In this section, we will briefly review the different types of variable-speed drives used in industry. For the most part, electronic AC and DC drives find their dominance in manufacturing and commercial HVAC applications of today. This brief look at drive technologies will assist you, should you encounter any of these types in the future. In addition, we will also review the benefits and limitations of each type. The types of drives we will consider are mechanical, hydraulic, and electrical/electronic (eddy-current coupling, rotating DC, DC converters, and variable-frequency AC).

Mechanical

Mechanical variable-speed drives were probably the first type of drive to make their way into the industrial environment. Figure 1-7 shows a basic mechanical variable-speed drive.

Figure 1-7. Mechanical variable-speed drive

As seen in Figure 1-7, the mechanical drive operates on the principle of variable-pitch pulleys. The pulleys are usually spring-loaded and can expand or contract in diameter by means of a hand crank (shown on the left side of the constant speed AC motor). The mechanical drive still gets its power source from an AC power supply—usually three-phase AC. Three-phase AC is then fed to the fixed-speed AC motor. The ability to vary the diameter of one or both pulleys gives this drive unit the ability to change its output speed (seen in the lower portion of Figure 1-7). The principle of variable speed is exactly the same as the gears of a 15-speed bicycle. Shifting gears causes the chain to slip into a wider- or narrower-diameter sprocket. When that happens, a faster or slower speed is achieved with basically the same input power.

Years ago, the benefits of this type of drive were low cost and the ability to easily service the unit. Many technicians liked to work on mechanical problems. The malfunction was rather obvious. However, the benefits of yesterday have turned into the limitations of today. Mechanical devices have a tendency to break down—requiring maintenance and downtime. The efficiency of the unit can range from 90% down to 50% or lower. This is due to the eventual slipping of the belt on the pulleys (sometimes called sheaves). Sometimes the speed range can be a limitation because of fixed diameter settings, a characteristic of the mechanics of the device. Size can also be a limitation. Typically floor-mounted, this device sometimes stood 3-5 feet tall for general applications. Size and weight could prohibit the use of this device in areas that would be required for mounting a drive.

Hydraulic Drives

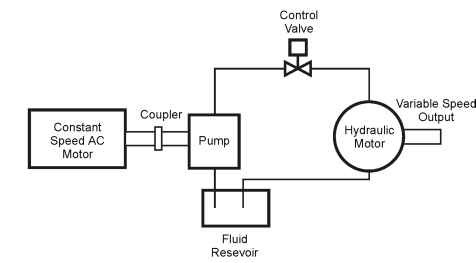

Hydraulic drives have been, and continue to be, the workhorse of many metals processing and manufacturing applications. The hydraulic motor’s small size makes it ideal for situations where high power is needed in very tight locations. In fact, the hydraulic motor’s size is 1/4-1/3 the size of an equivalent power electric motor. Figure 1-8 indicates a hydraulic drive.

Figure 1-8. Hydraulic drive

In Figure 1-8, a constant-speed AC motor operates a hydraulic pump. The pump builds up the necessary operating pressure in the system to allow the hydraulic motor to develop its rated power. The speed control comes from the control valve. This valve operates like a water faucet—the more the valve is open, the more fluid passes through the system, and the faster the speed of the hydraulic motor. Note that this system uses a coupler to connect the AC motor to the pump.

The benefits of this type of drive system is the ability of the hydraulic motor to develop high torque (twisting motion of the shaft). In addition, it has a fairly simple control scheme (a valve), which operates at a wide

speed range and has an extremely small size compare to most AC motors of the same power.

However, this type of system has several major limitations. The most limiting factor of this system is the need for hydraulic hoses, fittings, and fluid. This system is inherently prone to leaks, leading to high maintenance costs. In addition, there is virtually no way to connect this system to an electronic controller. Automatic valve-type controls have been developed, but their use is limited in today’s high-speed manufacturing environment.

Eddy-Current Drives

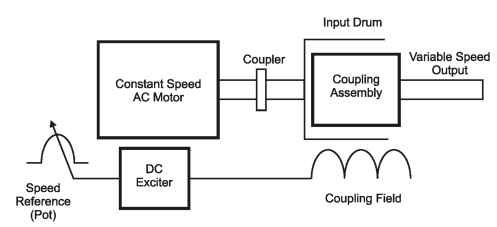

Eddy-current drives have their roots in the heavy machinery part of industry. Grinding wheels are prime candidates for eddy-current drives. This system uses an AC-to-DC power-conversion process, which allows variable shaft speeds, depending on the amount of power converted. Figure 1-9 indicates a simple eddy-current drive system.

Figure 1-9. Eddy-current drive system

As seen in Figure 1-9, an AC motor operates at a fixed speed. This causes the input drum to operate at the same speed. The function of the DC exciter is to convert AC power to DC power. This power is then fed to the coupling field. The coupling field generates a magnetic field based on how much DC power is being produced by the DC exciter. The more power produced, the more magnetic field is produced and the stronger the attraction of the coupling assembly to the input drum. How much power produced by the DC exciter is determined by the speed reference potentiometer (speed pot).

The benefits of an eddy-current system include initial cost and the simple control method (usually 1 speed pot). In addition, this type of system can produce regulated torque because of its ability to fairly accurately control the DC exciter.

However, several limitations dictate where and how this type of system is applied. Heat generation and power consumption are the major issues. For

the coupling assembly to magnetically couple to the input drum, a large amount of power must be produced. When power is produced, heat is the by-product, and energy savings are not realized. Compared with other types of variable-speed drives, this type can be several times larger, thereby limiting the locations where it can be mounted. Size is also an issue when maintenance is required on the rotating machinery. Typically on-site repairs are required, which is more costly than shipping the unit back to the repair location.

Rotating DC Drives

This system dates back to the mid 1940s. The system also gained the name M-G set, which stands for motor-generator set. As seen in Figure 1-10, that description is quite accurate.

Figure 1-10. Rotating DC variable-speed drive

As seen in Figure 1-10, the variable-speed system is more complicated than an eddy-current system. The constant-speed AC motor causes the DC generator to produce DC power. The amount of power produced by the generator is dependent on the magnetic strength of the field exciter of the generator. The field exciter strength is determined by the position of the speed pot. As will be shown later, the DC motor requires two circuits in order to operate properly. In this case, the DC generator feeds power to the main circuit of the DC motor (called the armature). The DC motor also needs another circuit called the field. The field magnetism interacts with the magnetism in the main circuit (armature) to produce rotation of the motor shaft. The strength of the field magnetism depends on how much power is produced by the motor field exciter. The field exciter strength is determined by the position of the DC-motor speed pot.

This system has several benefits. Years ago in the rotating machinery industry, this equipment was very traditional equipment. This system also had the ability to control speed accurately and had a wide speed range. It typically used motors and generator equipment that had a very large overload capacity, compared with modern-day motors.

Today, a system of this type, however, would carry several limitations. Because of the need for three rotating units (AC motor, DC generator, and DC motor), this system is prone to maintenance issues. DC equipment uses devices called brushes, which transfer power from one circuit to the other. These devices need periodic replacement, meaning the machine needs to be shut down. This system is also larger than many of the other variable-speed units. In today’s industrial environment, replacement parts are harder to find. The early units used a power conversion device called a vacuum tube (high-temperature electrical conduction), which is very difficult to acquire as a spare part. As to be expected, three rotating units increases the maintenance required on mechanical parts.

Electronic Drives (DC)

DC drives have been the backbone of industry, dating back to the 1940s. At that time, vacuum tubes provided the power conversion technology. Vacuum tubes led to solid-state devices in the 1960s. The power conversion device, called the silicon controlled rectifier (SCR), or thyristor, is now used in modern electronic DC drives. Figure 1-11 indicates the main components of a simple DC drive system.

Figure 1-11. Electronic DC drive

As seen in Figure 1-11, the DC drive is basically a simple power converter. It contains two separate power circuits, much like that of the rotating DC unit. Typically, three-phase AC power is fed to the drive unit. (Note: Some small horsepower DC drives will accept one-phase power.) The drive unit uses SCRs to convert AC power to DC power. The speed pot determines how much the SCRs will conduct power. The more the SCRs conduct power, the more magnetic field is generated in the main DC motor circuit, the armature.

In a DC-drive system, there is always a separate magnetic circuit, called a field. The strength of the magnetic field is determined by the separate motor field exciter, or a permanent magnet. The motor field is usually kept at full strength, although in some cases, the field will be weakened to produce a higher-than-normal speed. The interaction between the motor armature and field produces the turning of the motor shaft. We will go into further detail on DC-drive technology later in this topic.

There are some definite benefits to a variable-speed drive system of this type. This mature technology has been available for more than 60 years. Because electronic technology is used, a wide variety of control options are available.

Monitors such as speed and load meters and operating data circuits can be connected to illustrate drive operation. A remote operator station, including an isolated speed reference and start/stop circuits, can also be connected to the drive. This type of remote control allows commands from distant locations in the building. The DC drive offers acceptable efficiency, when compared with other variable-speed technologies. In addition, DC drives offer a small size power unit and comparable low cost in relation to other electronic drive technologies. However, when comparing electronic DC-drive technology with AC technology, several limitations should be considered.

Probably the largest issue with DC-drive systems is the need for maintenance on the DC motor. As indicated in the rotating DC-drive section, DC motors need routine maintenance on brushes and the commutator bars. Another issue that is critical to many manufacturing applications is the need for back-up capability. If the DC drive malfunctions, there is no way to provide motor operation, except through connection of another DC drive. In this day of efficient power usage, the DC drive’s varying power factor must be considered when planning any installation. Total operational costs (maintenance, installation, and monthly operating costs) may be a limitation when comparing the DC system with the AC-drive system.

Electronic Drives (AC)

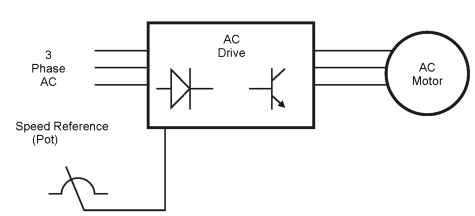

Basically, three types of AC drive technologies are currently available. Though each type differs in the way power is converted, the end result is the use of a variable-speed AC induction motor. All AC drives take AC input, convert it to DC, and change DC to a variable AC output, using a device called an inverter (i.e., inverts DC back to AC voltage). For purposes of this section, we will confine our discussion to a generic AC drive.

Figure 1-12 indicates a generic AC drive and its basic components.

The basic objective involved in an AC drive is to change a fixed incoming line voltage (V) and frequency (Hz) to a variable voltage and frequency output. The output frequency will determine how fast the motor rotates. The combination of volts and Hertz will dictate the amount of torque the motor will generate.

Figure 1-12. Variable-speed AC drive

When we look closer at the principles involved, we find that the AC drive essentially changes AC power to DC power. The DC power is then filtered and changed back to AC power but in a variable voltage and frequency format. The front end section consists of diodes. Diodes change AC power to DC power. A filter circuit then cleans up the DC waveform and sends it to the output section. The output section then inverts the DC power back to AC. This is accomplished through a series of transistors. These are special transistors that only turn on or turn off. The sequence and length in which these transistors turn on will determine the drive output and ultimately the speed of the motor.

With this type of variable-speed system, there are more benefits than limitations. When compared with DC drives, small-sized AC drives are equal to or lower in cost (5 HP or less). The efficiency of power conversion is comparable to that of DC drives. Also comparable is the ability to be controlled remotely and to have various monitor devices connected. Because of modern transistor technology, the size of the AC drive is equal to or even smaller than that of an equal horsepower DC drive (125-150 HP or less). One major advantage of AC drives is the ability to operate an AC motor in bypass mode. This means that while the drive is not functioning, the motor can still be operating, essentially across line power. The motor will be operating at full speed because of the line power input. But the benefit would be that the system continues to operate with little or no downtime.

There may be a few limitations when considering AC drive technology. With low horsepower units (above the 25- to 30-HP range), AC drives may carry a higher purchase price. However, the installation costs may be less because of less wiring (there is no separate field exciter). Some applications, such as printing and extrusion, lend themselves to DC technology. Comparable AC drives may need to be sized 1 or 2 HP frame sizes higher to accommodate the possible overload requirements. topic 4, section “Torque Control AC Drives” is devoted to flux vector and torque-controlled AC drives. More detail is presented on the issue of overload, torque

control, and AC/DC drive comparisons. Today’s AC-drive technology can provide impressive response, filling the application needs that traditionally used DC drives.