy the nation uses. The total sunlight falling on the country is equivalent to 500 times America’s energy demand. And accessible geothermal energy adds up to 15,000 times the national demand.[27] There are, of course, limits to how much of this potential can be used because of competing land uses, competing costs from other energy sources, and limits to the transmission systems needed to bring energy to end users. Moreover, the market penetration potential of renewable energy technologies will face a situation confronting any new technology and institutional constraints that attempt to resist an entrenched technology. But renewable energy technologies have made great progress in cost reduction, increased efficiency, and increased reliability in the past 30 years, as well as increasing contributions to the world’s energy supply. In 2000, the global electricity capacity generated by renewable energy sources accounted for about 30% (102 GW) of the total electric power capacity (see Table 5).[2] Most of this energy came from hydroelectric power. However, other nonhydro renewable energy resources such as biomass, alcohol fuel, wind, geother-mal, and solar energies have increased due to technological innovations and cost reductions and are becoming viable, commercially competitive, and environmentally preferable alternatives to traditional fossil fuels. While the global resources of fossil fuels gradually decline and environmental concerns associated with fossil fuels increase, the benefits of renewable energy are undeniably attractive.

Renewable energy sources have historically had a difficult time breaking into the existing markets dominated by traditional, large-scale, fossil fuel-based systems. This is partly because renewable and other new energy technologies are only now being mass-produced and have previously had high capital costs relative to more conventional sources because fossil fuel-based power systems have benefited from a range of subsidies, cheap raw materials, mass volume production over a span of many years, and a mature infrastructure. Moreover, the alternative energy sector has lacked appeal to investors in the United States because of heavy regulation, low growth, long-time return, and lack of support for innovative new companies in established energy markets.

The push to develop renewable and other clean energy technologies is no longer being driven solely by environmental concerns. Rather, these technologies are now also becoming economically competitive (Fig. 4). With continued research and deployment, many renewable-energy technologies are expected to continue their steep reductions in cost for such programs as wind, solar thermal, and photovoltaic energy. Several could become competitive over the next decade or two, either directly or in distributed utilities. Wind turbines, in particular, could even become broadly competitive with gas-fired combined-cycle systems within the next ten years in places where there are winds of medium or high quality. One disadvantage of renewable energy systems has been the intermittent nature of some sources, such as wind and solar energy. But this problem is not insurmountable—one solution is to develop diversified systems that maximize the contribution of renewable energy sources to meet daily needs, but also to use clean natural gas and/or biomass-based power generation to provide base-load power for the peak times in energy use, such as evening air conditioning or heating demand. Because of the changing U.S. electricity marketplace, remote or distributed markets for renewable electricity, as discussed above, appear to be more promising today than centralized electricity markets. Renewable energy sources are pinning their hopes on breakthroughs in the development of small, stationary and portable fuel cells and on the fast growing market for them as minipower plants for use in factories, offices, retail stores, homes, and automobiles.

Table 5 Renewable grid-based electricity generation capacity installed as of 2000

| Technology | All countries (MW) | Developing countries (MW) |

| Total world electric power capacity | 3400,000 | 150,000 |

| Large hydropower | 680,000 | 260,000 |

| Small hydropower | 43,000 | 25,000 |

| Biomass power | 32,000 | 17,000 |

| Wind power | 18,000 | 1,700 |

| Geothermal power | 8,500 | 3,900 |

| Solar thermal power | 350 | 0 |

| Solar photovoltaic power (grid) | 250 | 0 |

| Total renewable power capacity | 102,000 | 48,000 |

Fig. 4 The renewable electricity cost.

However, despite the significant benefits of alternative energy sources, according to the recent AEO2004 forecast, which assumes the world’s oil supply peak will not occur before 2025, petroleum products are predicted to dominate energy use in the transportation sector. Energy demand for transportation is projected to grow from 26.8 quadrillion Btu in 2002 to 41.2 quadrillion Btu in 2025 (Fig. 5).

According to the forecast, motor gasoline use will increase by 1.8% per year from 2002 to 2025, when it will make up to 60% of transportation energy use. Alternative fuels are projected to displace only 136,800 barrels of oil equivalent per day in 2010 and 166,500 barrels per day in 2025 (2.1% of light-duty vehicle fuel consumption) in response to current environmental and energy legislation intended to reduce oil use. Gasoline’s share of the demand is expected to be sustained by low gasoline prices and slower fuel efficiency gains for conventional light-duty vehicles (cars, vans, pickup trucks, and sport utility vehicles) than were achieved during the 1980s.

Therefore, even though renewable energy technologies have advanced dramatically during the past 30 years, fossil fuels seem slated to dominate the energy supply, and oil will remain the world’s foremost source of primary energy consumption throughout the 2001-2025 period (at 39%) despite expectations that countries in many parts of the world will be switching from oil to natural gas and other fuels for their electricity generation. Robust growth in transportation energy use—overwhelmingly fueled by petroleum products—is expected to continue over the 24-year forecast period as shown in Fig. 6.[19] For this reason, oil is projected to retain its predominance in the global energy mix, notwithstanding increases in the penetration of new technologies, such as hydrogen-fueled vehicles.

The same trend of fossil fuel dominance over a slowly growing market in renewable energy can be found in the United States in the past five years. Renewable energy consumption in 2003 grew only 3% to 6.1 quadrillion Btu.[26] Overall, renewable energy contributed only 6% of the nation’s total energy supply. Current levels of renewable energy use represent only a tiny fraction of what could be developed, but the U.S. energy infrastructure is mainly based on the consumption of fossil fuels. As shown in Fig. 7, solar and wind only accounted for 3% of total renewable energy use in 2003—less than 0.2% of the U.S. energy supply. Without government policies or programs—such as environmental laws aimed at limiting or reducing pollutants from the combustion of fossil fuel consumption and encouraging the use of nonfossil fuels— consumption of fossil fuels like oil, natural gas, and coal are expected to supply most of the primary energy needed to meet the projected demand for end-use consumption.

In 2001, the U.S. DOE produced a 50-year perspective for future U.S. Highway Energy Use.[4] The DOE assumed the demand for world oil products would grow at 2% per year. After 2020, when conventional oil production is assumed to peak—once 50% of ultimate resources have been produced and begin a continual decline—the gap between continuing demand growth and declining production could be around the equivalent of 50 billion barrels of oil (145 MBPD) by 2050, or almost twice the current conventional oil production. Although there is considerable uncertainty, the report suggested that the United States should start transportation’s energy transition immediately because the time needed to fully implement a new vehicle technology in all vehicles on the road will be 30 years or more, and fully implementing a new fuel will take even longer.

Fig. 5 Transportation energy consumption by fuel (quads).

Fig. 6 World marketed energy consumption by energy source, 1970-2025.

Fig. 7 Renewable energy consumption in the U.S.’s energy supply, 2003.

The market penetration of alternative renewable fuels, such as biofuel/biodiesel or hydrogen (see Table 6), are dependent on their cost-effective production, storage, delivery, safety, and customer acceptance, as well as related vehicle technology development, such as HEVs, battery-electric vehicles, and fuel cells.

Obviously, the transition to energy diversity with significant proportions of renewable energy and nuclear energy will change the world’s use of energy, its economy, and the environment. A recent study on the costs and benefits of gradually increasing the share of the nation’s electricity from wind, biomass, geothermal and solar energy, as proposed in renewable portfolio standards (RPS), range from a 4% reduction in carbon dioxide emissions in 2010 to a 20% reduction in 2020, which would freeze electricity-sector carbon dioxide emissions at year 2000 levels through 2020 at a modest cost of $18 per ton reduced.[27] In particular, the plains, western, and mid-Atlantic states are projected to generate more than 20% of their electricity from a diverse mix of renewable energy technologies. By contrast, carbon dioxide emissions are projected to grow 24% over the same period under a business-as-usual scenario. Renewable energy and energy efficiency are not only affordable, but their expanded use will also open new areas of innovation and business, creating opportunities and a fair marketplace for the transition to a clean energy economy, all of which will require leadership and vision from both government and industry. However, in the absence of government policies for both technology push and market pull, those renewable energy technologies will be not widely commercialized, and it will be difficult to extend the use of renewable sources on a large scale because most renewable energy sources are not expected to compete economically with fossil fuels in the mid-term if there are no significant changes in the cheaply-priced fossil fuel market.

CONCLUSIONS

Over the past 30 years, renewable energy technologies with unique environmental and social benefits have made significant progress as alternative energy options to fossil fuels. Of the many alternative sustainable energy technologies that have been developed, some are already making large inroads into the marketplace, such as nuclear power, biomass, hydropower, geothermal, wind, and solar power. Other technologies, perhaps those most beneficial to a sustainable future, require more efforts in research, development, and deployment before they can become economically viable and technically feasible. The recent rise in demand for energy, which is mostly due to increased demand in China and India as part of the expansion of their modern economy, coupled with the geopolitical aspects of the energy sector, has caused record high oil and gas prices across the globe. To confront the limited availability of what has been thus far viewed as inexpensive fossil fuels and growing energy demand from developing countries, the world is now necessarily on the brink of an energy transition from fossil fuels to clean renewable energy sources. However, the global energy infrastructure is mainly based on the consumption of fossil fuels, with very little being done to reduce dependence on these energy resources until now. Although after three decades of development, renewable energy has been proven technically and economically feasible, the timing of the transition will depend on government polices and the will of the customer. For example, current nuclear energy is technically and economically feasible to meet market demand, but certain social and safety issues remain that need to be addressed through a collaborative approach of the world community. The recently rising prices of conventional sources of energy give the strongest economic argument in favor of the expanded market of renewable energy sooner rather than later. The evolution of any new energy technology will take a long time (more than 20 years) to be well accepted and established in the market. Energy substitution will begin in earnest when the costs of energy production by alternative methods are lower than the prevailing prices of conventional sources and when consumers are convinced there will be no reversal in price and supply trends. Although greater energy utilization efficiencies have proven to be effective conservation options in reducing energy consumption over past decades, they cannot and should not be viewed as an ultimate remedy or solution. In the long run, renewable energy and advanced nuclear energy seem to be the best options for meeting the increasing clean energy demand.

Table 6 Comparisons of gasoline and alternative transport fuels

Table 6 Comparisons of gasoline and alternative transport fuels (Continued)