26.3.

Rear-wheel Drive Arrangements

The statement “every action has an equal and opposite reaction”, means that every component that produces or changes a torque also exerts an equal and opposite torque tending to turn the casing. To understand the torque reaction consider the Fig. 26.25A, which represents a tractor with its rear driving wheels locked in a ditch. In this situation torque reaction is likely to lift the front of the tractor rather than turn the rear wheels. When the above principle is applied to rear axles, some arrangement must be provided to prevent the axle casing turning in the opposite direction to the driving wheels.

A torque (t) applied to the wheel, which may be considered as a lever (Fig. 26.25B), produces a tractive effort (Te) at the road surface, and an equal and opposite forward force at the axle shaft. This driving thrust must be transferred from the axle casing to the frame in order to propel the vehicle. The maximum tractive effort is limited by the adhesive force (P) of the type on the road. This force depends on the coefficient of friction (u) and the load (W) on the wheel.

Fig. 26.25. Lever action of a wheel.

Types of Drive.

A drive system is an arrangement, which transmits the driving thrust from the road wheels to the vehicle body and also incorporates a means to resist the movement of the main components due to torque reaction.

In the early days only leaf springs were used for the rear suspension of a vehicle, and hence these springs were often utilized to provide the drive thrust and torque reaction functions of the drive system. Since 1950, three notable drive systems are in use on motor cars and these basic systems have undergone several modifications to meet modern requirements. The drive systems include,

• Hotchkiss open-type • Four-link (semi-Hotchkiss)

• Torque tube • de-Dion.

Although these systems are not used today in their original form, the objective of describing them is to make the reader familiar with the arrangement used to resist the various forces associated with the propulsion of a vehicle. However, this knowledge may help in the diagnosis of many of the faults associated with drive systems.

26.3.1.

Hotchkiss Open-type Drive

This type of drive is commonly used on passenger cars and heavy commercial vehicles. This arrangement (Fig. 26.26) uses two rear leaf springs, which are longitudinally mounted, and are connected to the frame by a ‘fixed’ pivot at the front, and swinging shackles at the rear. A universal joint is mounted at each end of the exposed or ‘open’ type propeller shaft, with provision for accommodating change in shaft length due to the deflection of the springs. This drive, therefore, incorporates an open propeller shaft with two universal joints and a slip joint.

Fig. 26.26. Hotchkiss open-type drive (light commercial vehicle).

To resist torque reaction the axle is clamped to the springs using ‘U’ bolts. Under heavy driving conditions the springs deflect up at the front and down at the rear and vice versa during braking. This movement helps to damp driving shocks and improves transmission flexibility. A universal joint is installed at rear to accommodate continuous up and down motion of the axle. Driving thrust is transferred from casing to the spring by the friction between the two surfaces, and then transmitted through the front section of the springs to the vehicle frame. If the ‘U’ bolts become loose, the spring centre bolt (axle location bolt) has to take the full driving thrust, so that early failure of the bolt takes place due to the high shearing force.

Fig. 26.27. Forces acting on Hotchkiss drive.

In the Hotchkiss drive, rear axle torque and the propelling and retarding forces are taken up by the rear springs. The rear springs, which are generally half-elliptic type, are shackled to spring seats on the axle housing at one end and are pinned to the chassis frame at their forward end. The shackles may be vertical or may be arranged at some angle (a) as shown in Fig. 26.27. Thus the springs act as both torque and thrust members in this case.

Fig. 26.28. Free body diagram of Hotchkiss drive.

26.3.2.

Four-link (Semi-Hotchkiss) Drive

When helical springs are used in conjunction with a live rear axle, these springs cannot take driving and braking thrust, torque reaction or give lateral support to the rear axle. Therefore additional arrangements must be incorporated to meet these requirements. It may appear that the helical spring provides a reduction in the unsprung weight, but in practice when the weight of the additional locating arms and rods fitted to support this arrangement is added, the unsprung weight difference becomes very small. However, this layout allows for an accurate positioning of the axle which is an advantage.

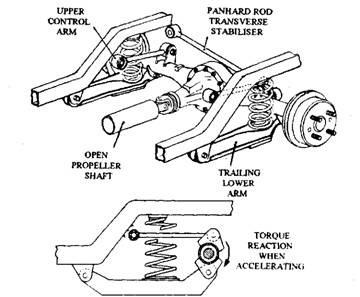

The rear axles is positioned by upper and lower trailing suspension arms in the four-link drive system layout as illustrated in Fig. 26.29. These arms transmit driving thrust and prevent rotation of the axle casing. A transverse stabilizer, called a Panhard rod, connects the rear axle to the vehicle body and thereby controls sideways movement of the axle. Rubber mountings are fitted at each connection point to reduce noise transmission and to eliminate the need for lubrication. Also these mountings provide slight flexibility to allow for drive movement and geometric variations during spring deflection.

Fig. 26.29. Helical spring and four-link suspension.

26.3.3.

Torque-tube Drive

This drive system is generally used in passenger cars and light commercial vehicles. Whereas the Hochkiss drive uses stiff springs to resist torque reaction and driving thrust, the torque tube drive permits the use of either ‘softer’ springs or another form of spring, like helical to perform their only intended duty so that a ‘softer’ ride is possible. Figure 26.30 illustrates a layout using laminated springs, which are connected to the frame by a swinging shackle at each end. A tubular member called torque-tube, encloses the propeller shaft and is bolted rigidly to the axle casing. The torque-tube is positioned at the front by a ball and socket joint, which is located at the rear of the gearbox or cross-member of the frame. Bracing rods are introduced between the axle casing and the torque tube to strengthen the arrangement. A small-diameter propeller shaft is installed inside the torque tube and splined to the final-drive pinion. A

universal joint is installed in the centre of the ball joint to allow for angular deflections of the drive.

Fig. 26.30. Torque tube drive.

In this design the torque reaction and driving thrust are taken up by the torque tube. Since the forward thrust from the ball is taken on the rear housing of the gearbox, arrangements must be incorporated to transfer this force through the gearbox mountings to the frame. When helical or torsion bar springs are used as alternatives to laminated springs, side movement of the axle must be controlled by providing some form of transverse stabilizer, such as a Panhard rod, between the frame and the axle. This system uses one universal joint and a slip joint. Since the torque tube is fitted rigidly to the rear-axle centre housing, this eliminates the use of a universal joint at the rear end of the propeller shaft.

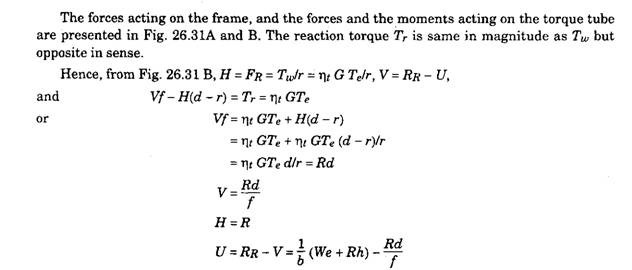

A torque tube has been presented diagrammatically in Fig. 26.31, indicating all the forces acting on this drive. All the notations of section 26.3.1 hold good for this case also.

Fig. 26,31. Forces acting on torque tube drive.

Fig. 26.32. Free body diagram of torque tube.

26.3.4.

de-Dion Drive

The de-Dion axle is often considered as the halfway stage between the normal axle and independent suspension. This layout provides many of the advantages of the independent suspension, but the system is not classed as independent, as the rear wheels are still linked by an axle tube.

In the basic arrangement illustrated in Fig. 26.33, laminated springs are mounted on the frame by a ‘fixed’ pivot at the front and a swinging shackle at the rear. To support the wheel on a stub axle shaft, each spring is equipped with a hub mounting, which is rigidly connected to a tubular axle beam. The final-drive unit, which is bolted to a cross-member of the frame, transfers the drive to road wheels through two universally jointed shafts. The main propeller shaft is fitted with a universal joint at each end to allow for flexing of the

Fig. 26.33. de-Dion drive.

frame. In this design, the torque reaction of the final-drive casing is absorbed by the frame, and the driving thrust is resisted by the springs.

The major advantage of this arrangement is the reduction in unsprung weight. This reduces wheel spin by permitting the light driving wheels to follow closely the contour of the road surface. Wheel spin is also caused by the tendency of the normal axle to rotate around the pinion due to a high propeller shaft torque. This lifting tendency of the wheel is eliminated in this drive system, and weight is equally distributed.