Granite

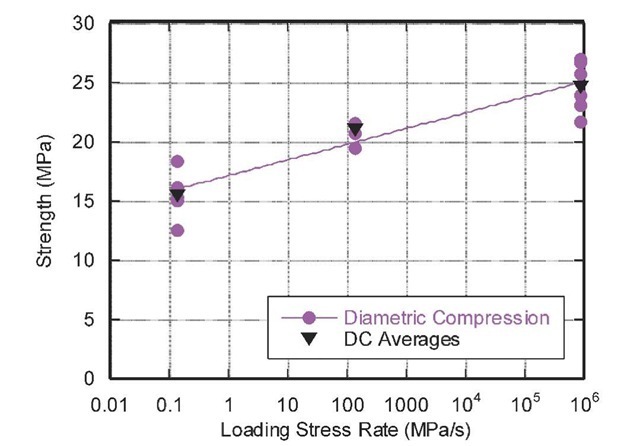

The tensile strength of the granite samples was evaluated at the low, intermediate and high loading rates using the diametric compression technique. These results are presented in figure 11. At low rate the mean tensile strength was approximately 15MPa. This increased to approximately 21MPa for the intermediate loading rate and to 22.5MPa at high rate. These values are substantially higher than those for the SAM35 concrete and mortar samples and is due to the strong crystalline microstructure of the granite. The increase in tensile strength with loading rate was more pronounced over the low to intermediate rate range, which is in contrast to the mortar response where the increase was only seen over the intermediate to high rate range. Combining these two responses, we would expect a fairly linear increase over low to intermediate to high rate. This is exhibited in the behaviour of the SAM35 concrete which is a composite of these two representative components.

Figure 11: Granite tensile strength versus loading stress rate

The high strength glue used for the SAM35 concrete and mortar direct tension tests was not strong enough for the granite so no high rate direct tension tests could be performed for this material. Thus there is no comparison between the two test techniques for this material.

Alcatraz concrete

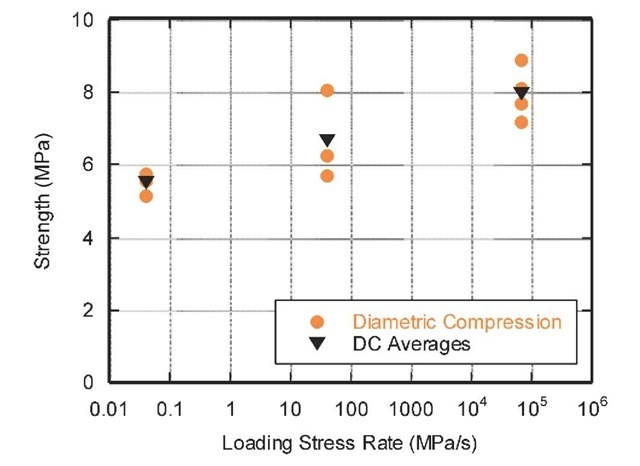

The concrete sample obtained from the Alcatraz prison in San Francisco was tested at the three loading rates in diametric compression and its tensile strength results are presented in figure 12. The material response was similar to that of the SAM35 concrete. It showed an increase in tensile strength with loading rate, which was fairly linear over the range tested. The mean tensile strength at low rate was approximately 5.5MPa, increased to 6.6MPa at the intermediate loading rate and to approximately 8MPa at the high loading rate. The Alcatraz concrete was stronger than the SAM35 concrete, however, the SAM35 concrete is a relatively low strength concrete with only 3500psi or 24MPa quasi-static compressive strength.

Figure 12: Alcatraz concrete tensile strength versus loading stress rate

Ultra-high performance concrete

The tensile strength results for the Ultra-High Performance (UHP) concrete, tested at the three loading rates in diametric compression, are shown in figure 13. The UHP concrete was substantially stronger than the other concretes tested, with tensile fracture strengths similar to that of the granite. The mean tensile strength at low rate was approximately 15.5MPa, this increased 21MPa at the intermediate loading rate and to 24.5MPa at the high rate. Thus, similar to the granite, the increase in tensile strength with loading rate was more pronounced for the low to intermediate loading rate.

Figure 13: Ultra high performance concrete tensile strength versus loading stress rate

As discussed earlier, the UHP concrete contains short steel fibers of length 12.7mm and diameter 0.2mm, which are randomly distributed throughout the concrete at 6.2% by weight. In work by Williams, et al [18], a similar steel fibre reinforced high strength concrete material, Cor-Tuf, was tested at low strain rate in direct tension both with and without the fibers. They observed a slightly lower peak stress in the material containing the fibers, which suggests that the steel fibers are not contributing to increase the peak tensile strength (rather the opposite). The lower strength is presumably because of the failure initiation at the weak interfaces introduced between the steel fibers and the concrete. However, the benefit of the steel fibres is assumably in their ability to increase the tensile post peak load bearing capacity (the ‘ductility’) of the material. This is evident by the condition of the samples after the tests reported here. Whereas the other materials investigated fractured into several pieces, typical of a brittle material response, the UHP concrete fragments stayed held together by the steel fibres, maintaining some residual strength in the sample.

Isaacs, et al [1] also found a sustained load bearing post peak response for the UHP concrete, which they attributed to the steel reinforcing fibers. They conducted preliminary tests on the UHP concrete at high strain rate (approximately 100s-1) using a direct tension SHPB. They conducted two tests on 76.2mm diameter specimens which were notched to 57.2mm diameter. The samples were glued to the input/output bars using epoxy and the notch was required to reduce the concrete cross section area to prevent failure at the glue line (as the UHPC tensile strength is higher than available epoxies). They reported peak stresses of 16.6Mpa and 15.4MPa for the two tests. This is lower than the mean peak tensile strength of 24.7MPa at high rate reported here. This discrpeancy is due to the difference in test methodologies. The notched specimen used by Isaac, et al creates a stress concentration at the notch and so the peak stress is less than true tensile strength of the material. Whereas for the tests results reported here, the diametric compression test produces a biaxial stress state and so the induced tensile region is not pure uniaxial tension. The difference in specimen size, which affects the lateral interia and confinement in the sample, may also play a role. Finally, the tensile strain rate for the tests reported here was probably lower, although it has been shown here that the strength decreases with decreasing strain rate.

DISCUSSION

A summary of the diametric compression results (mean values) for the five materials is shown in figure 14. This shows an increase in tensile strength with loading rate for all of the materials tested. For the mortar the increase only occurred from the intermediate to high loading rates, whereas for the granite the increase was most significant at the low to intermediate loading rates. For the SAM35 and Alcatraz concretes, which are both combinations of these two representative components, the response was a combination of these individual material responses, where the tensile strength increased fairly linearly over the total loading rate range investigated. The Alcatraz concrete was stronger than the SAM35 concrete, however, the rate of increase in tensile strength with loading rate was similar for both concretes, as shown in figure 14, where the two lines are parallel. The UHP concrete was substantially stronger than the other concretes tested, with a similar tensile strength to the granite. However, the failure response of the UHPC was much less brittle compared to the granite. The UHP concrete exhibited post fracture residual load bearing capacity due to the steel reinforcing fibres, which has also been reported by other researchers [1,18].

Figure 14: Summary of average tensile strength versus loading stress rate for the five materials tested

The material rate sensitivity for the five materials was reported using the loading stress rate. It is recognized that most rate dependent numerical model models require the material strength as a function of strain rate, not stress rate. However, it is difficult to determine the tensile strain and corresponding tensile strain rate using the diametric compression technique. The DIC technique was attempted, however, was not successful here due to the small strains in concrete before failure. The high-speed camera was setup to image the entire sample surface. It is possible that the DIC technique could be successful by zooming in on the sample center and using a smaller speckle size to improve resolution and provide greater strain measurement sensitivity. This was not pursued here. The DIC technique has been successfully used for measuring the tensile strain in diametric compression tests by [9], however, the material tested (polymer bonded sugar explosive stimulant) most likely produced larger strains than those seen in concrete.

It is also to possible to convert from stress rate to strain rate through the elastic modulus of the material; however, the modulus is usually obtained from quasi-static experiments and may also be rate dependent. Consequently, this conversion has not been performed here and the material tensile strength is maintained as a function of stress rate.

The experimental results presented in figures 8, 9, 11-13 show significant scatter and this is a consequence of the heterogeneous nature of many of the materials tested. This results from the aggregate components in the concrete and the steel fibers in the UHP concrete. The specimen sizes used here (20mm & 25.4mm diameter) were relatively small; this was influenced by the available experimental apparatus, specifically, the diameter of the split Hopkinson pressure bars used for high rate testing. The Australian standard for quasi-static concrete testing [7] specifies specimen size requirements relative to aggregate size and recommends 150mm diameter samples where the aggregate is less than 40mm and 100mm diameter samples where the aggregate is less than 20mm.The Defense Science and Technology Organization (DSTO) in Australia are currently building a 100mm diameter split Hopkinson pressure bar system, capable of testing concrete in both direct tension and compression. Thus, high rate material characterization of larger sized concrete specimens will be the subject of continuing future work.

The limited comparison between the diametric compression and direct tension test techniques performed here at high rate suggests that the agreement between the two techniques is material dependent. However, more materials need to be tested to confirm this. The different test techniques produce different stress states and so it is feasible that while one material might behave similarly under the two stress states, another material might have a different response for each stress state. The comparison for the SAM35 concrete was very good, whereas the results differed for the mortar. However, the diametric compression technique enables an estimation of the tensile response of high strength brittle materials, such as granite and the ultra-high strength concrete, which would be very difficult to test otherwise in direct tension. It also permits the use of more common compression test apparatus, particularly in the case of high rate testing using a split Hopkinson pressure bar.

CONCLUSIONS

The tensile strength for various concretes and their representative constituent components was determined at three loading rates using the diametric compression (Brazilian/ split-tension) technique. All five materials tested showed an increase in tensile strength with increasing loading rate.

Direct tension tests at high loading rate were also performed for several of the materials. The diametric compression and direct tension test techniques produce different stress states and agreement between the two methods appears to be material dependent. However, this finding is preliminary and more tests are required to confirm this.

The diametric compression test remains a useful technique. It enables tensile testing of high strength brittle materials, such as granite and ultra-high performance concrete, which are very difficult to test otherwise in direct tension. However the diametric compression technique does not provide any information on the post fracture response of the material, which is important for materials such as the ultra-high performance concrete. This requires direct tension testing.