ABSTRACT

This article studies the effect of different sterilization techniques on structure, thermal and time-dependent mechanical properties of polyamide 6 materials. We used two different types of polyamide 6 material: conventional polyamide 6 with monomodal molecular mass distribution and modified with bimodal one. Samples were prepared and properly shaped in order to observe the mentioned features before and after sterilization with three different techniques, namely sterilization with autoclave, ethylene oxide, and hydrogen peroxide plasma. Optical microscopy, differential scanning calorimetry and torsional creep testing were used for the properties investigation. As a main criterion to evaluate the effect of sterilization durability of materials was used.

There was observed significant difference between monomodal and bimodal PA6 materials regarding their morphology and consequently thermal and mechanical properties: bimodal material exhibits more complex structure than chemically identical monomodal one.

The results of analysis did not show considerable influence on both materials structure and thermal properties. However, there was observed strong effect on creep behavior. The most significant effect is detected for monomodal material sterilized by ethylene oxide, while creep compliance of the bimodal material did not change much due to any of applied sterilization techniques. Thus, modification the complexity of the material inherent structure improves sensitivity to sterilization.

KEYWORDS: sterilization, ethylene oxide, hydrogen peroxide plasma, autoclave, polymer, polyamide, nylon, bimodal molecular mass distribution, time-dependent mechanical properties, creep compliance.

INTRODUCTION

Nowadays the use of polymeric materials in medicine is growing steadily. Polymers occupy leading position in industry and commonly applied for medical equipment and devices, instruments, packaging, sutures etc. On top of it all, recent years’ research showed that polymers have a number of advantages for wide application in implantology branch. Compared to metals and ceramics polymeric materials provide better mechanical compatibility, allow bone growing into the implant and may be absorbed by body over time. For the most part, polymers are chemically inert, not toxic, exhibit good hydrophilic properties. Finally, they provide reasonable cost, safety, lighter weight and manufacturability. Thus, polymers are currently replacing traditional materials used for implants production.

It was reported on possible use of different polymers for dental implants [1]. In this work we propose the use of polyamide 6 (PA6) as an option. This material is known to be biocompatible, exhibits good time- and temperature stability, has excellent mechanical properties and exceptional capability of moisture absorption. In addition, use of PA has already been introduced into dentistry practice in form of sutures material and dentures production. Another reason is that current progress in science allows production of so-called intelligent polyamides (I-PA) with modified initial kinetics. Such modification leads to formation of different structure and, consequently, to different macroscopic properties of final product. Thus, deliberate modification of material inherent structure allows tailoring unique properties which can prove better behavior under certain conditions than standard chemically identical materials [2].

Sterilization is essential for all implanted materials. However, currently used methods of sterilization alter properties of polymers and consequently have influence on their functionality and durability [3]. Furthermore, as sterilization affects surface properties it may change biocompatibility of the product [4] what is crucial for medical applications. Unfortunately, methods of sterilization are paid relatively little attention in respect to their effect on materials used, and existing sterilization techniques assumed to be appropriate for any product. It is, therefore, important to understand how the polymer will behave post-sterilization [5], with respect to the technique used at that.

Currently the following techniques are mainly used in medical branch: y-irradiation, dry heat, autoclave, ethylene oxide (EtO) and hydrogene peroxide (H2O2) plasma. In this paper the effect of three last mentioned methods on PA6 with monomodal and bimodal molecular mass distribution is studied. Characterization of materials was performed in respect to their structure, thermal and time-dependent mechanical properties.

MATERIALS

Materials tested on sterilization effect were commercially available PA6 BS400N and multimodal I-PA6, described by Emri et. al [2], both produced by BASF. Conventional PA6 has monomodal molecular mass distribution, whereas the new I-PA6 has bimodal one. The average molecular weight of both materials is roughly the same.

Fig. 1 Morphology of non-sterilized monomodal PA6 (a) and bimodal I-PA6 (b) Axioskop 2 MAT (Carl Zeiss), polarized transmitted light, 200x

Structure of both materials, observed by means of optical microscopy, is shown in the Fig. 1. By comparison one may infer significant difference in morphology of non-sterilized standard material and modified one, prepared by the same technology. In the case of monomodal PA6 obtained image indicates formation of coarse spherulites that can be observed as Maltese cross patterns (Fig. 1a), while bimodal I-PA6 forms homogeneous fine grain structure when exposed to the same processing conditions (Fig. 1b).

From both types of polyamide materials samples were prepared to observe changes in the properties of interest after exposure to three different sterilization techniques: autoclave sterilization, EtO sterilization, and H2O2 plasma sterilization.

SAMPLES PREPARATION

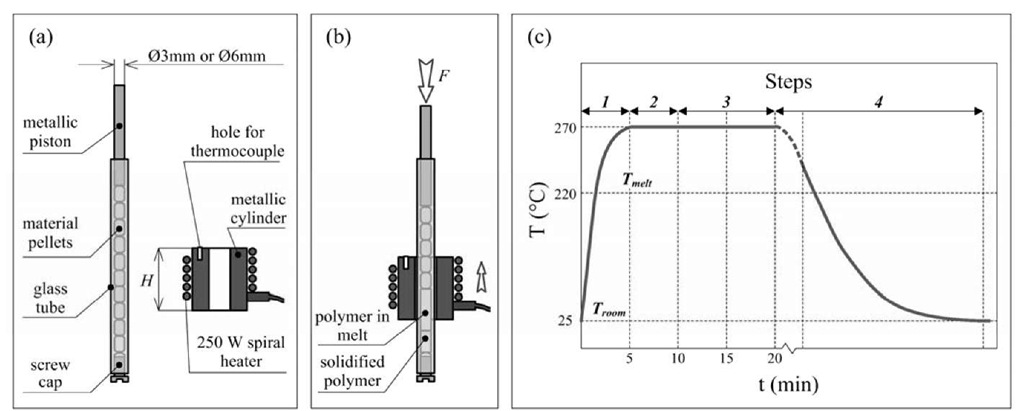

From both types of PA6 cylindrical samples were prepared using the equipment illustrated in Fig. 2a by means of compression molding procedure, which temperature profile is shown in Fig. 2c. PA granules were placed in a cylindrical glass tube with an inner diameter of 3mm for creep test and 6mm for structural and thermal analysis. Following this, the heater was placed on the bottom of the glass tube, and a pressure was applied from above to prevent material adhesion to the tube inner surface (Fig. 2b). The heater temperature was maintained at 270°C, and it was moved up at a relatively slow rate (2.25 mm/min), giving the pellets enough time to melt. As a consequence, the applied pressure pushed above pellets into the melt, removing any possible trapped air. After sliding over the whole tube, the heater was removed, and the specimen was left to cool down naturally to room temperature.

Fig. 2 Scheme of cylindrical rods preparation by compression molding procedure

Finally, received cylindrical rods were extracted from the glass tube. For creep tests the cylinders were cut down to length 60mm in order to fix the sample for creep measurement. For optical microscopy and DSC analysis the 6mm in diameter rods were cut using the Rotary Microtome HM 355 S (MICROM International GmbH) into slices with 10 |m and 100 |m thickness, respectively.

METHODS OF STERILIZATION

The listed sterilization techniques were applied to obtained rod specimens and slices, which before the sterilization itself were put and sealed in sterilization bags.

Steam sterilization was realized in autoclave EUROKLAV 23-VS (Melag, Germany) for 75 min at 121 °C and 0.1 MPa. After the procedure the specimens were allowed to dry for 2 hours.

EtO sterilization was performed in DLOG chamber (De-Lama, Italy). The samples were sterilized for 1 hour, then they were aerated for 2 hours inside of the chamber and 10 days before further investigation.

H2O2 plasma sterilization was performed on STERRAD 100S system (Johnson & Johnson, USA). The operation temperature and time were 50°C and 55 min, respectively.

METHODS OF CHARACTERIZATION

OPTICAL MICROSCOPY

The morphology of PA samples was studied with an optical microscope Axioscop 2 MAT (Carl Zeiss, Germany), appointed with polarized light equipment. Prepared slices with thickness ~10^m were observed with polarized transmitted light under magnification of 200-x at room temperature. The analyzer was installed perpendicularly to polarizer. All the pictures were taken by AxioCam HRc digital camera with resolution 1300×1030 pixels.

DIFFERENTIAL SCANNING CALORIMETRY

Thermal properties of investigated samples were defined by DSC. All measurements were carried out on DSC7 instrument, produced by Perkin Elmer, USA, in nitrogen atmosphere at a flow rate 50ml/min. Mass of used specimens ranged from 5 to 7mg. Each test was performed at a nominal scanning rate of 20°/min in the following order: holding the sample at 0°C for 10min, heating from 0 to 280°C, holding at 280°C for 2min, cooling from 280 to 0°C, holding at 0°C for 10 min, heating from 0 to 280°C. For each specimen we performed 6 repetitions of measurement. All reported results are averaged over the number of samples examined.

To determine temperature and enthalpy of crystallization the cooling curve of the first scan was used, whereas, to determine melting temperature and enthalpy of melting the second scan heating curve was used. Melting and crystallization temperatures were defined as the melting and crystallization peak temperatures, respectively. Enthalpies of transitions were obtained by integrating the area under the corresponding peaks. The materials crystallinity, c, was defined as a ratio between experimental heat of fusion, AHm, and the theoretical value for 100% crystalline![]() , which is 230 J/g:

, which is 230 J/g:

TORSIONAL CREEP MEASUREMENTS

Since properties of polymers may considerably change with time, which means that functionality and stability of polymeric products may be affected over time of their exploitation, we investigated how the sterilization affects mono- and bimodal polyamide time-dependent (long term) mechanical properties [6, 7]. In order to characterize the effect of different sterilization techniques on materials’ long-term behavior, shear creep compliance measurements were performed according to the procedure described below.

Shear creep measurements of investigated PA materials were performed with the Apparatus for Torsional Creep Measurements that has been designed and manufactured at the Centre for Experimental Mechanics at the University of Ljubljana, Slovenia [8 - 12]. Iitial part of the creep measuring procedure started with the annealing phase at higher temperature (110°C) that should erase mechanical stress-strain history of the material. After the annealing phase the torsional creep measurements were performed in segmental form at 8 different elevated temperatures, nominally at 30°C, 40°C, 50°C, 60°C, 70°C, 80°C, 90°C, and 100°C in the time interval of 3 hours, under loading in shear by a constant torque, Mt. The response of the material was measured in terms of rotational angle of the specimen, ^(t), as a function of time and then recalculated to the material creep compliance:

where r denotes radius of the circular cross section of the sample and l – length of the sample. t0 is the magnitude of constant shear stress loading, calculated as:

with polar momentum Ip for circular cross section geometry of cylindrical samples. The magnitudes of applied shear stress loading were sufficiently low to ensure that the entire measurement procedure remained within the scope of the theory of linear viscoelasticity.

Following the time-temperature superposition principle, measured segments were shifted along the time-scale in relation to the segment, measured at the nominal reference temperature, Tref = 50°C. Obtained shift factors were then modelled by WLF equation in order to obtain material constants, Ci and C2. By knowing these two constants we calculated shift factors that corresponded to the shifting of master curves in order to represent the creep behaviour at the reference temperature of 37°C.

RESULTS

STRERILIZATION EFFECT ON MATERIALS STRUCTURE

Regarding sterilization-related changes, no strong effect on both examined materials after applying different sterilization techniques was observed by means of optical microscopy. Sterilization processes with mentioned above conditions did not change the morphology neither for standard nor for modified PA6. However, discoloration effect took place. The color faded to a brownish hue from being exposed to each of three sterilization techniques.

STRERILIZATION EFFECT ON MATERIALS THERMAL PROPERTIES

The results of DSC measurements, i.e., melting temperature Tm, temperature of crystallization Tc, and enthalpies of corresponding transitions AHm and AHc, are presented in Tab. 1.

Tab. 1 DSC measurements characteristic data for two types of PA6

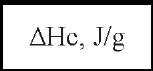

As before, first we dwell on non-sterilized monomodal and bimodal PA6 comparison first. It is evident that materials exhibit significantly different behavior during melting and crystallization. Fig. 3 shows non-isothermal melt-crystallization exotherms and subsequent melting endotherms for both materials. Clearly, a single crystallization peak was observed for each of them (Fig. 3a). However, monomodal PA6 exhibits gently sloping broad exothermal peak, while bimodal PA6 reveals sharp and lofty one. Such behavior corresponds to materials’ structure. Growth of big spherulites takes more time and heat is released bit by bit in this case, while small grains formation happens fast, and heat is released stepwise. Despite both peaks are situated in the same temperature range, crystallization temperatures, which are defined as peak temperatures, are different, being approximately 173.2°C for monomodal material and equal to 187.2°C for bimodal.

The second heating scan was used for melting peaks investigation. Such ones of mono- and bimodal PA6 are presented in the Fig. 3b. One may note that bimodal material melting peak is seemingly composed of two overlapped peaks with different peak temperatures: lower TmL and higher TmH. Double melting behavior was observed on overwhelming majority of first scans as well, especially for samples with low mass. In contrast with it, standard material exhibits a single melting peak. Most probably, such double-melting behavior corresponds to two different lamellar thicknesses that appear as a consequence of bimodal molecular mass distribution. Thus, the heating curve reflects the material nonuniform structure. Also it should be also noted that bimodal material indicates approximately 4% higher crystallinity than monomodal one.

Fig. 3 Crystallization exotherms (a) and subsequent melting endotherms (b) for monomodal and bimodal PA6 materials

To all appearance, the thermal properties of both materials were not significantly affected when samples were exposed to different sterilization methods. No additional transitions appearance due to sterilization was observed. Both materials exhibit the same crystallization and melting behaviour as in non-sterilized state.

NON-STERILIZED MONOMODAL AND BIMODAL MATERIALS COMPARISON

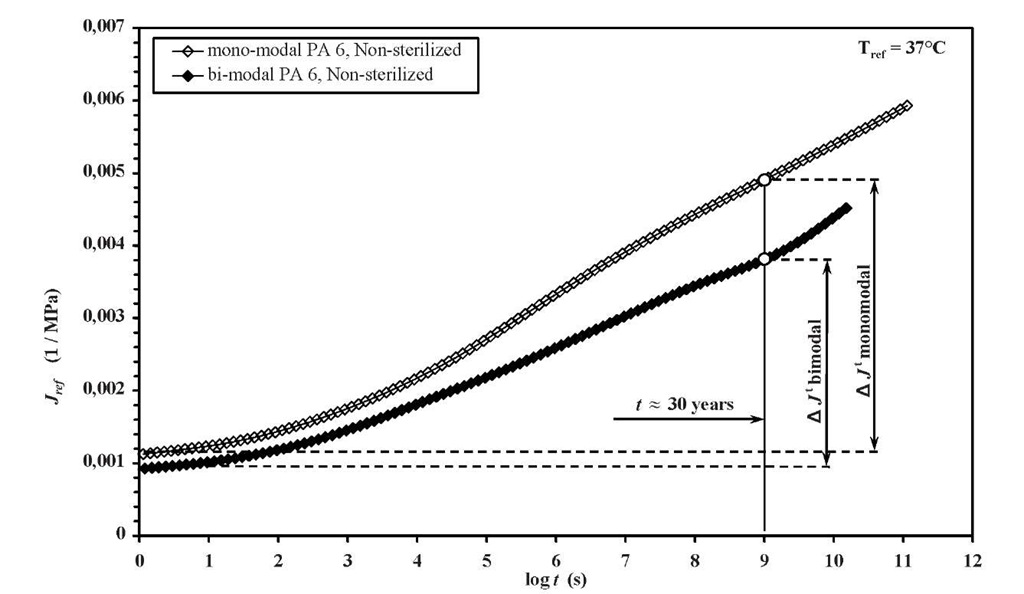

Performing creep tests according to the procedure described above we firstly investigated the difference in time -dependent mechanical behaviour of non-sterilized monomodal and bimodal PA6. In the concerned case it is appropriate to present the long-term creep behaviour at the reference temperature close to the temperature of a human body with respect to the proposed conditions of use. Fig. 4 shows comparison of time-dependent creep compliances for both non-sterilized PA6 materials for the reference temperature 37°C.

Fig. 4 Comparison of creep-compliances of non-sterilized monomodal PA6 and bimodal PA6 at reference temperature 37°C

Comparison of creep-compliances may be interpreted in terms of long-time stability for the products made of such materials. In the diagram it is clearly seen that creep compliance of both materials increase with time, but, nevertheless, creep compliance of bimodal material is lower than such of monomodal within all the time scale of experiment. From the point of view of desired life-span of dental implant it seems to be reasonable to analyse mechanical properties and their change in the time period of 30 years ~ 109s. In considered time period it can be observed that creep compliance of bimodal material is approximately 25% lower relative to the creep compliance of monomodal PA6 (Fig. 4) which indicates better creep resistance (long-term stability) properties of bimodal PA6. As it was observed from the optical microscopy pictures above (Fig. 1), bimodal PA6 has finer structure in comparison to monomodal PA6, which can consequently lead to better creep resistance properties of bimodal material. It is evident that both materials become less stiff with time, but for monomodal material this process is much faster than for bimodal one.

The absolute change in creep compliance, AJ’, which represents the magnitude of total deformation when the implant is exposed to constant load over certain period of time, for both materials may be estimated from the diagram as well. For monomodal material this change is bigger than for bimodal one. Thus, one may summarize that bimodal PA6 creeps much less in the same time period in comparison with monomodal PA6 both in absolute and relative numbers.

STERILIZATION INFLUENCE ON MATERIALS LONG-TERM MECHANICAL PROPERTIES

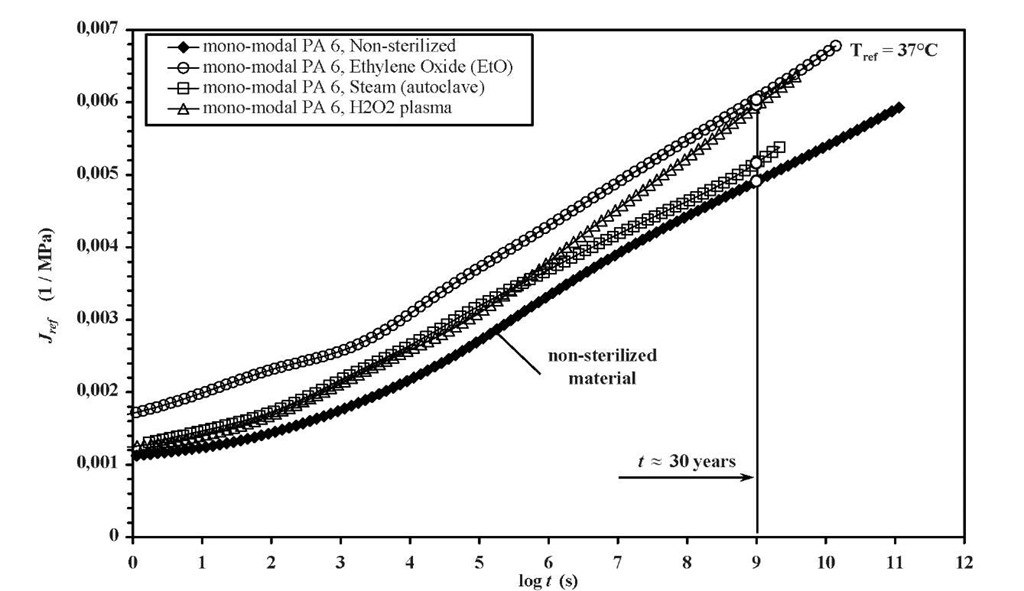

After exposure of both materials to three mentioned sterilization techniques it was investigated how much the process of sterilization affected their mechanical properties. Fig. 5 presents the comparison of creep compliances of non-sterilized and sterilized monomodal PA6 materials at reference temperature 37°C, whereas Fig. 6 shows the same comparison for bimodal PA6.

Fig. 5 Creep behaviour of non-sterilized and sterilized monomodal PA6 at reference temperature 37°C

From Fig. 5 one may observe all sterilization techniques have noticeable effect on long-term stability of monomodal material and all exhibit a tendency to deteriorate it at that. From the diagram it is clearly seen that EtO has the most severe effect on monomodal material time stability within whole time scale.

The diagram in Fig. 6 shows that in case of bimodal PA6 sterilization effect is not significant: the creep compliance curves of sterilized material stand much less apart from the one of non-sterilized than in case of monomodal material. At the same time it is also observed that EtO has the strongest effect on both materials.

Fig. 6 Creep behaviour of non-sterilized and sterilized bimodal I-PA6 at reference temperature 37°C

CONCLUSIONS

From performed analysis of both monomodal and bimodal PA6 materials properties in non-sterilized state and after exposure to three different sterilization techniques, the following conclusions can be made:

1) Non-sterilized bimodal material yields more complex structure (finer and more homogeneous) than non-sterilized standard PA6 material, when exposed to the same processing conditions during solidification ( Fig. 1)

2) No strong effect on the material structure was observed by means of optical microscopy after applying different sterilization methods to both materials. However, discoloration effect took place.

3) Non-sterilized monomodal and bimodal materials exhibit significantly different crystallization and melting behaviour (Fig. 3). Both materials show single crystallization peak. Subsequent melting endotherms showed single melting peak for monomodal material and double melting peak for bimodal. Such double melting behavior of bimodal PA6 is most probably caused by presence of two populations of lamellar thickness that sequent from bimodal molecular mass distribution. Crystallinity of bimodal material is approximately 4% higher than such for monomodal material.

4) Thermal properties of both materials were not affected when samples were exposed to different sterilization methods (Tab. 1). Both materials exhibit the same crystallization and melting behaviour as in non-sterilized state. No additional transitions were observed.

5) Characterization of time-dependent behaviour in terms of the creep compliance has shown that in non-sterilized state bimodal PA6 has better time stability than monomodal, since it creeps less (Fig. 4).

6) Applied sterilization techniques had more significant influence on the monomodal PA6 than on bimodal one (Fig. 5 and Fig. 6).

7) Within the whole investigated time scale the most significant effect on creep behaviour of monomodal PA6 as well as bimodal PA6 was observed after EtO sterilization.