Introduction

As a shotgun fires cartridges loaded with pellets, the charge emerges from the muzzle en masse and travels as such for about a couple of meters; then, the pellets begin to disperse, decreasing the number of pellets actually striking the target. The dispersion of the shot is clearly a function of distance, and the recognition of this relationship permits the determination of the distance between the firearm and the target at the instant of discharge. This estimation of the firing range, usually expressed from the muzzle end of the gun barrel to the target, is an essential element of the investigation. Generally, the distribution of pellets on a target allows for determination of the range of fire up to 20 or 30 m with considerable accuracy. At these distances, the shotgun pattern has no other characteristics (such as tattooing, blackening, burning, presence of a gunshot residues pattern, etc.) that could also be used for the determination of shooting distance. At closer ranges, the firing distance evaluation by shot dispersion can be complemented by analysis of the gunshot residues pattern (by optical methods and by means of specific chemical tests) and/or by exploiting others of the characteristics mentioned above.

The degree of dispersion of the shot depends on many factors, the most important of which are the type of pellets, the cartridge pressure, the wadding, the barrel length and the extent of choke. A complete analytical solution to the exact pellet dynamics is a very complicated problem, including dynamic forces, constraints and boundary conditions not completely known.

The Shot Shell

In order to fully understand various aspects of the degree of pellet spread, it is important to explain the different components of a shot shell. A shot shell consists of a cylindrical casing containing the powder (mostly smokeless), the charge (pellets or slug) and one or more wads; buffer material is sometimes present. The mouth of the cartridge is closed either by a crimp closure or an overshot wad.

The pellets (or shot)

Currently, four types of shot are available on the market: drop or soft shot (essentially pure lead), chilled or hard shot (hardened by the addition of antimony), steel shot and plated shot. Individual steel pellets weigh less than comparably sized lead pellets and thus have less range; plated shot is lead shot coated with a thin coat of copper and/or nickel to minimize distortion on firing, thus maintaining a good aerodynamic shape and increasing the range. Other softer, nonlead materials (e.g. tungsten in an organic polymer, bismuth/tin alloys, molybdenum, zinc alloys, etc.) have been tried or used recently in an attempt to increase the ballistic performance of the shot. If patterns caused by the different types of shot are examined, it appears that the harder shot gives a more uniform distribution of pellets.

Buckshot pellet patterns may be influenced at short distances by the stacking order of the pellets in the cartridge case, appearing as a series of superimposed triangles on the pattern (Fig. 1).

The velocity of the shot at the muzzle of the firearm is a parameter influencing the distribution of the pellets. The velocity of the shot is itself determined by the burning of the propellant powder and the length of the barrel. For traditional shot shells, the higher the pressure generated by the cartridge, the more the shot will be disrupted as it emerges from the barrel by the following gases. While this effect is largely offset by the wads used in modern cartridges, it is a factor that does affect the dispersion of shot.

Apart from the ammunition for shotguns with smooth barrels, special rounds with shot charge exist for handguns and rifles, more particularly in calibers .22 LR, .38 Special, .44 Magnum, .45 ACP and 9 mm Luger. Flobertcartridges loaded with shotare also available.

Figure 1 Cross-section of a shot shell containing buckshot pellets.

The wadding

The wadding in traditional shotgun cartridges consists of an over powder wad, a series of filler wads and an overshot wad. This construction suffers from a number of drawbacks, which can lead to distorted and enlarged patterns on the target. In fact, on firing, some hot gases from burning powder are able to bypass the over powder and filler wads to reach the shot charge; these gases partially melt and fuse together a number of pellets. Likewise, the filler wads do not provide sufficient cushioning of the shot to prevent distortion due to intershot contact; in extreme cases, the rapid acceleration of the shot charge causes pellets at the bottom of the charge to be ‘welded’ together by the pressure into small clumps. Apart from this effect, the filler wad can fly into the rear part of the shot and scatter it.

Furthermore, during the passage of the shot through the barrel, pellets in contact with the inside surface of the bore are distorted or abraded as a result of both pressure and friction. Deformed or abraded pellets are aerodynamically less stable because they will suffer greater effects from air resistance. Consequently, they will not retain as much speed and energy, resulting in a trajectory deviating from the flight path of the main body of shot. These so-called ‘fliers’ are present in all shotgun patterns and can also be due to irregularly shaped shot, or pellets that become imbedded in the wads, etc. Long-shot columns aggravate the conditions described, thus leading to increased pellet deformation and hence a greater occurrence of fliers.

Another impairment to a good pattern is the overshot wad; this is supposed to slide off to one side of the shot column as it emerges from the barrel. This does notalways happen, and the overshotwad sometimes remains in the shot column, disrupting it and causing a cartwheel pattern. If the overshot wad is found on the target, it is an indication of a close shot.

Modern wads tend to be of the plastic cup type with an integral shock absorber and gas seal (Fig. 2). The shock absorber consists of a semi collapsible section that very effectively cushions the shot column at the moment of acceleration. The integral plastic cup protects the shot during its passage through the bore and the plastic gas seal prevents the leakage of hot gases into the shot column. Cartridges loaded with this type of one piece wad (monowad) will give a much more controlled spread of shot than one loaded with the old type of wad column. The walls of the cup are split so that after exiting the air pressure divides the walls into sections, resulting in more air resistance while not disturbing the trajectory of the shot. Crimping or folding of the casing material eliminates the necessity of having an overshot wad.

Figure 2 Different designs of plastic cup wads.

Shotgun wadding trajectories When a shotgun is fired, the trajectory of the different compounds of a wadding depends on its weight and shape. The wadding can be projected to 30 m or further and it can deviate from the center of the flight path of the shot. The lighter weight for a less aerodynamic shape enhances the air resistance, so that the total length of the trajectory is considerably reduced. As the wadding strike effects can sometimes be extremely reproducible, they allow the forensic scientist to conduct firing tests to determine the range of firing.

Apart from the shooting distance determination, the examination of the wad will give an indication of the caliber of the shotgun and the make of the ammunition.

The buffer material (or granulated filler)

The buffer material, mostly made of polyethylene or polypropylene and found primarily in larger birdshot and in buckshotloads, cushions the shotpellets on firing, reducing shot distortion and improving the shot pattern. The filler accompanies the shot toward the target and can produce stipple marks on the skin identical in appearance to powder tattoo marks. Marks from the filler can vary from large and irregular, to small and regular, depending on the size and shape of the granules. Buffer material can be consistently deposited on targets up to 4.5-6 m from the muzzle, and along the ground the distribution of buffer may be seen up to about 9 m. The distribution diameter of buffer also shows a linear expansion as a function of range of fire. The rate of expansion is, however, far in excess of the pellet distribution diameter, resulting in a near constant buffer distribution diameter beyond about 3 m. Crosswind can produce significant distortion in the buffer distribution, and therefore range of fire estimations based on this parameter should be approached cautiously.

The Barrel

Shortening the barrel by sawing off the end of the muzzle does have some effect on the spread of shot. What effect exists, however, is mainly due to the high-pressure gases disrupting the shot column as it exits from the barrel. Shotgun propellants are very fast burning, giving rise to a very sharp increment in pressure during the first few moments of ignition. In full-length barrels the overall pressure within the barrel drops very considerably as the shot nears the muzzle, and the volume of gas between the over-powder wad and the breech of the weapon increases. As the barrel is progressively shortened, the pressures being exerted on the base of the shot column as it exits the barrel become progressively greater. These pressures can lead to a destabilization of the shot column, resulting in a ‘blown’ pattern; this effect, which increases with each shortening of the barrel, can be identified by an irregular shot pattern and a larger spread than would normally be expected. For some brands of cartridges this increase in spread of the pattern is important; for other brands of ammunition, the spread remains constant.

Another effect of shortening the barrel is to remove the effect of the ‘choke’.

The choke

Most shotgun barrels have a constriction applied to the muzzle end of the weapon’s bore so as to control the spread of the shot. This constriction is called ‘choke’ and may start anywhere from 2.5 cm (l”)to 15.2 cm (6″) from the end of the barrel. The choke constricts the diameter of the shot column, increasing its overall length as well as the velocity of the pellets at the front of the shot charge. The cone-shaped reduction in the barrel results in the outer layers of shot in the column being given an inward acceleration, which delays the spreading of the shot once it leaves the barrel and reduces its tendency to separate in flight. A certain number of pellets suffer some deformation in the process, both from friction with the barrel walls and by their interaction with each other.

Some barrels intended for use at close ranges are bored without choke and are referred to as being bored ‘true cylinder’; the lightest choke in the English system is referred to as ‘improved cylinder’ (0.12 mm), followed by ‘quarter choke’ (0.25 mm), ‘half choke’ (0.50 mm), ‘three-quarter choke’ (0.75 mm) and, finally, ‘full choke’ (1 mm). Itshould be noted that American and Continental choke designations are slightly different. Different degrees of choke will give different patterns for a particular shotgun charge; the tighter the degree of choke, the smaller the pattern of shot at the target. At the same range and assuming the same barrel length, cartridge type and pellet size, all bores with a given choke having different calibers (with the exception of the .410) produce approximately the same size patterns. Obviously, the patterns will differ in density.

The degree of choke is based upon the percentage of pellets that will stay inside a 76.2 cm (30″) circle at 36.6 m (40 yards), with exception to the .410 shotgun, in which the pattern of shot is determined in a 50.6 cm (20″) circle at22.9m (25 yards). Table 1 gives the percentage of shot that can be expected for the various choke borings. There are slight variations, which depend upon the size of shot used; if cartridges of different shot size are loaded to the same average velocity the large shot will show a better result. It should be stressed that the percentages of Table 1 may be higher when using modern ammunition because of improvements in shot shell design. This improvement in pattern performance is true for all chokes and itdecreases with smaller shotsizes.

In addition to the barrel choke and barrel length, the condition of the bore (either smooth or rifled, corroded, damaged, etc.), the length of chamber cone and the size of the chamber will affect the pattern. For example, if the bore of a gun has become pitted due to corrosion it will increase the friction of the shot.

Shooting Range Estimation

At ranges of within 1 m, the pellets are still travelling as a compact mass, thus the entrance hole will be a single perforation of large size (approximately 23 cm). Contrary to intuition, it is frequently not possible to determine accurately either bore or shot size. As the range increases, the edges of the impact will have scalloped margins. Still farther away, the pellets start to disperse, leaving scattered satellite pellets holes around the central impact. The separation and the number of these pellets will increase further with increasing distance. At distances of about 3 m, buckshot pellets cause isolated impacts.

The question of correlating range with pellet dispersion is usually approached with the assumption that the entire distribution of pellets is available for examination. In practice, the target usually reflects only a portion of the pattern and thus the range estimation is seriously limited by the size of the target. Due to the relatively small size of the average human target, this applies more particularly to victims. In this case, it is impossible to estimate the range from a measurement of the whole pattern diameter; the only measurements available are the distances between a limited number of pellet holes, and the estimation of shooting distance is scarcely reliable. Partial pellet patterns sometimes allow the examiner to position the victim within the void characterizing the pellet pattern present on the crime scene.

Table 1 Percentage of shot at 36.6 m in a 76.2 cm diameter circle, according to the different chokes

| Boring of gun | Percentage of shot |

| True cylinder | 40 |

| Improved cylinder | 50 |

| // choke | 55 |

| Vfe choke | 60 |

| 3/4 choke | 65 |

| Full choke | 70 |

Where more than one shot has been fired, one should be very reticent in making any positive range determination. Another important aspect is the way the target was exposed to the charge of shot at the time of shooting. In fact, when the pellets strike the surface by an angle of incidence other than 90°,the density will appear less.

Considerable effort has been devoted to the development of empirical and mathematical models to describe the dispersion of shot from the discharge of a shotgun; many formulas have been published, but several workers have questioned their applicability. The only reliable method of determining range is to obtain the suspect weapon and a sufficient quantity of rounds of the same brand of ammunition believed to have fired the questioned pattern and then conduct a series of test shots so as to reproduce the pattern of the shooting incident. The best test ammunition is that belonging to the same batch as the cartridge of the crime. The pellet patterns can be recorded on butcher paper targets at different distances from the muzzle (Fig. 3). If buckshot shot shells are used, the patterns at different distances can be recorded at the same time by using an in-line array of several thin paper targets placed at known intervals from the muzzle of the shotgun. Although such an approach seems rather unsophisticated, it is capable of a remarkable degree of accuracy.

The generalizations available in the literature provide only a very rough estimate, as the variations of the type of powder, type of load, length of the barrel, degree of choke, etc. are too great. For example, some researchers have shown that two lots of ammunition manufactured within days of one another show similar ballistic performances, while those manufactured months apart have very different ballistic performances. The conditions in which shot shells have been stored may seriously compromise the determination of distance; shot shells that have been stored in cold weather may produce pellet patterns on a much more restricted range than those stored under more ‘normal’ conditions. In fact, the reduced temperature produces a slowing down of the burning process of the gunpowder, which reduces the pressure in the barrel chamber and lowers the velocity of the shot. Consequently, there is less natural deformation of the pellets, which results in less air resistance and smaller dispersion of the pellets, at least at close distances.

Should there not be enough rounds available, a useful range of fire estimation can be obtained by firing a differentbrand of ammunition. A scaling factor allows one to transform the results, based on a comparison of the patterns obtained with the two different ammunitions at the same distance.

Figure 3 Shot dispersion recorded on paper sheets at various muzzle-to-target distances: (A) 2.5m; (B) 5 m; (C) 7.5 m; and (D) 10 m. A 12/70 Mossberg 500A true cylinder riot gun was used to fire Sellier and Bellot shot shells containing 32 g steel shot with a diameter of 3.5 mm.

The test shots on paper provide a permanent record of the effects of blackening, tattooing, burning, powdering, buffer and wadding impact marks as well as pellet spread. One has to take into account that no shotgun/shot shell combination will fire exactly the same size pattern at a given distance repeatedly, and also that some guns and loadings will pattern more uniformly and with greater regularity than others. It is therefore advisable to illustrate the variation in pattern size at a given range by carrying out a sensible number of test firings. In practice, it is suggested that atleast three shots should be fired a teach test distance; of course, the more shots fired at a given distance, the more accurate the findings will be.

Generally, as the distance from the muzzle to target increases, so does the amount of variation in pattern size. The larger the variation between shots, the larger the range of distances at which the shot could have been fired is going to be.

The spread of the pellet pattern can be characterized by using several parameters, based on the measurement of a characteristic length or number. The mostcommon among them are:

1. The area or the square root of the area of the smallest rectangle that encloses the entire pellet pattern.

2. The greatest average diameter (or greatest diameter method), which is the measure of the distance between the outermost pellets in the pattern and enables the determination of the average diameter of the pattern.

3. The radius of the smallest circle enclosing the total pattern.

4. The equivalent circle diameter (ECD), which corresponds to the circumference of the polygon formed by the outermost pelletholes divided by 77.

5. The distances between pellets within the pattern.

6. The effective shot dispersion (ESD)={(4/No)£Ri2}/2 where No is the total number of pellets and Ri is the radial distance of the i-th pellet from the center of the pattern.

7. The percentage of shots being dispersed outside a circle of a certain diameter about the pattern center.

In all these measurements, flier pellets have to be discarded; it is not uncommon for fliers to increase the actual pattern diameter to twice that of the bulk of the shot charge

The number of pellets to be accounted for will influence the choice of a particular technique. In this article, we will shortly digress on techniques (4) and (7), as we feel they are well suited for buckshot and birdshot, respectively.

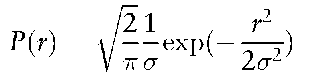

For a large number of pellets, their distribution around the center should be rotationally symmetric, while the radial component r reflects a gaussian distribution. Recent experiments have cast doubt on its gaussian character for the central region of the distribution. Given a large number of pellets and that we are merely interested in the outward region, the probability of finding a pellet at a distance r to the center is given by:

The proportion of pellets falling within a circle with radius r is given by the integration from 0 to r. In this formula, a is the width (mean deviation) of the distribution. The factor v^/t ensures that the distribution is properly normalized when integrating of all radii 0 < r <oo. Hence, all the pellets can be expected to be found only within a circle having an infinite diameter. For a circle with a given radius, the incidentproportion of pellets is given in Table 2. This table provides a means of determining by measuring the radius of the circle containing 95 or 97% of the pellets.

A statistical analysis of the results obtained by the greatest diameter method (2), as well as from the ECD method (4), shows that the ECD method gives the most reliable results. Confidence limits can be obtained by performing a statistical analysis on several test firings or by simply taking the upper and the lower limit of a limited set of values. In the latter case, the obtained confidence will depend on the number of test firings. The results can be plotted on a graph (width versus range of fire), together with the confidence levels. The pattern found on the crime scene can be converted to a range of fire with a corresponding confidence limit(maximum and minimum likely ranges of firing) using this graph or after performing a linear regression analysis. This graphical solution accounts for the lack of confidence limits available for the pattern present on the crime scene.

Intermediate targets

Shot charges may strike an intermediate target such as a pane of glass, a screen or an arm before impacting the final target. This intermediate target will increase the dispersion of the shot and a disproportionately wide spread is observed as long as the majority of pellets hit the target en masse. An explanation for this phenomenon may be that pellets, particularly at close ranges, are deflected by striking each other during their passage through the intermediate target, with the resulting effects possibly enhanced by the initially higher velocity. Contact or close-range wounds may create a similar effect inside the body. In cases where the pellets pass through an intermediate target, the only way to determine the range correctly is to interpose a similar target when firing. In some cases, no reliable firing range determination can be made. Heavy clothing can act as an intermediate target, enlarging the pellet pattern present on the body of the victim. For decomposed or burned bodies, it may seem convenient to obtain the pellet pattern using X-rays but experiments have shown that this method is completely unreliable.

Table 2 Percentage of pellets within a circle with a given radius around the center of impact

| Radius | Percentage of |

| pellets | |

| a | 68 |

| 1.64a | 90 |

| 2a | 95 |

| 2.17a | 97 |

Intermediate targets may also reduce the number of pellets in the pattern by ricocheting or stopping the pellets, as, for example, occurs when trees are in the line of fire.

Adaptations

Certain adaptations, to both gun and cartridge, can be employed to increase the shot spread. Special slow twist rifled barrels are made for such purposes; special shot spacers can be used in the cartridge loading; some devices, called shotgun diverters, can also be attached to the muzzle end of a shotgun in order to change the normal circular pattern of shot to a controlled, predictable, rectangular or ellipsoidal pattern, the notion being that the increase in lateral spread will give a higher probability of hits.

Some Misconceptions

One common misconception is that the distance, in inches, from the center of the pattern to the point where the wads hit the target gives the range in yards. This is totally untrue and should never be used for estimation of range of firing. Another misconception is that in heavy rain the pellets will be disrupted by the raindrops.