ABSTRACT

Synthetic soft polymer gels have many advantages over protein-based gels that are derived from animal collagen and bones such as stability at room temperature and prolonged shelf life. In addition, the ability to tailor the formulations and processes of synthetic gel to control mechanical properties both isotropically or anisotropically is another essential feature in order for gels to mimic the spectrum of biological tissues. However, it is impractical to physically characterize all aspects of every gel available. To do so would require production of a significant amount of material to accommodate all the varying tests needed for a comprehensive study. A novel punch test was developed as a simple solution to obtain mechanical responses at different loading rates without the production of a large amount of sample material. The gels used in this effort are 10% and 20% ballistic gelatin, the commercially marketed PermaGel™, and triblock copolymer gels. The experimental setup is discussed, and the results are presented and compared to a previous study that discussed the tensile behavior of these soft materials.

INTRODUCTION

Traditionally, ballistic gelatin is used extensively to examine the penetration depth of firearms. While useful as a base material for qualitative comparison, the applications of this biologically derived gelatin become very limited when used as a tissue simulant for quantitative testing. Next generation armor and protection systems require an understanding of injury mechanisms that has not yet been realized [1-3]. However, ballistic gelatins inconsistent viscoelastic properties, high sensitivity to temperature, and aging effects all prove detrimental to producing data to validate proposed material models [4]. Synthetic gelatins are therefore a promising solution because networks of cross-links and polymer chains can be tuned to resemble the mechanics of biological tissues. Unfortunately, such a wide range of controllable properties necessitates laborious and repetitive testing for full characterization.

Much prior work has been performed on soft tissue stimulants. Methods have been established in constrained and unconstrained compression at a variety of strain rates [2,5,6]. Often this work is to measure a shear modulus for use in various constitutive models. While existing models can be useful at determining material response at lower rates of strain, a fully nonlinear model is required at higher rates [7]. Wu et al. [6] also demonstrated that friction can cause a non-uniform deformation state in unconfined compression tests which contradicts assumptions in traditional models. In a study on the effects of temperature, aging time, and strain rate to the penetration depth of ballistic gel, Cronin and Falzon [4] found that tensile strain dominates over shear strain during failure. This also contradicts many current models of tissues that are based on shear failure criteria. Microscale indentation and rheology tests have been performed, proving that viscoelastic and hyperelastic models are applicable at small (physiological) deformations, but large strain behavior of nonlinear tissues warrants further analysis [8-11]. Other methods of modeling human tissue behavior involve porcine, bovine, rat or mouse tissue. Snedeker et al. [8] performed impact experiments on porcine and human kidneys, and found large differences in stress to failure. Fracture tear tests have also found basic energy dissipation and tear resistance values [12]. Moy et al. [13,14] have used digital image correlation techniques to measure strain field qualities in notched gelatin tensile specimens. This technique provided a measurement of the maximum tensile strain and energy required for a crack to propagate through gelatin.

This interest led to the development of a simple punch penetration test to screen the multitude of possible gelatin formulations into a smaller group of gels that resemble the mechanical behaviors of ordnance gelatins. Various gelatin materials were subjected to a constant-rate displacement by a 6.35 mm hemispherical penetrator tip. These materials included synthetic polymer gels, ballistic gels, and Permagel™, a commercially available ballistic gel replacement. Then puncture data was compared to gelatin fracture tear data from Moy et al. [13] to ensure that the basic puncture test can be used as a screening process to find suitable tissue surrogates without an in-depth investigation into each material.

Materials

Three different synthetic polymer gels were made from different concentrations of Poly(styrene-b-ethylene-co-butylene-b-styrene) (SEBS) G1652 as-received from Kraton Polymers (Houston, TX, USA) and mineral oil as-received from Aldrich Chemical (Milwaukee, WI, USA). These three gels were mixed in sheets with concentrations of 70, 80, and 90 percent mineral oil to SEBS polymer. Ballistic gelatin was made from Bloom 250 Type A ordnance gelatin mix as-received from GELITA USA (Sioux City, IA). Each batch was mixed in water according to manufacturer directions, poured into a sheet, refrigerated at 3.89°C, and tested the following day. The two types of ballistic gel typically used for bullet penetration testing are either 10 or 20 percent by mass gelatin, and both are accounted for in this work [4]. Permagel™ is a transparent material designed to have similar properties to 10% ballistic gelatin, but without its inherent disadvantages. The material was used as-delivered from USALCO (Browns Mills, NJ) and was cut from a large base block, molded into sheets and allowed to cool before testing. The group of gelatins tested is included in Table 1.

Table 1: Collection of Materials Tested

|

Material |

Concentration |

Source |

|

Mineral Oil/SEBS polymer |

70/30 80/20 90/10 |

Aldrich Chemical/ Kraton Polymers |

|

Permagel |

N/A |

USALCO |

|

Bloom 250A Ordnance Gel |

(by weight to water) 10% 20% |

GELITA, USA |

Test Methods

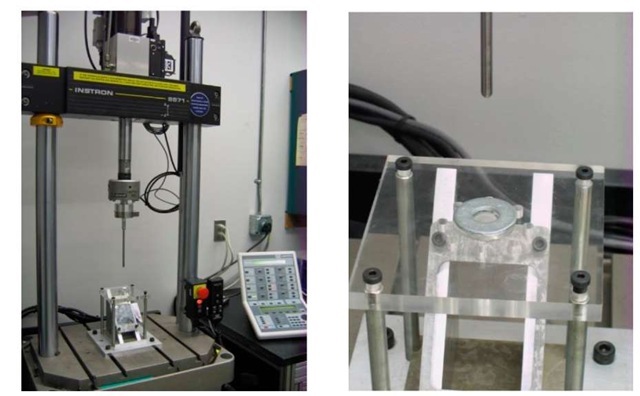

A 4mm thick specimen was bonded to one side of a standard 7/16 inch washer, excess material was trimmed and the specimen was tested to full failure with a 6.35 mm hemispherical indenter. All specimens were inspected for bubbles or debris prior to gluing. An elevated acrylic table fixture was used to provide clearance for full specimen failure and give ample space for observation. A custom 45° triangle mirror fixture was then designed to fit underneath the elevated fixture to observe the specimen during the indentation. Figure 1 shows the test fixture. After the specimens fully adhered to the washer, the entire sample was placed on the top of the fixture centered over the middle 12.7 mm diameter hole in the acrylic plate. While the washer did not provide clamping pressure by any means, it did give an open space on the top gelatin surface to fill with lubricant. Friction between the acrylic and the gelatin provided ample resistance to prevent any slippage during the experiment.

Figure 1: Punch Test Fixture with 45° Mirror

An Instron 8871 servo-hydraulic load frame was used to control and directly measure the load and displacement required to indent and to puncture the gel specimens. Three different displacement rates were addressed: 12.7, 127 and 1270 mm/min. These gave a wide range of material characteristics while remaining within the capabilities of the load frame. The overall machine setup is in Figure 2. Lubrication was used in order to minimize friction between the gel and indenter. For ballistics gel an olive oil was used, but silicone oil of similar viscosity was used for the Permagel™ and synthetic polymer gels, to ensure the lubricant did not affect the gel material being tested. Prior to each experiment, the indenter was lowered until it just contacted the gelatin surface.

Figure 2: Machine Setup with Accompanied Gel Punch Fixture

RESULTS AND DISCUSSION

Without lubrication, friction between the indenter and the gelatin was quite evident in the preliminary testing. It was observed that when oil was omitted specimens would exhibit a "cork" type failure characteristic of a shearing failure instead of the desired Mode I tearing failure. Load and displacement data obtained for all experiments at each extension rate can be seen in Figures 3a through c. Figures 4a to 4c provides a magnified view of the gels at the lower load range. This data includes all testing, and it is clear from the amount of overlap that the test is inherently repeatable. The gelatins displayed a close agreement between certain pairs of material, such as the close agreement between 80/20 and Permagel™ for all three rates. However, ballistic gels do not exhibit the relaxation portion of the load-displacement curve that the other 4 materials expressed around 8 mm displacement. This can clearly be seen in the 1270 mm/min data where the 20% ballistic gel deviates from 70/30 data curve at around 7.5 mm extension. Note that prior to this point there is a close agreement between the 20% ballistic gel and 70/30 curves. The ballistic gels also show lower overall extensions than the other materials. When the 10% ballistic and Permagel™ gelatins are compared across the three rates studied, the load response converges as the displacement rate increases. This compels the idea that Permagel™ could be used as a replacement for the 10% ballistic gelatin, but only at higher rates.

Figure 3: Load vs. Extension for all Gel Materials Tested at (a) 12.7 mm/min, (b) 127 mm/min, and (c) 1270 mm/min Displacement Rate

Figure 4: Expanded Load vs. Extension for Punch Experiments at the Lower Load Region at (a) 12.7 mm/min, (b) 127 mm/min, and (c) 1270 mm/min Displacement Rate

The maximum displacement to failure was compared in Figure 5 across the three displacement rates of 12.7, 127, and 1270 mm/min. Two distinct trends are clear. Most interesting is the distinct difference in trend between the mineral oil and the Permagel™/ballistic gel. The synthetic mineral oil gels exhibit a much larger stretch ratio than the ballistic gelatins or Permagel™ at a higher rate of displacement, which suggests a different strengthening mechanism may occur at these higher displacement velocities. This could easily be attributed to the structure of polymer chains and amount of crosslinking in the mineral oil gelatins which do not occur in the others. As the manufacturer claims Permagel™ is similar to the ballistic gels but requires a larger overall extension to fully penetrate, which is shown from the data at all rates of displacement.

Figure 5: Maximum Extension as a Function of Displacement Rate for all Gel Punch Experiments

A similar analysis was performed with the maximum load to failure in Figure 6. The 80/20 formulation ratio of mineral oil to SEBS polymer closely agrees with the Permagel™ at all displacement rates studied. Unlike the 70/30 gelatin which gave a much larger penetration resistance. Despite a similarity in extension to failure between the 70/30 and Permagel™ at lower displacement rates, the punch test showed a vast difference in stiffness of the 70/30 gelatin. While miniscule, the loads of the 90/10 polymer gel resemble the 10% ballistic gel across all displacement rates.

Figure 6: Maximum Load as a Function of Displacement Rate for all Gel Punch Experiments

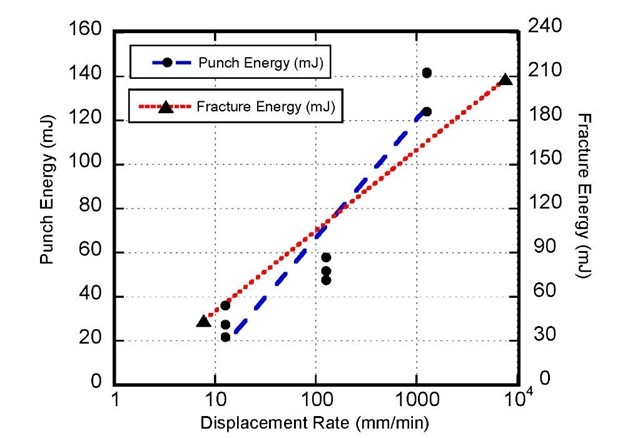

Each load-extension curve was integrated to determine the overall energy required to fully puncture the gelatin. These values were then correlated to a prior work by Moy et al. which tested the fracture characteristics of both ballistic gel concentrations, and Permagel™ [13]. A Mode I test was used with a dogbone shaped specimen that had a small pre-crack. The crack propagation was then inspected using high speed cameras with DIC to acquire surface strains near and around the crack tip. The load-extension curve was also integrated to obtain fracture energy values. This comparison is shown in Figure 7 a, b, and c. It is important to note the difference in scaling between the two data sets, for they are not in perfect alignment in any case. However, considering the differences between the two test methods, the results are quite similar in trend. It is very easy to see the agreement in the 20% ballistic gel for example, where the fracture energy is close to a factor of 5x higher than the punch energy. This comparison validates the punch method presented here as a simple screening process as it is a much less demanding test.

Figure 7a: Comparison between Punch Energies and Fracture Energies for Permagel™

Figure 7b: Comparison between Punch Energies and Fracture Energies for 10% Ballistic Gel

Figure 7c: Comparison between Punch Energies and Fracture Energies for 20% Ballistic Gel

CONCLUSIONS

A significant number of synthetic gelatins offers multiple solutions for potential replacement of ballistic gelatin. More importantly, polymer gels can be tailored to have characteristics to actual biological tissues. To adequately examine the load response of every gel available would be very demanding. In an effort to find a suitable tissue surrogate to validate theoretical models for next-generation armor and protection systems, several gelatin materials were compared in a simplified puncture test. Ballistic gels, mineral oil gels, and the commercially available Permagel™ were punctured to full failure using a hemispherical indenter across extension rates of 12.7, 127 and 1270 mm/min. Similar initial load responses were seen in the 10% ballistic, 80/20 mineral oil/SEBS, and Permagel™ at each rate despite the ballistic gelatins lower extension and maximum load to failure. Through a comparison with previous mode I gel fracture data, the punch technique provides an easy screening method to classify a gelatin as a possible tissue simulant.