5.8.

Air gauging has rapidly increased during some past time due to the following important

characteristics:

(a) Very high amplifications are possible. It can be used to measure diameters, length,

squareness, parallelism, concentricity, taper, centre distance between holes and other

geometric conditions.

(b) As no physical contact is made either with the setting gauge or the part being

measured, there is no loss of accuracy because of gauge wear. For this reason, air spindle and

air snap gauges last very long. Also very soft parts which are easily scratched, can be gauged.

(c) Internal dimensions can be readily measured not only with respect to tolerance

boundaries but also geometric form. In other words, while measuring a bore it can reveal

complete story of size, taper, straightness, camber and bell mouth etc.

(d) It is independent of operator skill.

(e) High pressure air gauging can be done with cleansing of the parts which helps to

eliminate errors due to dirt and foreign matter.

(f) Gauging pressures can be kept sufficiently low to prevent part deflection.

(In general, high pressure gauges are suitable for those parts in which tolerances are

relatively large and low pressure air gauges are preferable for highly precise work.)

(g) Dimensional variations throughout the length of shaft or cylinder bore can be

explored for out of roundness, taperness, concertricity, regularity and similar conditions.

(h) Not only it measures the actual size, but it can also be used to salvage oversized

pieces for rework or to sort out for selective assembly, i.e., it is suitable both for variable

inspection (measurement of size) and attribute inspection (GO and NO GO) gauging and limits.

(i) The total life cost of the gauging heads in much less.

(j’) It is accurate, flexible, reliable, universal and speedy device for inspecting parts in

mass production.

(k) It is best suited for checking multiple dimensions and conditions on a part simul-

taneously in least possible time. It can be used for parts from 0.5 mm to 900 mm diameter

having tolerance of 0.05 mm or less. It can be easily used for on line measurement of parts as

they are being machined and take corrective actions.

5.8.1.

Systems of Pneumatic Gauges

. Based on the physical phenomena on which

the operation of pneumatic gauges is based, these may be classified as :

(i) Flow or velocity type, (ii) Back pressure type.

Flow or velocity type pneumatic gauges operate by sensing and indicating the momen-

tary rate of air flow. Flow could be sensed by a glass tube with tapered bore, mounted over a

graduated scale. Inside the bore a float is lifted by the air flow.

Velocity of air in velocity type pneumatic gauges can also be sensed by sensing the

velocity differential i.e., differential pressure across a venturi chamber. Such systems have

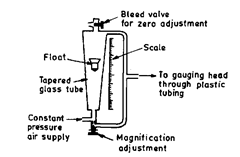

Fig. 5.32. Free flow air gauge.

quick response. These permit use of large clearance between nozzle and object surface,

resulting in reduced wear of the gauging members. There is less air consumption. Magnifica-

tion of the order of 500 to 5000 times is possible.

5.8.1.1.

Free Flow Air Gauges (Flow or velocity type).

In this case the compressed air

after the filtering and pressure reducing unit flows through a tapered glass tube containing a

small metal float and then through a plastic tube to the gauge head having two diametrically

opposed orifices for air escapement into atmosphere (Refer Fig. 5.32). The position of the tube

is dependent upon the amount of air flowing through the gauge head, which in turn is

dependent upon the clearance between the bore to be measured and the gauge head. Fig. 5.34

shows a curve between the air flow and the clearance between the part and the orifice in gauge

head.

Fig. 5.33. Zero and magnification adjustment

in flow type pneumatic comparator.

Fig. 5.34. Characteristic of air flow

versus clearance of flow.

The flow velocity type pneumatic comparator with zero adjustment and magnification

adjustment is shown in Fig. 5.33. Magnification can be changed by passing some of the air

supply, using a screw at the inlet to the tapered glass tube. The float can be zeroed by a bleed

valve installed at the top of the tube. Size is measured by the velocity of air in a tapered glass

tube which is measured by the height of the float in tube.

The straight portion of the curve is utilized for the measuring range. It provides high

amplification (10 : 1) and thus within the linear range, it is possible to read accurately upto

microns depending upon scale length, or classify the sizes quickly and accurately. The

amplification can be changed by quick change of tube, float and scale. Air gauge amplification

and range are based on the tooling and instrument standards of manufacturer. The amplifica-

tion and instrument are selected by considering the total tolerance spread and choosing the

instrument that covers the range. About 50 to 100 mm of column is usually allowed for the

actual tolerance spread.

In the gauging head, the air escapement orifices are recessed below its cylindrical

surface so that the orifices never contact the part being gauged. Thus the surface wear will not

affect the accuracy till it is worn down to orifice level. Also the orientation of gauge or the way

operator holds the gauge is of no consequence and same readings will be obtained for given

diameter. On the gauge, knobs are also provided for adjusting float position and calibration.

Air gauge is set by placing masters for maximum and minimum tolerances on spindle

alternatively and adjusting the float position for each master by turning the knurled knobs at

the base of the instrument.

Free-flow column type gauges are usually assembled together side by side and thus

multiple interrelated readings can be seen at a glance. This is the big advantage of air gauging

that the multiple dimensions and conditions can be inspected with great ease, accuracy and

speed.

Pneumatic circuits can be arranged to determine dimensional differences like taper

(comprising the diameter of bore at different points along a part), bore centre distance and also

to select parts to assemble to predetermined clearances or interference fits.

5.8.1.2.

Back Pressure Gauges.

The basic principle and the theory of pneumatic

gauging in the back pressure gauges is described below. (Refer Fig. 5.35)

Air from a constant pressure source

flows to the atmosphere through two orifices

Oc and Om in series.

P is the pressure upstream of the first

orifice andp is the pressure between the two

orifices, both measured with reference to

the atmospheric pressure as datum.

Fig. 5.35. Theory of pneumatic gauging.

The relationship between p and P will depend upon the relative sizes of the two orifices :

p being equal to P when Om is blocked and tends to zero as Om is increased indefinitely. Let C

be the geometrical area of Oe and M that of Om.

Then if p and C are kept constant while M is varied, the relationship between the

dimensionless quantitiesp/P and MIC is of the type shown in Fig. 5.36.

(The general form of this curve is quite well predicted by an analysis employing

Bernouli’s equation for flow of a compressible fluid.)

We are interested in linear portion of this curve.

For design purposes we follow an empirical approach which is based on an experimental

study at N.P.L. (London) of the relationship between pressures and orifices areas.

The characteristics of p/P and MIC are determined experimentally for pressure P

varying from 2 to 75 pounds per sq. inch (0.13 to 5 kg/cm2) and inspection of any one of these

shows that within the range 0.6p/P to 0.8p/P, the curve approximates to a straight line, the

equation for which mav be written as

![]()

Fig. 5.36. Characteristic curve of pneumatic gauge.

Examination of the family of curves shows that constant A, the intercept on the p/P axis is

closely constant over the range of pressures investigated and for practical purposes, the value

of A = 1.10 can be adopted for any value of P likely to be used.

The slobe b of straight portion characteristics is however not independent of P, its

numerical value decreases as P increases and the limiting values found in the investigation

are as under :

b = 0.6 when P = 0.13 kg/cm2

b = 0.4 when P = 5 kg/cm2.

5.8.1.3.

Area of escape orifice.

When

the clearance between the surface and the

nozzle face is zero, no air escapes from the

nozzle and the area of the escape orifice is zero.

When the clearance between the sur-

face and the nozzle face is very large, the area

of the escape orifice is ^ d2, where d is the

diameter of the nozzle.

Between these extremes, especially

where the clearance is small and where air

gauging can be employed, the area of the

escape orifice is n dl, that is, the area of the

curved surface of the cylinder shown in

Fig. 5.38.

5.8.1.4.

Range of linear measurement.

The condition 0.6 < p/P < 0.8 defines a

section of the characteristics which ex-

perimental investigation has shown to be

linear to within 1%.

Fig. 5.37. Experimentally determined

characteristics for different operating pressures.

Fig. 5.38. Area of the escape orifice.

Fig. 5.39. Range of linear measurement.

5.8.1.5. Pneumatic Sensitivity, i.e. how p varies by variation of M.

5.8.1.6.

Changing sensitivity (Magnification).

A plot of pressure against escape

orifice area for a number of different sizes of control orifice will show that sensitivity increases

as the diameter of the control orifice decreases, i.e., for small control orifices the change in

pressure is greater for a given change in escape orifice area. Utilising this property, it is

possible to set precisely the sensitivity (magnification) by incorporating a variable control

orifice.

5.8.1.7.

Overall Magnification.

In a practical pneumatic measuring apparatus the

area M will be associated with the measuring head and change in M will be the result of a

change in the dimension which is

being measured e.g. a change in the

separation L between nozzle and

surface (Fig. 5.40).

The overall magnification of

the apparatus, i.e. the ratio of the

linear movement of the pointer or

index of the pressure measuring in-

strument to the change in the

Fig. 5.40. Variation of M w.r.t. L.

![]()

This condition requires the measuring head to be correctly designed. The final escape-

ment of the air from the nozzle to the atmosphere is taken as being through an area of the

curved surface of the cylinder of length L and diameter D, where L is the separation between

the nozzle surface and the surface to be gauged and D is the internal diameter of the nozzle.

5.8.1.8.

Response Speed.

For a back pressure system the speed of response is not as

fast as for free-flow type, because some time is required for the pressure to build up. The speed

of response becomes of concern when the gauginghead is separated from indicating instrument

by long distance.

A pneumatic measuring system will not correctly measure displacements of frequency

greater than about 2 cycles/second, because of its slow speed of response. The response is

considerably slower compared to the electrical system because of the following reasons.

Between the control orifice and the measuring head, there exists a closed volume associated

with the measuring instrument used to measure the pressure p. A dimensional change, e.g., a

displacement of the surface alters the flow so changing the pressure p. The time needed to

establish the new value of p depends on the total volume and on the rate of air flow into and

out of it. The latter in turn depends upon the operating pressure P and the size of the control

orifice and orifice in the measuring head. These orifices are related in size and determine the

pneumatic sensitivity, the smaller orifices (corresponding to the higher magnification), having

a more restrictive effect on the air flow and so slowing the response.

It has been examined theoretically and experimentally that response is slowed by using

a large operating pressure P and a large volume, but by these high sensitivity (magnification)

is obtained. In any practical pneumatic measuring system, the overall response will be

influenced by dynamic characteristics of the pressure measuring device. Thus it follows that

the use of a low operating pressure will not improve the overall response if a low pressure

measuring device of slow response is used to measure the pressure changes. High sensitivity

will inevitably be associated with slow response and the only factor left to the designer is the

volume, which should be made as small as possible for quick response.

Since gauge is always located at some distance from the control unit, the effect of

variations in the gauging position does not reach the control unit instantaneously, though the

size variations of the object will promptly affect the air flow at nozzles. The time gap between

the sensing and indication is known as response time which depends upon : Length of air line

between the nozzles and indicator, (ii) type of gauge system, and (Hi) the design of control unit.

Response in case of flow type pneumatic gauges is relatively quick. Response in case of back

pressure gauges is slow, the compressibility of air also contributing to the delayed transmission

of the variations sensed at the nozzles.

Response time of back pressure type pneumatic gauges can be improved by utilising

following devices :

(i) Using filled system pressure gauge, thereby reducing volume of air.

(ii) Restricting the unimpeded escape of air through the orifices when the gauging head

is not in operation, by using a spring-charged cover sleeve around the gauge head.

(iii) Counteracting the unrestricted air escape by an auxiliary air supply relay whose

operation automatically discontinues as soon as a specific back pressure develops during the

actual gauging process.

(iv) Using a high speed relay to compensate for additions to the volume of the instrument

system.

5.8.1.9.

Zero Setting.

It is accomplished by means of a bleed valve and consists in

adjusting the indicating element of the gauge to that marking on the scale which was selected

to signal coincident with the nominal limit size represented by a setting master.

5.8.1.10.

Datum Control.

If means be provided to change the pressure in the cavity

(between control orifice and measuring orifice) using a variable bleed to atmosphere, a datum

or zero can be provided which varies the pressure ‘p’ when the escape orifice area remains

fixed. This addition to a circuit provides means of accommodating small differences which

inevitably occur in the manufacture of gauge heads. Limited use of a datum control in the form

of a bleed to atmosphere has an insignificant effect on linearity.

However, this system depends highly upon the pressure regulator to maintain the

supply pressure within very close pressure limits. Thus the pressure regulator is a critical

component in this circuit. This problem is overcome in differential back pressure circuit in

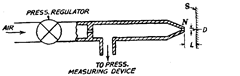

Fig. 5.41. Practical back pressure circuit.

which accuracy is maintained regardless of some variation in the regulator performance which

controls supply pressure. Fig. 5.42 shows a practical flow-responsive system which is in

common use. This system employs variable orifices for sensitivity and datum control.

Fig. 5.42. Practical flow responsive system.

Fig. 5.43. Plug for pneumatic comparator.

5.8.1.11. Am

plification Adjustment.

This permits different range of gauge indica-

tions on same scale length and is carried out with a precision valve of the control unit. Both

zero setting and amplification adjustment should be checked from time to time depending upon

experience.

5.8.1.12.

Jet Recession.

It has already been seen that when the surface being measured

is very close to the nozzle face, equal increments of change in clearance do not produce equal

increments of pressure change. The system is not linear under these conditions.

Because of this the faces of the jets on air plug gauges are ground below the body

diameter of the plug as shown Fig. 5.43. This grinding back is called jet recession and it is the

means by which the non-linear portion at the high pressure (low flow), end of the pres-

sure/clearance curves is avoided.

5.8.1.13.

Measurement of Bore. [Refer Fig. 5.44 (a) and (6)]

In the above discussion we have as-

sumed a jet separation of the nozzle from the

flat surface. This is also applicable to measure-

ment of bore, where L is modified as :

L = Lx + L2, Lx – Radial gap for one jet

and L2 = Radial gap for other jet.

Theoretically Li should be equal to L2,

but even if L\ * L2 the back pressure would be

closely equal to that corresponding to the con-

dition L1 = L2 = L/2. This is a big advantage as

operator need not be very meticulous about

orientation of the measuring head in the bore,

and thus the readings from operator to

operator will be uniform as they do not depend

upon a high degree of operator skill or sense of

feel.

5.8.1.14.

Measuring Heads Measuring heads fall under two categories,

viz. direct head [Fig. 5.45 (a) and

(6)1, and indirect or contact head [Fig. 5.45 (c)

and (d)]. Tapered nose type direct head [Fig.

5.45 (a)] is quite popular as it permits easy

access in constricted measuring conditions.

The ratio of land diameter (overall diameter at

tapered small end) compared to jet diameter is

twice in size. Bigger ratio would affect the escapement of air and the characteristics of the

system.

Head at Fig. 5.45 (b) provides good protection to the nozzle due to incorporation of guard

ring and escapement holes. In the case of indirect measuring heads, the jet is protected from

accidental damage. The size of air escapement is controlled by a needle valve or flat plate [Fig.

5.45 (c) and (d) respectively] which move due to movement of measuring plunger. By changing

the taper of needle valve, the range of measurement can be changed. Parabolic needle provides

linear response. Fig. 5.45 (e) shows the plug gauge used for measurement of diameter, lobing,

taper etc. The measuring side is made somewhat smaller than the bore so that it enters much

more conveniently.

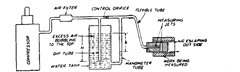

5.8.2.

Solex Pneumatic Gauge. (Fig. 5.46).

This instrument is produced commercially

by Solex Air Gauges Ltd. This is generally designed for internal measurement, but with

suitable measuring head it can be used for external gauging also.

It is obvious from the equation for sensitivity that in order that sensitivity (magnifica-

tion) remains constant, the supply pressure P must be constant.

Thus it is necessary to have a simple pressure regulator which may control the pressure

of air from the normal supply line, and if necessary the pressure might be reduced also. The

arrangement used in Solex gauge is to pass the high pressure air after filtering, through a flow

valve. There is a tank in which water is filled upto a certain level and a dip tube is immersed

into it upto a depth corresponding to air pressure required. In Fig. 5.46, it is represented by

H. Since air is sent at higher pressure than required one, some air will leak out from the dig

tube and bubble out of water and the air

moving towards control orifice will be at

desired constant pressure H.

Now-a-days diaphragm type

pressure regulators are readily avail-

able in the market and they are better

for regulating the pressure than the

above device. The air at reduced pres-

sure then passes through the control

orifice and escapes from the measuring

jets. The back pressure in the circuit is

indicated by the head of water displaced

in the manometer tube. The tube is

graduated linearly to show changes in

pressure resulting from changes in in-

ternal diameter of the work measured.

This instrument is capable of measur-

ing to the accuracy of microns.

It is very obvious from Fig. 5.46

that the diameter being measured at

any instant is corresponding to the por-

tion against two jets. Now to find the

concentricity (roundness of any job at

any section), the workpiece may be

revolved around measuring gauge. If no

change in reading is there, then it is

perfectly round hole. Similarly the

diameter can be noted down at several

places along the length of bore and thus

tapering of hole is determined. This

method is, therefore, best suited for

measuring roundness and taperness of

cylinder bores and gun barrel bores.

By having suitable measuring

head this can be used for external gaug-

ing, and head in this case will be as

(a), (6) Direct heads (c) Forward head

(d) Reverse head (e) Plug gauge.

Fig. 5.45. Measuring heads.

Fig. 5.46. Solex Air Gauge.

shown in Fig. 5.47. This can best reveal any lobing effect

also. It is also possible to have arrangement to measure

the length of slip gauge by having the flat table and one

jet at the top.

5.8.2.1.

Overall Magnification and Range.

From equation dpIdM = 0.40 P/Mc, the pneumatic sen-

sitivity of a pneumatic measuring apparatus can be

increased by increasing the operating pressure P, but

![]()

controlled by the length of scale of pressure measuring

instrument corresponding to pressure changes from 0 to

P. If this scale length is to remain of convenient mag-

nitude, increasing the operating pressure is not a

suitable method for improving the overall magnification. The only effective method for

obtaining the higher magnification is, therefore, to reduce average separation between nozzle

and surface, which at the same time, of course, reduces the range of linear measurement.

5.8.2.2.

Limitations of empirical approach.

From the view-point of air flow, the

effective area of an orifice is not usually identical with its geometrical area. If two orifices are

made by producing holes of identical geometrical area in two thin discs, their effective areas

may be appreciably different as a result of edge effects on the air flow arising at the peripheries

of the orifices. Again the relationship between effective area and geometrical area is unlikely

to be the same for air flow through an orifice and the jet of air from a nozzle. In the experimental

determination of the p/P, MIC characteristics the value of M and C used were the geometrical

areas of orifices Om and Oc. Therefore due to effective area being different from the geometrical

area, the empirical equation obtained by analysing these characteristics would not be expected

to provide a completely accurate numerical forecast of performance.

Nevertheless, experience has shown that they do give a first approximation sufficiently

reliable to permit the required performance to be obtained by a single-step corrective adjust-

ment of the control orifice.

5.8.3.

Differential Comparators.

A later development brought out the balanced

circuit type of air-gauge. In this equipment a differential pressure indicating mechanism,

connected across the two air-paths and a built-in gauge zeroing valve is provided. Such a

balanced circuit is shown schematically in Fig. 5.48. An air gauge based on this balanced circuit

is called ‘Differential Comparator’.

Three equally spaced measuring orifices

(jets) reveal any lobbing effect also.

Fig. 5.47

Fig. 5.48. Differential Circuit.

Compressed air from a suitable source, after passing through air-drier and filter is

regulated for constant pressure by a pressure regulator. Now the air flows into two channels,

each of which has a control orifice Ocl and Oc2 (control orifices are also called master jets).

From the control orifice Ocl, air flows to the measuring head where it meets further restriction

of the workpiece or the master settings. The restriction of the workpiece builds up back

pressure as explained earlier. At the same time, other half of the air is flowing through the

other control orifice Oc2 to the reference jet Om. By closing or opening the valve of reference jet

Om, the pressure in the space between Oc2 and Om is regulated (adjusted) to match the back

pressure from the measuring jets, which is sensed by the pressure indicating device fitted

across the two channels as shown. At this adjustment of the reference jet, the pressure indicator

would indicate equal pressure in the two channels and hence read zero on the scale. This zero

setting (adjusting of reference jet Om) is done with master workpiece whose dimension is exact

nominal size.

Now the variation of the dimension at the measuring head would cause change of

back-pressure in channel A. This pressure would be different from the mean pressure which

has been already set in the channel B (by reference jet). Now the difference of pressure of the

two channels would be indicated by the pressure indicating device which can be directly

calibrated in terms of variation of dimension from the mean dimensions. Hence the instrument

based on the measurement of differential pressure is called Differential Comparator.

If the dimension causes a decrease in gap L as compared to La, this in turn decreases

M and hence increasing back pressure in channel A and vice versa. In these cases the pressure

indicator would show readings on both sides of zero corresponding to ± deviation from master

setting.

5.8.3.1.

Advantages of Differential Circuit over Single Channel Circuit,

(i) Effect

of change of operating pressure P. The operating pressure may vary slightly from the designed

value. It can be shown that error due to change of pressure would be 0.6 to 0.8 times the change

in pressure in single channel in case of differential circuit the error would be 0.1 times the

change in pressure.

(ii) Zero setting of master gauge is an extra advantage.

(iii) Rectification for control orifice. In a single channel system, the practical limitations

may not give the perfectly correct and accurate dimension of the control orifice as designed.

Sometimes it may go out of the useful range of the design and it may have to be discarded.

Therefore, in order to avoid the error of manufacture and also to take into account the

fact that the geometrical area is different from the effective area, we need a needle valve so

that area may be adjusted accordingly.

But in the differential circuit which incorporates a needle zero adjusting valve, the

off-set of the actual size of the control orifice from the designed value can be nullified by

adjusting this valve.

5.8.4.

Non contact and Contact Type Pneumatic Gauging Elements.

Non contact

tooling is best suited for automatic gauging applications because of the advantages of no

contact, clearing of oil or foreign particles from gauging area, etc.

In the case of non-contact air gauge tooling, only the air coming out of the air escapement

orifice touches the part to be measured, the air flow rate depending on the cross-sectional area

of the jet and the clearance between the jet and the part to be measured. It may have a single

jet, two diametrically opposite jets or more evenly spaced jets. Single open-jet tooling can be

used for checking outside diameter, height, depth, straightness, squareness, etc. and Fig. 5.49

shows a few of such applications. Dual jet techniques can be applied for determining true

diameter, out or round, bell mouth, thick-

ness, etc. The various gauges may be

designed either for presenting the gauges

to part or vice versa.

Many modern mechanical as-

semblies demand that holes should be

closely controlled for straightness as well

as diameter. An air plug gauge for

gauging hole straightness is shown in

Fig. 5.50.

In the contact tooling, a mechani-

cal member is incorporated between the

air escapement orifice and the part to be

measured. The air flow from the jet chan-

ges due to displacement of this mechani-

cal member when it contacts the part.

The mechanical member could be a ball,

lever, plunger or blade. A big advantage

of contact type air gauge is that a much

bigger measuring range (upto 2.5 mm) is

possible i.e. it is suitable for wide range

of gauging. Another advantage is that it

eliminates surface roughness from

size. It may be mentioned that open

jet type method would be subject to

error for rough surfaces because it

measures a combination of size and

surface finish ; further its range of

measurement is limited. Ball jet

spindle gives a point reading rather

than the average over a small area

and is best suited for gauging inside

diameter of soft or porous parts and

for rough bores. Leaf jet spindle can

be used for checking laminated bores, blind holes in which keyways etc. do not permit the use

of open jet spindles at extreme bottom of blind holes etc. Blade jet spindles are used for

inspecting gun bores in which oil grooves, or slots do not permit the use of ball jet or leaf jet

spindles.

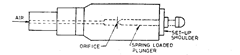

Fig. 5.51 shows a small plunger type air gauging cartridge which is highly efficient

size-sensing element for wide range of gauging, tooling, fixturing, and machine control

applications. It essentially consists of a spring loaded plunger. The spring tries to keep the

Fig. 5.49. Applications of single open jet tooling.

Fig. 5.50. Straightness measuring gauge.

Fig. 5.51. Air Cartridge.

plunger outwards and when the part to be measured comes in contact with it or it comes in

contact with the part it moves in and at the end restricts the orifice, thereby increasing the

back pressure. The maximum and minimum limits of the plunger movement can be set with

the help of masters. Such cartridges can be secured in gauging position on various types of

fixtures and used for measurements like height, depth, flatness, concentricity, squareness,

inside/outside diameter, etc.

Fig. 5.52 shows the same principle used in a test indicator which is very efficient for

several applications. It has a tiny stylus capable of entering into small holes, keyways, slots

Fig. 5.52. Pneumatic test indicator.

etc. and its movement causes the tapered end to act as a precision valve stem to regulate the

amount of air flowing through an orifice. It is free of hysteresis or lag or drag in indications

when the stylus is moved in any direction across the workpiece.

The contact type adjustable spindle kits and adjustable air snap gauges available in

market are found to be very suitable for handling new designs, altered dimensions and various

other varied applications.

5.8.5.

Indirect Pneumatic Gauging Devices.

The open jet has the disadvantage of

small measuring range. It can be overcome by using indirect pneumatic gauging devices by

using a gauging cartridge. Such cartridge employs a contacting stylus, the inner end of which

is tapered and forms the restriction in an escape orifice. The position of the stylus and

consequently the position of the taper in the orifice causes changes in the area of the orifice.

Changes in the rate of taper change the measuring range of the cartridge. Measuring ranges

upto 3 mm can be obtained with this type of cartridge.

5.8.6.

Air gauging with electronic sensors.

Air gauging system operate on either

low or high air pressure. While low pressure systems have greater sensitivity, quicker response

time and minimal distortion when measuring flexible components, the high pressure systems

are self cleaning type and have a large measuring range. Basically air gauging comprises air

jet gauges—such as ring or plug, and air operated liquid columns for multi-dimensional

measurement.

Now-a-days electronic flowmeters are used in place of air operated liquid columns. They

have the advantage of measuring flow of air with the added benefit of electronic display. Such

instruments can easily have 2 or 3-range selection to give an extra magnification factor.

Tolerance limit lights can be incorporated to indicate whether parts are inside or outside

manufacturing tolerances. Response time increases many folds.

The versatility of air gauging is enhanced by the wide range of measuring tools like 2

and 3 jet non-contact air plug gauges, setting rings and air jet ring gauges.

5.8.7.

Multi-gauging Systems.

Multi-gauging systems are used to measure a number

of dimensions simultaneously. Parts to be gauged are compared with a setting master which

simulates the component. The features gauged could be external/internal diameters, lengths,

straightness, squareness, ovality, run-out of faces, etc. The measuring head gauging fixture is

specifically designed to suit the component to be measured and may be completely special or

it may be built using a series of modular elements. It contains the means for sensing the

dimensional difference between the components and the master which may take the form of

mechanical or electronic probes or air jets connected to the means for amplifying the difference.

The amplifying and display of readings may take the form of dial gauges or some form

of electronic or air/electronic system.

Display may be analogue, digital or graphic and may be augmented by out of tolerance

indication.

Using electronic differential methods, the relationship between different features can

be related to a common datum.

The choice of system depends on number of factors like initial cost, dimensional

tolerances of the features to be measured, complexity of the component, complexity of the

features to be measured, number of features to be measured, speed of measurement required,

skill or otherwise of the user.

The reasons affecting the choice of displays are given below :

(i) Pointer displays—best where a rapid check of run-out or concentricity is required.

(ii) Columns—natural choice where a considerable number of dimensions are involved.

These are fastest and most convenient form of displaying the readings for every

dimension.

(iii) Digital—provides high accuracy over a longer measuring range and best for situa-

tions where it is required to work in drawing dimensions. Can be viewed without strain over

longer distances.

(iv) Graphic on VDU—the most sophisticated display essential when statistical process

control systems are employed.

Systems capable of dealing with very large number of inter-related dimensions can be

developed.

Automatic inspection machines incorporate both automated loading hopper, magazine,

pick and place robot and—automated segregation of inspected components. Automatic inspec-

tion is essential where the complexity of the component is such that manual methods can not

achieve the desired levels of accuracy.

The results of inspection could be fed to electronic computer based system which may

also control the machine operation. The use of such computer based processing also allows the

results obtained to provide a wide range of control facilities including feedback for control of

the manufacturing process.

Coordinate measuring machines accommodate multidimensional inspection by using a

single point contact to take successive measurements over the component profile. The contact

movement and processing of the dimensional information is under computer control, which

can also provide similar facilities to those offered by multi-point gauging.