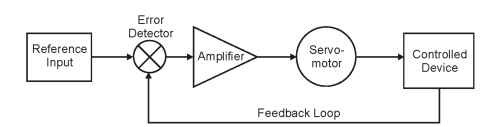

The servomotors used in industry today are used in a closed-loop servo system. To understand how the servomotor is used in the system, it is first necessary to review the entire system. Figure 3-44 indicates a block diagram of a typical servo system.

Figure 3-44. Typical servo system block diagram

A reference input (typically called a velocity input) is sent to the servo amplifier, which controls the speed of the servomotor. Directly mounted to the machine (or to the servomotor) is a feedback device (either an encoder or resolver). This device changes mechanical motion into electrical signals and is used as a feedback loop. This feedback loop is then sent to the error detector, which compares the actual operation with that of the reference

input. If there is an error, that error is fed directly to the amplifier, which makes the necessary corrections.

In many servo systems, both velocity and position are monitored. (Note: In servo systems, the word “velocity” is often used to describe speed control. Velocity indicates a rate of change of position, with respect to time. It also indicates a rate of motion in a particular direction, with respect to time.) The velocity loop control may take its command from the velocity loop feedback device—a resolver or tachometer mounted directly to the motor. The position loop control may take its command from the position feedback device—an encoder. Depending on the system, both devices may be mounted to the actual machine or controlled device.

The stability of the entire system is dependent upon the tuning of the components in the system and how well those components are matched. Tuning the system involves working with a PID (proportional integral derivative) control. This type of closed loop control is standard on all high-accuracy systems. The main factors in this closed loop system are the gain, integration time, and derivative time of the loop.

The amplifier gain must be set satisfactorily. The gain sets how responsive the amplifier will be during changes in error signal. A high gain will cause the motor to overshoot the intended speed target. Too low of a gain may mean that the target is reached late in the cycle, or possibly not at all.

The integration time allows the amplifier to respond to changes in the error signal, mostly at zero speed. The zero speed error signal is multiplied by the gain setting, and results in increased motor responsiveness (stiffness) and accuracy.

The derivative function is the most difficult to accurately adjust. This controls the dampening or oscillations of the system. This function basically dictates the amount of correction given per unit of error. The error signal can be corrected immediately (in milliseconds), or throughout a longer period of time (seconds).

If there is a difficult part to the tuning task, it would be during the derivative setup. The gain and integration time is interactive. One setting affects the other. Proper setup of the derivative function involves multiplying the position error by the position error rate (how much correction should take place per unit of time). If the system components are not matched, oscillations, overshoot, or undershoot of velocity can result, which means unstable operation.

Servomotors are special electromechanical devices that operate in precise degrees of rotation. This type of motor quickly responds to positive or negative signals from a servo amplifier. Fast and accurate speed, torque, and direction control are the mark of a servomotor’s characteristics. Very high starting torque must be obtained from the servomotor.

The standard AC

induction motor’s torque is measured in pound-feet. By contrast, the servomotor’s torque is measured in inch-pounds.

In today’s servo systems, three basic types of servomotors are used: AC, DC, and AC brushless. As one might expect, the AC design is based on AC induction motor characteristics. The DC design is based on the design of a DC motor. The brushless DC design is based on that of a synchronous motor. The basic principles of the DC and brushless DC servomotor have already been reviewed. We will therefore review the general characteristics of the AC servomotor. Linear devices will also be reviewed, since most of the position systems operate on linear technology.

AC Servomotors

This type of motor is basically a two-phase induction motor, capable of reverse operation. To achieve the dynamic requirements of a servo system, the servomotor must have a small diameter, low inertia, and high-resistance rotors. The low inertia allows for fast starts, stops, and reverse of direction. The high-resistance rotor provides for almost linear speed/ torque characteristics and accurate control.

An AC servomotor is designed with two phases set at right angles to each other. A fixed or reference winding is excited by a fixed voltage source. The control winding is excited by a variable voltage source, usually the servo amplifier. Both sets of windings are usually designed with the same voltage per turns ratio (meaning that with equal voltage applied to each winding, the same magnetic flux will be produced). This allows for maximum control of speed, with very little speed drift. In many cases, the design of the AC servomotor offers only reasonable efficiency, at the sacrifice of high starting torque and smooth speed response. Figure 3-45 indicates a typical AC servomotor design.

Linear Stepper Motor Systems

Linear stepper motor systems are based on the principles of the stepper motors previously presented. The stepper drive system is basically a servo system, but often without the velocity feedback loop. Without the feedback loop, some sacrifice in accuracy is made. However, the cost of a stepper motor system is less than that of servomotor system.

Stepper motors, as you recall, are two-phase stator-type motors. The current is carried in the stator, which allows for maximum heat dissipation. Current that is switched on and off creates an electromagnetic field that produces rotation. The position of the motor shaft is determined by which phase is at maximum strength. The pole pair that is at maximum strength will interact with the permanent magnet rotor, and rotation will occur.

The linear stepper system could be of several different designs, but several common types for stepper and servo systems are the rack and pinion system and the leadscrew system. Figure 3-46 indicates these two types of systems.

Figure 3-45. AC servomotor design

Figure 3-46. Linear stepper motor systems

In the rack and pinion design, the linear table is moved by the rotating motion of the stepper motor. The stepper motor shaft is fitted with a cylindrical gear that mates with linear table sprockets. When the stepper motor engages, the linear table moves in the forward or reverse direction, depending on the signal from the amplifier.

In the leadscrew design, the moveable table contains an integral nut that is threaded to the specifications of the long machine threaded screw. The stepper motor shaft is directly connected to the leadscrew by means of a coupling. When the motor engages, the leadscrew rotates in the direction dictated by the amplifier, thereby setting the table into motion.

A limiting factor to this system is the backlash that can occur, causing some sloppiness of motion. Backlash is the measured play or looseness between the gear and linear table sprocket (rack and pinion) or between leadscrew and moveable table (leadscrew). Since motion is transferred from the motor shaft to another device, this type of looseness is inevitable. Some backlash can be reduced by preloading the nut or linear device. This means that the linear device may be spring-loaded, keeping it in tight contact with the leadscrew nut, so there is no play in the system.

Linear Motors

Linear motor systems operate basically the same as rotating motors. The difference, of course, is that linear motion is produced, rather than clockwise or counterclockwise motion.

There are two main components of the linear stepper motor—the platen and the slider (sometimes referred to as the forcer). The platen could be considered the stator of the motor. The slider could be considered a linear rotor. Figure 3-47 indicates a linear stepper motor.

Figure 3-47. Linear stepper motor design

The electromagnetic “teeth” extend over the entire length of the platen. The slider also contains “teeth” and has both permanent magnets and coils that are electrically charged. It should be noted that the platen and slider have tooth structures that almost match. The slight offset is what causes the slider to be attracted to the next available magnetic field in the platen. The slider, in many cases, will contain air bearings that assist in developing a slight air gap. This air gap is where the magnetic flux is developed, and would be considered common to any standard AC induction motor.

When the slider coils are energized, the linear stepper motor moves in 1/4 tooth steps. Extremely fine resolution can be obtained from this type of

motor, in some cases up to 25,000 steps per inch. This type of motor is well suited for applications where fast acceleration and high-speed movements are required, but where low mass or weight is needed.

Speeds of up to 100 ips (inches per second) are possible, with movements in increments down to 0.00005 inches. The linear stepper motor system has its advantages in precision open-loop control, mechanical simplicity, reliability, applications where space is limited, and the ability for multiple motion (more than one slider can be applied onto one platen). In addition, this type of system is an alternative in applications where leadscrews (with backlash issues), belts, pulleys, and gears are not practical.