Vacuum processing is used in many industrial applications. Some of these processes and their typical working pressure ranges are shown in Figure V.2. The application of vacuum technology is especially critical to the success of the various coating processes.

Through the use of vacuum it is possible to create coatings with a high degree of uniform thickness ranging from several nanometers to more than 100 mm while still achieving very good reproducibility of the coating properties. Flat substrates, web and strip, as well as complex molded-plastic parts, can be coated with virtually no restrictions as to the substrate material.

The variety of coating materials is also very large. In addition to metal and alloy coatings, layers may be produced from various chemical compounds or layers of different materials applied in sandwich form. A significant advantage of vacuum coating over other methods is that many special coating properties desired, such as structure, hardness, electrical conductivity, or refractive index, are obtained merely by selecting a specific coating method and the process parameters for a certain coating material.

Deposition of thin films is used to change the surface properties of a base material or substrate. For example, optical properties such as transmission or reflection of lenses and other glass products can be adjusted by applying suitable coating layer systems. Metal coatings on plastic web produce conductive coatings for film capacitors. Polymer layers on metals enhance the corrosion resistance of the substrate.

Coating Sources

In all vacuum coating methods, layers are formed by deposition of material from the gas phase. The coating material may be formed by physical processes such as evaporation and sputtering, or by chemical reaction. Therefore, a distinction is made between physical vapor deposition (PVD) and chemical vapor deposition (CVD).

Thermal Evaporators

In the evaporation process, the material to be deposited is heated to a temperature high enough to reach a sufficiently high vapor pressure and the desired evaporation or condensation rate is set. The simplest sources used in evaporation consist of wire filaments, boats of sheet metal, or electrically conductive ceramics that are heated by passing an electrical current through them. However, there are restrictions regarding the type of material to be heated. In some cases, it is not possible to achieve the necessary evaporator temperatures without significantly evaporating the source holder and thus contaminating the coating. Furthermore, chemical reactions between the holder and the material to be evaporated can occur resulting in either a reduction of the lifetime of the evaporator or contamination of the coating.

Electron Beam Evaporators (Electron Guns)

To evaporate coating material using an electron beam gun, the material, which is kept in a water-cooled crucible, is bombarded by a focused electron beam and thereby heated. Since the crucible remains cold, in principle, contamination of the coating by crucible material is avoided and a high degree of coating purity is achieved. With the focused electron beam, very high temperatures of the material to be evaporated can be obtained and thus very high evaporation rates. Consequently, high-melting point compounds such as oxides can be evaporated in addition to metals and alloys. By changing the power of the electron beam, the evaporation rate is easily and rapidly controlled.

Cathode Sputtering

In the cathode sputtering process, the target, a solid, is bombarded with high energy ions in a gas discharge. The impinging ions transfer their momentum to the atoms in the target material, knocking the atoms off. These displaced atoms — the sputtered particles — condense on the substrate facing the target. Compared to evaporated particles, sputtered particles have considerably higher kinetic energy. Therefore, the conditions for condensation and layer growth are very different in the two processes. Sputtered layers usually have higher adhesive strength and a denser coating structure than evaporated ones.

Sputter cathodes are available in many different geometric shapes and sizes as well as electrical circuit configurations. What all sputter cathodes have in common is a large particle source area compared to evaporators, and the capability to coat large substrates with a high degree of uniformity. In this type of process, metals and alloys of any composition, as well as oxides, can be used as coating materials.

Chemical Vapor Deposition

In contrast to physical vapor deposition methods, where the substance to be deposited is either solid or liquid, in chemical vapor deposition, the substance is already in the vapor phase when admitted to the vacuum system. To deposit it, the substance must be thermally excited, i.e., by means of appropriate high temperatures or with plasma. Generally, in this type of process, a large number of chemical reactions take place, some of which are taken advantage of to control the desired composition and properties of the coating. For example, by using silicon-hydrogen monomers, soft silicon-hydrogen polymer coatings, hard silicon coatings, or — by the addition of oxygen — quartz coatings can be created by controlling process parameters.

Web Coating

Metal-coated plastic webs and papers play an important role in food packaging. Another important area of application of metal-coated web is the production of film capacitors for electrical and electronics applications.

Metal coating is carried out in vacuum web coating systems. The unit consists of two chambers, the winding chamber with the roll of web to be coated and the winding system, as well as the coating chamber, where the evaporators are located. The two chambers are sealed from each other, except for two slits through which the web runs. This makes it possible to pump high gas loads from the web roll using a relatively small pumping set. The pressure in the winding chamber may be more than a factor of 100 higher than the pressure simultaneously established in the coating chamber.

During the coating process, the web, at a speed of more than 10 m/s, passes a group of evaporators consisting of ceramic boats from which aluminum is evaporated. To achieve the necessary aluminum coating thickness at these high web speeds, very high evaporation rates are required. The evaporators must be run at temperatures in excess of 1400°C. Thermal radiation of the evaporators, together with the heat of condensation of the growing layer, yields a considerable thermal load for the web. With the help of cooled rollers, the foil is cooled during and after coating so that it is not damaged during coating and has cooled significantly prior to winding.

During the entire coating process, the coating thickness is continuously monitored with an optical measuring system or by means of electrical resistance measurement devices. The measured values are compared with the coating thickness set points in the system, and the evaporator power is thus automatically controlled.

Optical Coatings

Vacuum coatings have a broad range of applications in production of ophthalmic optics, lenses for cameras, and other optical instruments as well as a wide variety of optical filters and special mirrors. To obtain the desired transmission of reflection properties, at least 3, but sometimes up to 50, coatings are applied to the glass or plastic substrates. The coating properties, such as thickness and refractive index of the individual coatings, must be controlled very precisely and matched to each other.

Most of these coatings are produced using electron beam evaporators in single-chamber units. The evaporators are installed at the bottom of the chamber, usually with automatically operated crucibles, in which there are several different materials. The substrates are mounted on a rotating calotte above the evaporators. Application of suitable shielding, combined with relative movement between evaporators and substrates, results in a very high degree of coating uniformity. With the help of quartz coating thickness monitors and direct measurement of the attained optical properties of the coating system during coating, the coating process is fully controlled automatically.

One of the key requirements of coatings is that they retain their properties under usual ambient conditions over long periods of time. This requires the production of dense coatings, into which neither oxygen nor water can penetrate. Using glass lenses, this is achieved by keeping the substrates at temperatures up to 300°C during coating by means of radiation heaters. However, plastic lenses, as those used in eyeglass optics, are not allowed to be heated above 80°C.

To obtain dense, stable coatings these substrates are bombarded with argon ions from an ion source during coating. Through ion bombardment, the right amount of energy is applied to the growing layer so that the coated particles are arranged on the energetically most favorable lattice sites, without the substrate temperature reaching unacceptably high values. At the same time, oxygen can be added to the argon. The resulting oxygen ions are very reactive and ensure that the oxygen is included in the growing layer as desired.

Glass Coating

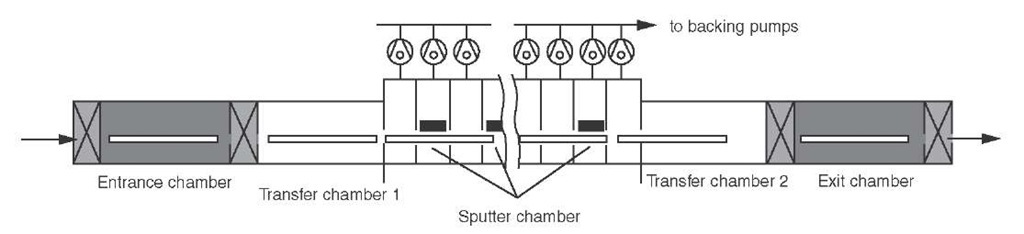

Coated glass plays a major role in a number of applications such as heat-reflecting coating systems on windowpanes to lower heating costs; solar protection coatings to reduce air-conditioning costs in countries with high-intensity solar radiation; coated car windows to reduce the heating-up of the interior; and mirrors used both in the furniture and the automobile industry. Most of these coatings are produced in large in-line vacuum systems such as that shown in Figure V.3.

The individual glass panes are transported into an entrance chamber at atmospheric pressure. After the entrance valve is closed, the chamber is evacuated with a fore pump set. As soon as the pressure is low enough, the valve to the evacuated transfer chamber can be opened. The glass pane is moved into the transfer chamber and from there at constant speed to the process chambers, where coating is carried out by means of sputter cathodes. On the exit side, there is, in analogy to the entrance side, a transfer chamber in which the pane is held until it can be transferred out through the exit chamber.

FIGURE V.3 Plant for coating glass panes — three-chamber in-line system with throughput up to 3,600,000 m2/year.

Most of the coatings consist of a stack of alternative layers of metal and oxide. Because the metal layers may not be contaminated with oxygen, the individual process stations have to be vacuum-isolated from each other and from the transfer stations. To avoid frequent and undesirable starting and stopping of the glass panes, the process chambers are vacuum-separated through so-called "slit locks," i.e., constantly open slits combined with an intermediate chamber with its own vacuum pump. The gaps in the slits are kept as small as technically possible to minimize clearance and therefore conductance as the glass panes are transported through them. The pumping speed at the intermediate chamber is kept as high as possible to achieve a considerably lower pressure in the intermediate chamber than in the process chambers. This lower pressure greatly reduces the gas flow from a process chamber via the intermediate chamber to the adjacent process chamber. For very stringent separation requirements, it may be necessary to place several intermediate chambers between two process chambers.

The glass coating process requires high gas flows for the sputter processes as well as low hydrocarbon concentration. Turbomolecular pumps are used almost exclusively because of their high pumping speed stability over time.

While the transfer and process chambers are constantly evacuated, the entrance and exit chambers must be periodically vented and then evacuated again. Because of the large volumes of these chambers and the short cycle times, a combination of rotary vane pumps and Roots pumps is typically used to provide the necessary pumping speed.

Data Storage Disks

Coatings for magnetic- or magneto-optic data storage media usually consist of several functional coatings that are applied to mechanically finished disks. Most disks must be coated on both sides, and there are substantially greater low particle contamination requirements as compared to glass coating. The sputter cathodes in the process stations are mounted on both sides of the carrier so that the front and back of the disk can be coated simultaneously.

An entirely different concept is applied for coating of single disks. In this case, the different process stations are arranged in a circle in a vacuum chamber. The disks are transferred individually from a magazine to a star-shaped transport arm. The transport arm cycles one station farther after each process step and in this way transports to substrates from one process station to the next.

During cycling, all processes are switched off and the stations are vacuum-linked to each other. As soon as the arm has reached the process position, the individual stations are separated from each other by closing seals. Each station is pumped by means of its own turbomolecular pump and the individual processes are started. By sealing off the process stations, excellent vacuum separation of the individual processes can be achieved. However, since the slowest process step determines the cycle interval, two process stations may have to be dedicated for particularly time-consuming processes.