It is important to determine the physical and chemical characterizations of crude oil through a crude oil assay, since they are used in different areas in the petroleum refining industry. The most common applications of petroleum assays are:

• To provide extensive detailed experimental data for refiners to establish the compatibility of a crude oil for a particular petroleum refinery

• To anticipate if the crude oil will fulfill the required product yield, quality, and production

• To determine if during refining the crude oil will meet environmental and other standards

• To help refiners to make decisions about changes in plant operation, development of product schedules, and examination of future processing ventures

• To supply engineering companies with detailed crude oil analyses for their process design of petroleum refining plants

• To facilitate companies’ crude oil pricing and to negotiate possible penalties due to impurities and other nondesired properties

A crude oil assay is a compilation of laboratory (physical and chemical properties) and pilot-plant (distillation and product fractionation) data that characterize a specific crude oil. Assay analyses of whole crude oils are carried out by combining atmospheric and vacuum distillation units, which when combined will provide a true boiling-point (TBP) distillation. These batch distillation methods, although taking between 3 and 5 days, allow the collection of a sufficient amount of distillation fractions for use in further testing. The values of the distillation ranges of the distilled fractions are usually defined on the basis of their refinery product classifications. The most common distillation ranges used in international assays of crude oils are reported in Table 1.5.

TABLE 1.5. Typical Distillation Range of Fractions in Petroleum Assays

|

TBP Distillation |

|

|

Range (°C) |

Distillate |

|

IBP-71 |

Light straight-run naphtha |

|

71-177 |

Medium straight-run naphtha |

|

177-204 |

Heavy straight-run naphtha |

|

204-274 |

Jet fuel |

|

274-316 |

Kerosene |

|

316-343 |

Straight-run gasoil |

|

343-454 |

Light vacuum gasoil |

|

454-538 |

Heavy vacuum gasoil |

|

R 538°C+ |

Vacuum residue |

There are various types of assays, which vary considerably in the amount of experimental information determined. Some include yields and properties of the streams used as feed for catalytic reforming (naphtha) and catalytic cracking (gas oils). Others give additional details for the potential production of lubricant oil and/or asphalt. At a minimum, the assay should contain a distillation curve (typically, TBP distillation) for the crude oil and a specific gravity curve.

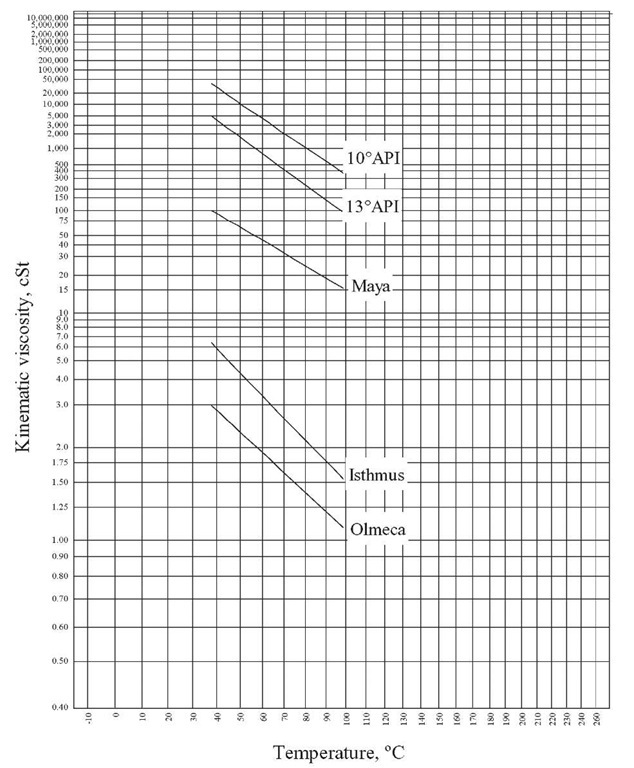

The most complete assay includes experimental characterization of the entire crude oil fraction and various boiling-range fractions. Curves of TBP, specific gravity, and sulfur content are normal data contained in a well-produced assay. As an example, assays of various Mexican crude oils are presented in Table 1.6. The API gravity of these crude oils ranges from 10 to 33°API. API gravity is a measure of the relative density of a petroleum liquid and the density of water (i.e., how heavy or light a petroleum liquid is compared to water). Although, mathematically, API gravity has no units, it is always referred to as being in "degrees." The correlation between specific gravity (sg) and degrees API is as follows (the specific gravity and the API gravity are both at 60°F):

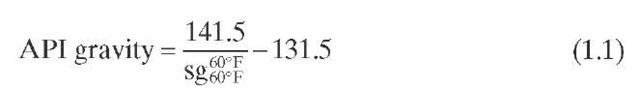

Viscosity must be provided at a minimum of three temperatures so that one can calculate the sample viscosity at other temperatures. The most common temperatures used to determine viscosity are 15.5, 21.1, and 25°C. If viscosities of the sample cannot be measured at those temperatures, the sample needs to be heated and higher temperatures are used, such as in the case of the 10 and 13°API crude oils reported in Table 1.6. Once viscosities at three temperatures are available, a plot of a double logarithm (log10) of viscosity against the temperature can be constructed, and viscosities at other temperatures can be obtained easily, as shown in Figure 1.1.

The characterization factor (KUOP or KWatson) of the Mexican crude oils reported in Table 1.6 ranges from 11.5 to 12.0. The K factor is not determined experimentally; rather, it is calculated using the following equation (for petroleum fractions):

where MeABP (in degrees Rankine) is the mean average boiling point of the sample calculated with distillation curve data.

In general, if K > 12.5, the sample is predominantly paraffinic in nature, while K < 10.0 is indicative of highly aromatic material. The characterization factor thus provides a means for roughly identifying the general origin and nature of petroleum solely on the basis of two observable physical parameters, sg and MeABP. More detailed relationships of the K factor to the nature of the sample are given in Table 1.7 . The characterization factor has also been related to other properties (e.g., viscosity, aniline point, molecular weight, critical temperature, percentage of hydrocarbons), so it can be estimated using a number of petroleum properties.

TABLE 1.6. Assay of Various Mexican Crude Oils

|

ASTM Method |

|

|

Crude Oil |

|

|

|

|

10 ° API |

13 ° API |

Maya |

Isthmus |

Olmeca |

||

|

Specific gravity, 60°F/60°F |

D-1298 |

1.0008 |

0.9801 |

0.9260 |

0.8584 |

0.8315 |

|

API gravity |

D – 287 |

9.89 |

12.87 |

21.31 |

33.34 |

38.67 |

|

Kinematic viscosity (cSt) |

D-445 |

|||||

|

At 15.5°C |

— |

— |

299.2 |

16.0 |

5.4 |

|

|

At 21.1°C |

— |

— |

221.6 |

12.5 |

4.6 |

|

|

At 25.0°C |

— |

19,646 |

181.4 |

10.3 |

4.1 |

|

|

At 37.8°C |

— |

5,102 |

— |

— |

||

|

At 54.4°C |

7,081 |

1,235 |

— |

— |

||

|

At 60.0°C |

4,426 |

— |

— |

— |

||

|

At 70.0°C |

2,068 |

— |

— |

— |

||

|

Characterization factor, ,KUOP |

UOP-375 |

11.50 |

11.60 |

11.71 |

11.95 |

12.00 |

|

Pour point ( ° C) |

D – 97 |

+ 12 |

0 |

— |

-33 |

-39 |

|

Ramsbottom carbon (wt%) |

D-524 |

20.67 |

16.06 |

10.87 |

4.02 |

2.10 |

|

Conradson carbon (wt%) |

D – 189 |

20.42 |

17.94 |

11.42 |

4.85 |

2.76 |

|

Water and sediments (vol%) |

D – 4007 |

1.40 |

0.10 |

0.20 |

<0.05 |

< 0.05 |

|

Total sulfur (wt%) |

D – 4294 |

5.72 |

5.35 |

3.57 |

1.46 |

0.99 |

|

Salt content (PTB) |

D – 3230 |

744.0 |

17.7 |

15.0 |

4.1 |

3.9 |

|

Hydrogen sulfide (mg/kg) |

uOP – 163 |

— |

— |

— |

44 |

59 |

|

Mercaptans (mg/kg) |

uOP – 163 |

— |

— |

— |

65 |

75 |

|

Total acid number (mg KOH/g) |

D-664 |

0.48 |

0.34 |

0.30 |

0.61 |

0.46 |

|

Total nitrogen (wppm) |

D4629 |

5650 |

4761 |

3200 |

1467 |

737 |

|

Basic nitrogen (wppm) |

uOP – 313 |

1275 |

1779 |

748 |

389 |

150 |

|

nC7 insolubles (wt%) |

D-3279 |

25.06 |

18.03 |

11.32 |

1.65 |

0.68 |

|

Toluene insolubles (wt%) |

D – 4055 |

0.41 |

0.20 |

0.11 |

0.09 |

0.11 |

|

Metals (wppm) |

Atomic absorption |

|||||

|

Nickel |

94.2 |

83.4 |

53.4 |

8.9 |

1.6 |

|

|

Vanadium |

494.0 |

445.0 |

298.1 |

37.1 |

8.0 |

|

|

Total |

588.2 |

528.4 |

351.5 |

46.0 |

9.6 |

|

|

Chloride content (wppm) |

D – 808 |

86 |

10 |

4 |

10 |

9 |

Figure 1.1. Kinematic viscosities of several Mexican crude oils.

TABLE 1.7. Relationship of Type of Hydrocarbon to the Characterization Factor

|

K Factor |

Type of Hydrocarbon |

|

12.15 – 12.90 |

Paraffinic |

|

11.50-12.10 |

Naphthenic-p araffinic |

|

11.00-11.45 |

Naphthenic |

|

10.50-10.90 |

Aromatic-naphthenic |

|

10.00-10.45 |

Aromatic |

Figure 1.2. True boiling-point curve of various Mexican crude oils.

Asphaltenes, which are generally reported as n- heptane insolubles, are, strictly speaking, defined as the weight percentage of n- heptane insolubles (HIs) minus the weight percentage of toluene insolubles (TIs) in the sample (wt% of asphaltenes = wt% of HI – wt% of TI). For the crude oils given in Table 1.6 , their asphaltene contents are 24.65, 17.83, 11.21, 1.56, and 0.57 wt% for the 10) API, 13°API, Maya, Isthmus, and Olmeca crude oils, respectively.

Figure 1.3. API gravity of distillates versus average volume percentage.

Figure 1.4. Sulfur content of distillates versus average volume percentage.

TBP distillations for Mexican crude oils are presented in Figure 1.2 . It is clear that light crude oils that have high API gravity values present also the highest amounts of distillates [e.g., Olmeca crude oil (38.67°API) has 88.1 vol% distillates, whereas the 10° API has only 46vol% distillates]. Figures 1.3 and 1.4 illustrate plots of API gravity and the sulfur content of distillates against the average volume percentage of distillates of the various crude oils. Distillates of heavier crude oils have lower API gravity and a higher sulfur content than those obtained from light crude oils.