8.7.

The first set of combination of angle gauges was devised by Dr. Tomlinson of N.P.L.

With thirteen separate gauges used in conjunction with one square block and one parallel

straight-edge, it is possible to set up any angle to the nearest 3″. In the same way, as slip gauges

are built up to give a linear dimen-

sion, the angle gauges can be build

up to give a required angle. Angle

gauges are made of hardened steel

and seasoned carefully to ensure

permanence of angular accuracy,

and the measuring faces are lapped

and polished to a high degree of

accuracy and flatness like slip

gauges. These gauges are about 3

inch (76.2 mm) long, 5/8 inch (15.87

mm) wide with their faces lapped to

within 0.0002 mm and s angle

between the two ends to ± 2 seconds.

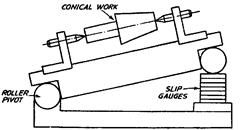

Fig. 8.20. Sine Centre.

The secret of this system in having any angle in step of 3″ is the adoption of a mathematical

series of the values of the angles of various gauges of the set. The thirteen gauges can be divided

into three series ; degrees, minutes and fractions of a minute. The gauges available in first

series are of angle 1°, 3°, 9°, 27° and 41°. Second series comprises 1′, 3′, 9′ and 27′ angle gauges

and this series has 0.05′, 0.1′, 0.3′ and 0.5′ (or 3″, 6″, 18″ and 30″) angle gauges. All these angle

gauges in combination can be added or subtracted, thus, making a large number of combina-

tions possible. There are two sets of gauges available, designated as A and B. The standard A

contains all the above 13 gauges. Standard B contains only 12 gauges and does not have the

0.05′ angle gauge.

Direct combination enables computation of any angle upto 81° 40.9′ and angles larger

than this can be made up with the help of the square block. However, an additional gauge of

9° can also be supplied with the set to obtain a full 90° angle without the use of the square.

Fig. 8.21 illustrates how the gauges can be used in addition and subtraction. The procedure

used for making various angles is as follows : e.g. say, we have to build up an angle of 57°

38′ 9″.

Fig. 8.21. Angle gauges can be used in addition and subtraction mode.

(a) Die insert

(b) All gauges added. Total angle

= 37° 9′ 18″ (Not to scale)

(c) Angle set up = 27° minus

9′ 30″ = 26° 50′ 30″

Fig. 8.22

Thus it is seen that any angle could be made up but the block formed by the combination

of a number of these gauges is rather bulky and, therefore, cannot the always directly applied

to the work. But these gauges being used as reference and taking the aid of other angle

measuring devices will be a good proposal at many places.

Angle gauge blocks seem to lack the requisites for use as primary standards because

errors are easily compounded when angle blocks are wrung in combination. Further the

absolute verification of angle blocks is usually dependent on some other primary standard.

8.7.1.

Uses of angle gauges

(i) Direct use of angle gauges to measure the angle in the die insert.

To test the accuracy of the angle in the die insert, the insert is placed against an

illuminated glass surface plate or in front of an inspection light box. The combination of angle

gauges is so adjusted and the built-up combination of angle gauges carefully inserted in

position so that no white light can be seen between the gauge faces and die faces. It may be

noted that when all the engraved Vs on the angle gauges are in the same line, all angles are

added up. In case some engraved Vs on angle gauges are on other side, those angles are

subtracted.

(ii) Use of angle gauges with

square plate.

As already indicated, the use of

square plate increases the versatility of

the application of angle gauges. Generally,

the square plate has its 90° angles

guaranteed to within 2 seconds of arc.

Where very high degree of accuracy is

required, the four corners of the square

plate are numbered as A, B, C and D, and

a test certificate is issued with each set of

angle gauges, giving the measured angle

of each corner. Fig. 8.23 shows a set up to

test the angle of V-gauge whose included

angle is 102°. The whole set up is placed

against an illuminated glass surface

plate. It may be noted that the use of slip

gauges has to be made in order to

facilitate the testing.

Fig. 8.23. Set-up for checking V-gauge having

included angle 102°.

So far, we have used angle gauges to obtain a visual comparison of an angular dimension

under test. It has also been realised that though it may be possible to obtain good results but

it is difficult to give an estimate of the actual angular error. For very precise angular

measurements, angle gauges are used in conjunction with angle dekkor described later in

Art. 8.10.9.

8.7.2.

Manufacture and Calibration of angle gauges.

First the angle gauge is

approximately machined to the desired shape, hardened by quenching, tempered and

stabilised. The non-gauging sides of the block are then ground to obtain uniform thickness,

and made flat and parallel by

lapping operation. One gauging

face is also lapped flat and made

square to the lapped non-gaug-

ing sides. The simple method

for manufacture of 27° and 9°

angle gauges is described to ex-

plain the principle. This method

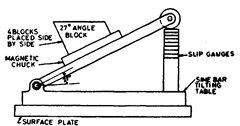

requires the use of sine bar tilt-

ing table, slip gauges and mag-

netic chuck. The set up is shown

in Fig. 8.24, in which the sine

table is set at 27° and magnetic

chuck fixed on tilting table sur-

face, and the four 27° angle

Fig. 8.24. Set-up for grinding 27° angle gauge blocks.

gauge blocks wrung side by side on to the magnetic chuck. Their upper surfaces are then surface

ground parallel to the base of the table, thereby producing four blocks, of exactly equal angle

which are again checked for accuracy of angle. In similar manner, 9° blanks are also finished

and the three 9° blocks are wrung with 27° block in opposite direction so as to form a block

with parallel sides, as shown in Fig. 8.25.

This combination of block is checked for error in

parallelism. Thus error of each 9° block relative to 27° block

will be one-third of the error noted in parallelism of com-

posite block of Fig. 8.25. All the blocks of 9° are again lapped

together till the error in parallelism is equal to the permis-

sible value. In this way, all the gauges would be of equal

angle but not necessarily of 9° and 27° exactly. The actual

error in individual block from its true angle can be got rid

of by the following procedure. Three blocks of 2 7° and one 9°

block are wrung together to form a composite block of 90°

and its squareness is tested by any of the method described

in Art. 7.8.2 and the error noted down. On of the 27° angle

Fig. 8.25. Combination of 3 blocks

of 9° and one block of 27° so as

to form parallel set of blocks.

block is then lapped to reduce its error to zero by making it similar to a standard angle gauge

whose actual angle is known. In this process, the gauge being manufactured (lapped) is wrung

with standard 27° angle gauge and error in parallelism noted and it is further lapped till error

in parallelism becomes zero. Other 27° blocks are also corrected in same way individually. All

the four 27° blocks are then placed on magnetic chuck and it is ensured that the outer faces of

all are in one true plane by lapping them together carefully. Same procedure is followed for 9°

blocks also. Finally 3 blocks of 27° and one block of 9° are again wrung to make a combination

of 90° block which is tested for squareness by autocollimator method as described in Art. 7.8.2.3.

8.7.3.

Calibration of angle gauges by interferometry.

By this method, precision of the order of 0.1″ of

arc in angle measurement is possible. It is assumed that

these gauges have high degree of flatness on their working

surfaces. The gauge length interferometer is used for this

purpose. The angle gauge is wrung on the platen carefully

(Fig 8.26). On viewing through the eyepiece, two inter-

ference patterns are seen consisting of straight, parallel and

equally spaced fringes. But due to angle between the two

surfaces, the pitch of the two sets of fringes is different. Let

there be p fringes above the platen and q fringes above the

gauge on same length I.

Then 8 = 0! – G2 = X (p-q)/2l

where K is the wavelength of light used. There is however a

limitation that angle upto only one minute can be measured

directly by this method. Therefore, first the gauges of third

series must be inspected and then others by combiiiations

and adjusting optical flat to same angle.