Front Axle and Steering System

Front axle carries the weight of the front part of the automobile as well as facilitates steering and absorbs shocks due to road surface variations. The front axles are generally dead axles, but are live axles in small cars of compact designs and also in case of four-wheel drive. The steering system converts the rotary motion of the driver’s steering wheel into the angular turning of the front wheels as well as to multiply the driver’s effort with leverage or mechanical advantage for turning the wheels. The steering system, in addition to directing the vehicle in a particular direction must be arranged geometrically in such a way so that the wheels undergo true rolling motion without slipping or scuffing. Moreover, the steering must be light and stable with a certain degree of self-adjusting ability. Steering systems may also be power assisted. The chapter discusses the front axle construction and its alignment, and steering geometry and steering systems.

27.1.

Front Axle

The front axle (Fig. 27.1) is designed to transmit the weight of the automobile from the springs to the front wheels, turning right or left as required. To prevent interference due to front engine location, and for providing greater stability and safety at high speeds by lowering the centre of gravity of the road vehicles, the entire centre portion of the axle is dropped. As shown in Fig. 27.1, front axle includes the axle-beam, stub-axles with brake assemblies, u ack-rod and stub-axle arm.

Front axles can be live axles and dead axles. A live front axle contains the differential mechanism through which the engine power flows towards the front wheels. For steering the front wheels, constant velocity joints are contained in the axle half shafts. Without affecting the power flow through the half shafts, these joints help in turning the stub axles around the king-pin.

The front axles are generally dead axles, which does not transmit power. The front wheel hubs rotate on antifriction bearings of tapered-roller type on the steering spindles, which are an integral part of steering knuckles. To permit the wheels to be turned by the steering gear, the steering spindle and steering knuckle assemblies are hinged on the end of axle. The pin that forms the pivot of this hinge is known as king pin or steering knuckle pin. Generally dead front axles are three types. In the Elliot type front axles the yoke for king spindle is located on the ends of I-beam. The axle ends are forked to hold the steering knuckle extension between them. The reverse Elliot front axles have hinged spindle yoke on spindle itself instead of on the

axle. The forked portion is integral with the steering knuckle. This type is commonly used as this facilitates the mounting of brake backing plate on the forged legs of the steering knuckle. In the Lemoine type front axle, instead of a yoke type hinge, an L-shaped spindle is used which is attached to the end of the axle by means of a pivot. It is normally used in tractors.

Fig. 27.1. Front axle.

The axle beam in use is of I or H-section and is manufactured from alloy forged steel for rigidity and strength. As compared to dead front axles, a totally different type of swivelling mechanism is used on the live front axle. To connect the wheel hub axles with driving axle shafts, constant velocity joints are used for the vehicles fitted with the front live axles. Tracta, Rzeppa (or Sheppa) on Bendix constant velocity or universal joints are normally used.

Front axles are subjected to both bending and shear stresses. In the static condition, the axle may be considered as a beam supported vertically upward at the ends i.e. at the centre of the wheels and loaded vertically downward at the centres of the spring pads. The vertical bending moment thus caused is zero at the point of support and rises linearly to a maximum at the point of loading and then remains constant.

Thus the maximum bending moment = Wl, Nm

where, W = The load on one wheel, N

I = The distance between the centre of wheel and the spring pad, m

Under dynamic conditions, the vertical bending moment is increased due to road roughness.

But its estimate is difficult and hence is generally accounted for through a factor of safety. The front axle also experiences a horizontal bending moment because of resistance to motion and this is of a nature similar to the vertical one but of very small magnitude and hence can be neglected except in those situations when it is comparatively large.

The resistance to motion also causes a torque in the case of drop type front axle as shown in Fig. 27.2. Thus the portions projected after the spring pads are subjected to combined bending and torsion.

Fig. 27.2. Loads on front axle.

The shear stress in the axle is due to braking torque and its magnitude (as shown in Fig. 27.2)

27.1.1.

Types of Front Hub Assembly

The stub axle construction depends on whether it is a driving or non-driving hub.

Non-driving Hub.

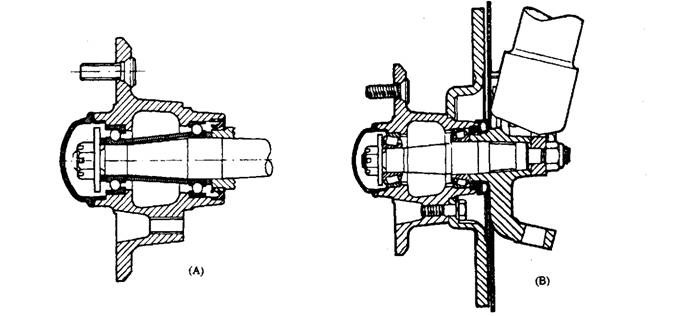

Figure 27.4A illustrates a typical bearing arrangement for a non-driving hub. This consists of a stub-axle, an externally cylindrical sleeve hub, a pair of taper-roller bearings, a grease-seal, a castellated adjustment nut and split-pin, a washer, and a dust-cap (Fig. 27.7).

A centrally flanged cylindrical sleeve hub is fitted over small outer and large inner taper-roller bearings, which are supported on the stub axle. The hub is made of malleable iron or steel cast. The bearings are designed to absorb both radial and axial loads when assembled. The slackness between the taper rollers and the inner and outer races are taken up by spinning the hub assembly while at the same time tightening the adjustment nut until all the free lay has been taken up. The bearings are then preloaded by tightening the nut with a torque wrench to some predetermined torque setting. The nut is then slackened slightly until one of the slots in the nut aligns with the hole in the stub-axle. The split pin is then inserted through and bent over to secure the nut in position.

fig.27.4. Front bearing-hub assembly. A. Taper roller type. B. Ball bearing type.

For more accurate setting, some manufactures recommend to tighten the adjusting nut to a specified torque before releasing the nut a given amount. This operation, however, should not be confused with preloading. As hub bearing withstands heat from the brakes, a running clearance is provided, which is quite different to that obtained after a bearing has been preloaded. The flanged hub supports the road wheels and a brake drum or a brake disc. A dust cap with a central vent hole is used to enclose the end of the hub. This area of the hub sliouid not be filled with grease.

An alternative bearing arrangement is presented in Fig. 27.4B, which uses two angular contact type ball races held apart by a rigid spacer. The nut on this non-adjustable hub are tightened fully to the correct torque value.

Driving Hub.

Figure 27.5 illustrates a typical hub arrangement used for a front-wheel drive car. The stub axle housing uses two bearings, which support both the wheel hub and driving shaft. The type of bearing used is decided based on the load carrying capacity of the road wheel.

Fig. 27.5. Front hub with front-wheel drive.

27.1.2.

Bearing Loads on the Front Axle

Figure 27.6 illustrates the forces and the reactions on steering knuckle when the vehicle is at rest. The thrust load and the knuckle-pin-bearing load can be expressed in terms of the reaction of wheel on wheel spindle.

Let, Rw = The reaction of the wheel on the spindle acting vertically through the centre of contact of tyre on ground. Rt = The load on the thrust bearing

Ru = The load on the upper knucklepin bearing Rl = The load on lower knucklepin

‘B’ and ‘C represent the centres of lower and upper knuckle-pin bearings respectively. ‘A’ is a point on the spindle axis in the centre plane of the wheel.

![]()

Fig. 27.6. Forces and reaction on steering knuckle.

The other loads acting on knuckle-pin bearing are those due to the rolling resistance and road shocks. These loads are proportional to the static load and hence can be accounted for.

27.1.3.

Bearing Lubrication

The whole hub assembly is partially packed with grease. A radial-lip grease-seal is pressed inside the hub next to the larger bearing. The lip of the seal faces this bearing and fits over the cylindrically machined surface on the stub-axle.

Over packing bearing hubs with grease causes churning and develops very high running temperatures. Due to high temperatures and excessive mechanical working the grease breaks down and becomes soft. The centrifugal force acting on the grease in the hub pushes soft grease outwards, so that it flows towards the lip seal and seeps past the seal lips. Bearing greases are based on mineral oil and to thicken the oil soaps of calcium, sodium, or lithium compounds are added. The consistency of a grease depends on the viscosity of the base oil as well as on the structure and properties of the metallic soap added. The three most important properties of a grease includes

(i) the melting temperature, at which the grease loses its semi-solid state,

(ii) its resistance to contamination and dilution by water, and

(Hi) its ability to withstand mechanical working before the grease breaks. The relative operating properties of commonly used bearing greases are provided in Table 27.1.

Table 27.1. Operating properties of commonly used greases.

| Upper temperature limits | ||||

| Types of grease soap | Short duration K | Continuous K | Water resistance | Mechanical stability |

| Calcium | 353 | 323 | Good | Fair |

| Sodium | 393 | 353 | Poor | Good |

| Lithium | 423 | 393 | Good | Good |

For checking the bearing and seal, the split-pin and the castellated nut on the end of the stub-axle are removed and the hub assembly is withdrawn. All parts are thoroughly washed in paraffin, and the bearing rollers and tracks are examined for wear and damage. Before replacing the hub, the inside of the hub and the bearings are applied with grease (Fig. 27.7).

Fig. 27.7. Axle-beam and stub-axle assembly.