1.9. Vehicle Assemblies

The main components of an automobile can be sub-grouped in the following assemblies

(Chart 1.2)

(i) Engine or power plant

(») Running gear or basic structure

(Hi) Driving system

(iv) Basic Control system

(v) Electrical system

(ui) Accessories

Engine. The prime movers used in almost all vehicles are either gasoline (petrol) or diesel

engines. Some speciality automobiles use a different type of engine. The diesel engine consumes

considerably less fuel than the gasoline engine, when operated at low speeds. The rotating

combustion chamber engine is gaining popularity in small cars, and its use will probably

increase. Turbine engines show promise, especially in commercial vehicles. They are powerful,

light weight and produce less hydrocarbons and carbon monoxides. They are ideally suited to

replace diesel engines in over-the-road load carrying vehicles. Battery or electric vehicles are

also being introduced to conserve fossil fuels and to minimise pollution.

The engine is located either in the front, mid-ship or rear. Front mounted engines are more

common in automobiles. The engine contains mechanical parts, fuel system, cooling system,

lubricating system and exhaust system. Figure 1.21 shows an automobile engine with its clutch

and gearbox. The radiator is located at the front of the engine.

Thinning Gear. The running gear comprises of the frame, suspension, springs, shock

absorbers, wheels, rims and tyres. The tyres are the only place where the automobile touches

the road. All of the engine power, steering and braking forces must operate through these tyre-to

road contact areas. Control of the vehicle is reduced or lost when the tyre does not contact the

road or when skidding begins.

The suspension keeps the tyre in contact with the road as much as possible in all road

conditions. The suspension system must be strong enough to resist axle twisting from high

engine power and from brake reaction. The suspension system consists of springs, shock

absorbers and linkages or arms.

Fig. 1.21. An automobile engine with clutch and gearbox.

The frame is a rigid structure that forms a skeleton to hold all the major units together. The

wheels and tyre assemblies support the frame and the units are attached to it, through front

and rear suspension systems so as to follow the road irregularities.

Driving System. The driving system comprises of the clutch, transmission, driveline,

differential and rear axle. The driving system carries power to the driving wheels from the

engine. A clutch or torque converter is connected to the engine crankshaft to effectively

disconnect or connect the engine with the driveline. *

The function of the transmission is to provide gear reduction, which produces high torque

to start the automobile from rest and drive it up the steep grades. It also provides a reverse gear

for backing the automobile. A propeller shaft is required to transmit the engine power to the

rear axle. It has universal joints on each end to provide flexibility as the suspension position

changes. A differential incorporated with a rear axle, splits the incoming power to each drive

wheel. This also allows the drive wheels to turn at different speeds as they go over bumps and

round corners.

Control System. The steering and braking systems form the basic control system. The

steering gear controls the direction in which the front wheels are pointed. The steering systems

have some parts (i.e. the steering gear) bolted to the frame, some parts (i.e. the steering column)

bolted to the body and some parts closely integrated with the front suspension system.

The brake system slows down the speed of the vehicle or stops it at the driver’s will. The

entire brake system is located in the chassis. The brakes are mounted inside the wheels. The

brake designs are either drum type or disc type. Four-wheel disc brakes are more common in

use.

Electrical System. The electrical system is a part of both chassis and body. The system

includes the starting, charging, ignition, lighting and horn circuit. Some electrical circuits are

for engine operation, some for power transmission and others for lighting and operation of

protective devices and accessories.

Accessories. Accessories are used to make driving more pleasant. They include car heater,

air-conditioner, radio, windscreen wiper, indicators etc.

1.9.1. Engine Position

Front Engine. There are a number of reasons for locating the engine at the front of a car

as shown in Fig. 1.22. The large mass of an engine at the front of the car provides the driver

protection in the event of a head-on collision, and engine-cooling system becomes simpler.

Also the cornering ability of a vehicle becomes better due to concentration of weight at the front.

Fig. 1.22. Front-engined car.

Rear Engine. With the engines mounted at

the rear of the vehicle the components like the

clutch, gearbox and final drive assembly can be

installed as a single unit. This arrangement re-

quires the use of some form of independent rear

suspension. Rear-engine layout is mostly con-

fined to small cars, as this adversely effects on the

“handling* of the car. Also it takes up a larger

space in comparison to the front-engined car for

carrying luggage. However, a rear-engined layout

increases the load on the rear driving wheels, providing better grip on the road. Figure 1.23

presents one of the rear-engined cars. The front seats are close to the front wheels than a

front-engined car, and the floor is quite flat.

Central and Mid-engine. This engine location is generally confined to sports cars because

this provides both good handling and maximum traction from the driving wheels. This arran-

gement, however, is not convenient for everyday cars as the engine takes up space that is

Fig. 1.23. Rear-engined car.

normally occupied by passengers. The mid-

engine layout, shown in Fig. 1.24, combines

the engine and transmission components in

one unit.

1.9.2. Drive Arrangements

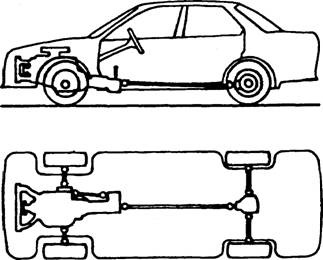

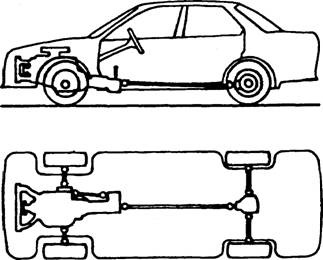

Rear-wheel Drive. In this layout (Fig.

1.25) the rear wheels act as the driving

wheels and the front wheels swivel for steer- .

ing of the vehicle. The location of the main

components in this arrangement makes each unit accessible. A major drawback is the protrusion

of the transmission components into the passenger compartment due to which a larger bulge is

produced in the region of the gearbox and a raised long tunnel down to the centre of the car floor

is formed to accommodate the propeller shaft.

In this driving arragement, the load transfer takes place from the front to rear of the vehicle

during hill climbing or acceleration providing good traction. However, if the wheels lose

adhesion, the driving wheels move the rear of the car sideways causing the car to ‘snake’.

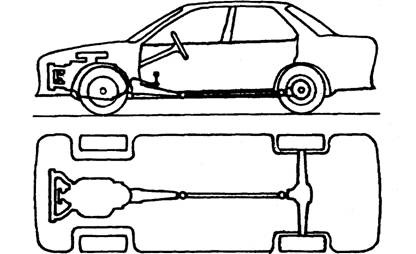

Front-wheel Drive. This layout (Fig. 1.26) is compact as the engine is mounted transver-

sely and hence very popular for use on cars. From space considerations the length of the engine

is the critical, but the use of V-type engines for larger power units has enabled to place the

engine transversely. Consequently, the placement of all the main components under the bonnet

(hood), and the removal of floor bulges and tunnel provide maximum space for the rear

passengers. Transverse mounting of the engine also simplifies the transmission. The use of

bevel-type final drive is eliminated; instead a simple reduction gear along with a differential

transmits the power through short drive shafts to the road wheels. Each drive shaft is fitted

with an inner and outer universal joint. The outer joint accommodates the steering action and

is specially designed to transmit the drive through a large angle. When the front wheels are

used for steering, the driving force acts in the same direction as the wheel is pointing. Also the

Fig. 1.24. Mid-engined car

Fig. 1.25. Rear-wheel drive.

vehicle is being ‘dragged’ behind the front driving wheels. These features improve vehicle

handling especially in slippery conditions.

Fig. 1.26. Front-wheel drive.

Mounting the main units in one-assembly some-times makes it difficult to gain access to

some parts, but this problem has largely been overcome now a days. One disadvantage is that

the driving wheels have fewer grips on the road when the vehicle is accelerating and negotiating

a gradient. This problem can be partly rectified by placing the engine well forward to increase

the load on the driving wheels, but the car is then liable to become ‘nose-heavy’ causing the

steering more arduous. In cases where the driver’s steering effort becomes excessive, the car is

often fitted with power-assisted steering.

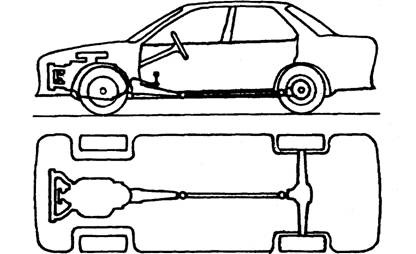

Fig. 1.27. Four-wheel drive.

Four-wheel Drive. This arrangement (Fig. 1.27) is safer because of distribution of the drive

to all four wheels. The sharing of the load between the four wheels during acceleration reduces

the risks of wheel spin specifically on slippery surfaces like snow and mud. In addition the

positive drive to each wheel during braking minimizes the possibility of wheel lock- up. On an

icy road or across off-highway a two-wheel-drive vehicle soon becomes non-drivable due to the

loss of grip of one of the driving wheels which causes the wheel to spin.