2.62.

Although slip gauges can be used for many purposes without the aid of any auxiliary

equipment, but their field of application is considerably extended by a few simple accessories, viz.,

holders, jaws, scribers and centre points etc. The use of holders becomes very important when it is

desired to use the slip gauge combination of considerable overall length, in order to ensure more

Fig. 2.174. Measuringjaws.

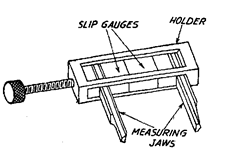

Fig. 2.175. Slip Gauge Accessories.

rigid assembly. The slip gauges after being selected are inserted in the holder (Refer Fig. 2.174)

which comprises of two slotted side plates secured to end block whereby they may be lightly clamped

in position. The gripping pressure is usually applied by means of a knurled head screw passing

through a tapped hole in one of the end blocks ; however in case of the longer holders some form of

rapid adjustment is desirable which is achieved by providing a sliding block which can be clamped

to the side plates of the holder in any desired position by means of a knurled nut.

As already pointed, in order to increase the utility of slip gauges, it is essential that extensive

use be made of slip gauge accessories. These in conjunction with slip gauges are used for the

inspection of gauges and precision equipment; for the measurement of plug and ring gauges ; and

for marking out tools also. The beauty of these accessories is that these can be built up quickly and

used as a temporary limit gauge.

The various accessories may be listed out as follows :

(i) Measuringjaws.

(ii) Scribing and centre point.

(iii) Holders and base.

Fig. 2.176. Type A measuringjaws being

used for external measurement.

SUP GAUGES

Fig. 2.177. Type A measuringjaws being used

for internal measurement.

The slip gauge accessories are made from suitable

steel free from defects and hardened uniformly upto a

minimum hardness of 800 HV. The working surfaces of

the measuring faces of measuringjaws and the working

surface of the base are finished to obtain good wringing

surface without the use of any extraneous agent.

2.62.1.

Measuringjaws.

The measuringjaws are

always supplied in pairs. These are available in two types,

viz., for both external and internal measurements (Type

A) and the other type intended for external measurement

only (Type B).

Fig. 2.178. Type B measuringjaws intended

for external use only.

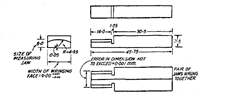

In Fig. 2.179 the most important dimension is the size of measuring jaws. This nominal size

is always engraved on the front end face of the jaw. In Fig. 2.179, the various other dimensions of

the measuring jaw have been shown for the measuring jaw size of 5.0 mm. Other sizes available

are 2.5 mm and 6.0 mm.

Fig. 2.179. All dimensions are in mm. Type A measuring Jaw.

It may be noted that in type B measuring jaw, no dimension is very important as it does not

come into measurement. The only important

item is the wringing face which should be flat

to within 0.0002 mm. This limit of accuracy

holds good for type A also. For type A jaw, the

nominal size of the jaw should be accurate to

within ± 0.0007 mm. When the pair of jaws are

wrung together the error in overall dimension

should not exceed + 0.0001 mm. The faces

perpendicular to the wringing faces should be

accurate to within 90° + 0.3′ from the wringing

face.

2.62.2.

Scribing and Centre

Points. These in conjunction with the

holder and slip gauges constitute very

accurate device for marking out pur-

poses. The scribing and centre points

are designed in such a way that when

they are used in combination, the

diameter of a final scribed circle does

not differ from twice the size of the

slip gauge combination inserted be-

tween the points by more than ± 0.05

mm. The scribing points and centre

are shown in Fig. 2.181 and Fig. 2.182

respectively.

In this case too, the wringing

face is very important and it should

be flat to within 0.0002 mm. The faces

perpendicular to wringing face should

be accurate to within 9° + 0.3′ from the

wringing face.

Fig. 2.180. Type B Measuring Jaw.

Fig. 2.182. Centre point.

2.62.3.

Holder.

The holders are available in three ranges, viz., 0 to 60 mm, 50 to 110 mm,

and 100 to 210 mm. These are made of suitable design for holding rigidly combination of slip gauges

within their range. The surface upon which the gauges are wrung should be flat to within 0.0001

mm and parallel to the base.

2.62.4.

Base (Refer Fig. 2.183).

It is made of robust construction and designed such that it

remains stable when used with the longest size holder. Suitable provision is made for the attachment

of the holder with the base in a position, normal with respect to the wringing surface of the base.

The wringing surface of the base should be flat to within 0.0002 mm and suitably relieved and an

air vent provided. The sides of the base are suitably relieved so as to provide convenient finger grip.

The surface upon which gauges are wrung should be flat within 0.0001 mm and parallel to the base

within 0.0002 mm. The normal height of the base should be in agreement with the dimension

marked on the base to within 0.0007 mm.