ABSTRACT

Solvent migration in swelling polymer shows complex behaviour, as the interface of wet (rubbery) region moves along with solvent diffusion into the dry (glassy) region, which is accompanied by local deformation. This extrinsic mechanism has led to novel three-dimensional (3D) polymer micro-actuators using direct solvent delivery via microfluidic channels. Here we present experimental techniques to quantify the non-Fickian diffusion in the swelling polymer in an attempt to predict the dynamics of local deformation in such solvent driven micro-actuators. We recorded the evolving diffusion front of solvent in poly(ethylene glycol) diacrylate (PEG-DA) hydrogel upon wetting. In order to measure diffusivity of solvent in the polymer, magnetic resonance imaging (MRI) was used. Simulation result from the theory shows good agreement with Case II non-Fickian swelling experiment. We expect that our experimental methods for such coupled diffusion and deformation will help better capture the underlying physics of hydrogel behaviour and provide fundamental basis in exploration of various hydrogel applications.

INTRODUCTION

Hydrogel is a network of polymer chains which allows the diffusion of solvent in the network. Upon solvent diffusion, hydrogel undergoes significant volumetric change. This unique process has become increasingly important in many applications ranging from micro-actuators [1] to tissue engineering [2] to drug delivery [3]. Recently, we reported 3D hydrogel micro-actuators driven by capillary network [4, 5]. We embedded in the device microfluidic channels through which solvent is directly supplied to specific locations for swelling (Fig. 1). Therefore, complex 3D motion of the micro device was enabled by designing capillary network, unlike other hydrogel actuators where actuation relies mostly on simple expansion and shrinkage of the whole device. Since the actuation of our device is triggered by direct supply of solvent to dry polymer, study for solvent migration into glassy polymer and associated swelling deformation is important to understand and exploit this new class of micro actuation. It is well accepted that for most glassy polymers, at temperatures far above Tg (glass transition temperature), the diffusion follows Fick’s law, where the flux increases linearly with the gradient of solvent concentration. However, near or below Tg, more complicated non-Fickian behavior is observed. One particular instance of non-Fickian diffusion is called Case II diffusion. Because of the complex physical situation including moving interface between dry (glassy) and wet (rubbery) regions and strong coupling between solvent migration and polymer deformation, the coupled Case II diffusion and large deformation has not been fully explained by a mathematical model [6]. Here we present experimental techniques to characterize physical properties of hydrogel and to quantify the non-Fickian diffusion in the swelling polymer for better prediction of the dynamics of local deformation in solvent driven micro-actuators.

Fig. 1. Hydrogel actuator driven by embedded microfluidic channel for direct solvent delivery (a) Actuation of the device. Microfluidic channel is embedded off the center of the beam to the left side. When the tip of the channel touches solvent, solvent fills the channel via capillary force and subsequent local swelling around the channel makes the beam bend. (b) Schematic of polymer network in dry state and in swollen state

EXPERIMENTAL BACKGROUND

In our model for Case II diffusion coupled with a large deformation of polymer, the polymer network is modelled as a viscoelastic material characterized by Maxwell model [7] in the large deformation theoretical framework. Swelling of polymer by solvent sorption is modelled using free energy function by Flory [8], where Flory’s interaction parameter % represents enthalpic contribution from mixing solvent and polymer. Once elastic modulus is known, % can be calculated using the experimentally measured equilibrium swelling ratio ^eq. The diffusion kinetics states that the flux depends on the gradient of solvent concentration and the viscoleasticity of the polymer. In our study, a phenomenological relation is used to link the diffusion coefficient and the solvent concentration by following the Thomas-Windle model [9]. Self-diffusion coefficient of solvent molecules in polymer network is strongly dependent on solvent concentration in polymer. To quantify concentration dependent diffusion coefficient of water in PEG-DA hydrogel, we used magnetic resonance imaging (MRI) [10]. Coupling between mass transport of solvent and large deformation of polymer is described by molecular incompressibility and momentum balance equation. More detailed theoretical development of the model will be described elsewhere [11].

CHARACTERIZATION OF PHYSICAL PROPERTIES OF HYDROGEL

In this study, porous PEG-DA hydrogel was synthesized by mixing PEG-DA prepolymer with PEG in a weight ratio of 1:3 followed by addition of 2%wt. of photo-initiator for UV crosslinking. Not being polymerized, PEG contributes to reducing crosslinking density by occupying intermolecular space between PEG-DA during photo-polymerization, resulting in low modules and large swelling ratio. In addition, this polymer dramatically changes optical property from transparent to opaque as it swells. This facilitates visualization of the interface between dry and wet regions in experiment.

Swelling ratio of the hydrogel was measured in equilibrium state. Hydrogel disks were prepared and the diameter in dry state and fully swollen state in water was measured to obtain swelling ratio ^eq in length. ^eq =1.7, which corresponds to 400% volumetric increase upon swelling. Viscoelastic parameters of the hydrogel were obtained from compression test. We applied strain at constant rate and measured stress change over time. Parameters were extracted by fitting the data to Maxwell model (Table 1). Flory’s interaction parameter obtained using viscoelastic parameters and ^eq is % = 0.45. Hydrogel samples with different water concentration were prepared and diffusion coefficient of water in each sample was measured by MRI. Concentration dependent diffusivity obtained by curve-fitting to Thomas-Windle model is

where v is water volume fraction.

Table 1. Viscoelastic parameters

|

Er (MPa) |

Em (MPa) |

tm (s) |

n (x106 N-s/m2) |

V |

|

2.90 |

0.58 |

6.77 |

3.91 |

0.45 |

EXPERIMENT FOR COUPLED DIFFUSION AND SWELLING OF HYDROGEL

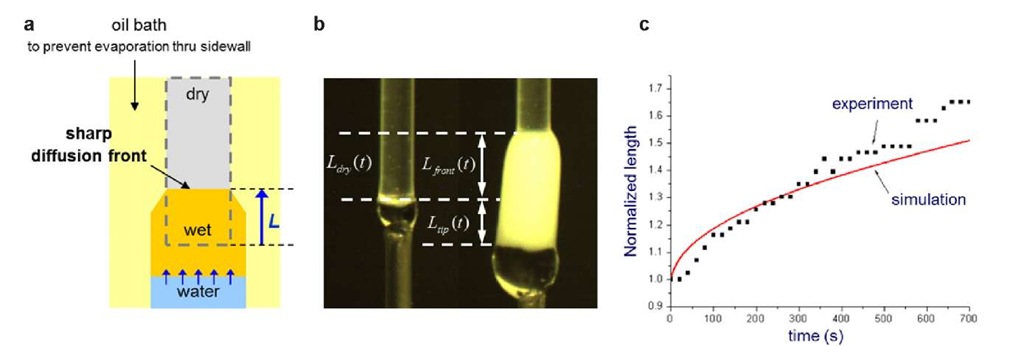

Non-Fickian diffusion and associated swelling of hydrogel was quantified by directly measuring diffusion front propagation and swelling length. In Case II diffusion, there is always a sharp boundary between dry and wet regions because diffusion is limited by slow mechanical relaxation of polymer. Since our porous PEG-DA hydrogel changes optical properties upon swelling, this sharp diffusion front can be clearly visualized and easily tracked while propagation. For one-dimensional (1D) diffusion experiment, a PEG-DA rod was prepared and made in contact with a water droplet on the tip (Fig. 2). Then, water starts to diffuse into the polymer network, creating a visible boundary indicating the location of diffusion front. This experiment was carried out in oil to prevent possible evaporation through the side wall of the rod, ensuring that solvent migration is primarily in the direction along the axis only. Diffusion front propagation was measured over time and compared to numerical simulation of the model using the parameters measured above. The result showed the presence of sharp diffusion front and its linear propagation trend, indicating Case II diffusion. In both diffusion front propagation and polymer deformation, simulation result agreed well with 1D swelling experiment of a PEG-DA rod. We expect that our theoretical model and experimental method for Case II diffusion will help better understand the underlying physics of hydrogel behaviour and provide fundamental basis in exploration of various hydrogel applications.

Fig. 2 (a) 1D Case II diffusion experiment configuration (b) PEG-DA rod in initial state (left) and during experiment (right) Diffusion front propagation is measured by tracking the sharp boundary. (c) Swelling-induced deformation of hydrogel from experiment and simulation