LITHIUM NIOBATE MODULATORS

The most direct way to create a modulated optical signal for communications applications is to directly modulate the current driving the laser diode. However, as discussed in the sections on lasers, this may cause turn-on delay, relaxation oscillation, mode-hopping, and/or chirping of the optical wavelength. Therefore, an alternative often used is to operate the laser in a continuous manner and to place a modulator after the laser. This modulator turns the laser light on and off without impacting the laser itself. The modulator can be butt-coupled directly to the laser, located in the laser chip package and optically coupled by a microlens, or remotely attached by means of a fiber pigtail between the laser and modulator.

Lithium niobate modulators have become one of the main technologies used for highspeed modulation of continuous-wave (CW) diode lasers, particularly in applications (such as cable television) where extremely linear modulation is required, or where chirp is to be avoided at all costs. These modulators operate by the electro-optic effect, in which the applied electric field changes the refractive index. Integrated optic waveguide modulators are fabricated by diffusion into a lithium niobate substrate. The end faces are polished and butt-coupled (or lens-coupled) to a single-mode fiber pigtail (or to the laser driver itself). This section describes the electro-optic effect in lithium niobate, its use as a phase modulator and an intensity modulator, considerations for high-speed operation, and the difficulties in achieving polarization independence.40

The most commonly used modulator is the Y-branch interferometric modulator shown in Fig. 26, discussed in a following subsection. The waveguides that are used for these modulators are fabricated in lithium niobate either by diffusing titanium into the substrate from a metallic titanium strip or by using ion exchange. The waveguide pattern is obtained by photolithography. The standard thermal indiffusion process takes place in air at 1050°C over 10 h. An 8-^m-wide strip of titanium 50 nm thick creates a fiber-compatible single mode at 1.3 |im. The process introduces -1.5 percent titanium at the surface, with a diffusion profile depth of -4 |im. The result is a waveguide with increased extraordinary refractive index of 0.009 at the surface. The ordinary refractive index change is -0.006. A typical modulator will use aluminum electrodes 2 cm long, etched on either side of the waveguides, with a gap of 10 |im.

In the case of ion exchange, the lithium niobate sample is immersed in a melt containing a large proton concentration (typically benzoic acid or pyrophosphoric acid at >170°C), with some areas protected from diffusion by masking; the lithium near the surface of the substrate is replaced by protons, which increases the refractive index. The ion-exchange process changes only the extraordinary polarization; that is, only light polarized parallel to the Z axis is wave guided.

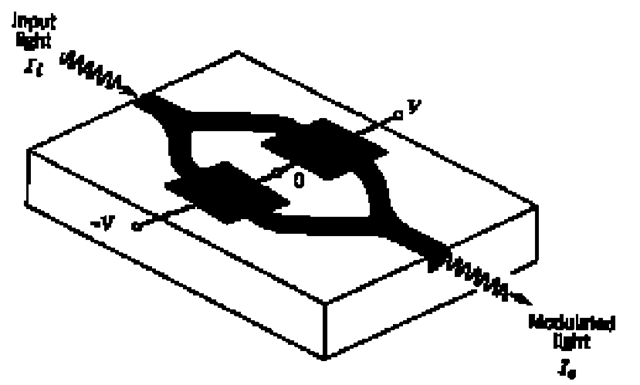

FIGURE 26 Y-branch interferometric modulator in the "push-pull" configuration. Center electrodes are grounded. Light is modulated by applying positive or negative voltage to the outer electrodes.

Thus, it is possible in lithium niobate to construct a polarization-independent modulator with titanium indiffusion, but not with proton-exchange. Nonetheless, ion exchange makes possible a much larger refractive index change (~0.12), which provides more flexibility in modulator design. Annealing after diffusion can reduce insertion loss and restore the electro-optic effect. Interferometric modulators with moderate index changes (An < 0.02) are insensitive to aging at temperatures of 95°C or below. Using higher index change devices, or higher temperatures, may lead to some degradation with time. Tapered waveguides can be fabricated easily by ion exchange for high coupling efficiency.41

Electro-Optic Effect

The electro-optic effect is the change in refractive index that occurs in a noncentrosymmetric crystal in the presence of an applied electric field. The linear electro-optic effect is represented by a third-rank tensor. However, using symmetry rules it is sufficient to define a reduced tensor rit, where i = 1 … 6 and j = x, y, z, denoted as 1, 2, 3. Then, the linear electro-optic effect is traditionally expressed as a linear change in the inverse refractive index squared.

where Ej is the component of the applied electric field in the jth direction. The applied electric field changes the index ellipsoid of the anisotropic crystal into a new form based on Eq. (76):

where the diagonal elements are given by:

and the cross terms are given by

The presence of cross terms indicates that the ellipsoid is rotated and the lengths of the principal dielectric axes have changed.

Diagonalizing the ellipsoid of Eq. (77) will give the new axes and values. The general case is treated in Vol. II, Chap. 13. In lithium niobate, the material of choice for electro-optic modulators, the equations are simplified because the only nonzero components and their magnitudes are42:

The crystal orientation is usually chosen so as to obtain the largest electro-optic effect. This means that if the applied electric field is along Z, then light polarized along Z sees the largest field-induced change in refractive index. Since![]() performing the difference gives

performing the difference gives ![tmp8-620_thumb[2][2][2][2][2][2]_thumb tmp8-620_thumb[2][2][2][2][2][2]_thumb](http://what-when-how.com/wp-content/uploads/2011/09/tmp8620_thumb222222_thumb_thumb.png)

We have included a filling factor r (also called an optical-electrical field overlap parameter) to include the fact that the applied field may not be uniform as it overlaps the waveguide, resulting in an effective field that is somewhat less than 100 percent of the maximum field.

In the general case for the applied electric field along Z, the only terms in the index ellipsoid will be![]() This means that the index ellipsoid has not rotated, its axes have merely changed in length. Light polarized along any of these axes will see a pure phase modulation. Because r33 is largest, polarizing the light along Z and providing the applied field along Z will provide the largest phase modulation. Light polarized along either X or Y will have the same (although smaller) index change, which might be a better direction if polarization-independent modulation is desired. However, this would require that light enter along Z, which is the direction in which the field is applied, so it is not practical.

This means that the index ellipsoid has not rotated, its axes have merely changed in length. Light polarized along any of these axes will see a pure phase modulation. Because r33 is largest, polarizing the light along Z and providing the applied field along Z will provide the largest phase modulation. Light polarized along either X or Y will have the same (although smaller) index change, which might be a better direction if polarization-independent modulation is desired. However, this would require that light enter along Z, which is the direction in which the field is applied, so it is not practical.

As another example, consider the applied electric field along Y. In this case the nonzero terms are

It can be seen that now there is a YZ cross-term, coming from r42. Diagonalization of the perturbed index ellipsoid finds new principal axes, only slightly rotated about the Z axis. Therefore, the principal refractive index changes are essentially along the X and Y axes, with the same values as A(1/n2)1 and A(1/n2)2 in Eq. (79). If light enters along the Z axis without a field applied, both polarizations (X and Y) see an ordinary refractive index. With a field applied, both polarizations experience the same phase change (but opposite sign). We later describe an interferometric modulator that does not depend on the sign of the phase change. This modulator is polarization independent, using this crystal and applied-field orientation, at the expense of operating at somewhat higher voltages, because r22 < r33.

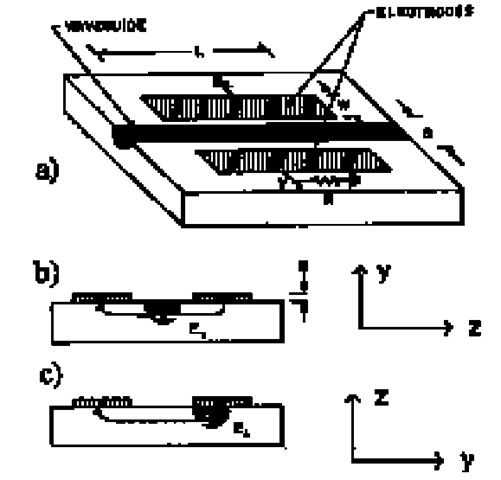

Since lithium niobate is an insulator, the direction of the applied field in the material depends on how the electrodes are applied. Fig. 27 shows a simple phase modulator. Electrodes that straddle the modulator provide an in-plane field as the field lines intersect the waveguide, as shown in Fig. 27b.

FIGURE 27 (a) Geometry for phase modulation in lithium niobate with electrodes straddling the channel waveguide. (b) End view of (a), showing how the field in the channel is parallel to the surface. (c) End view of a geometry placing one electrode over the channel, showing how the field in the channel is essentially normal to the surface.

This requires the modulator to be Y-cut LiNbO3 (the Y axis is normal to the wafer plane), with the field lines along the Z direction; X-cut LiNbO3 will perform similarly. Figure 27c shows a modulator in Z-cut LiNbO3. In this case, the electrode is placed over the waveguide, with the electric field extending downward through the waveguide (along the Z direction). The field lines will come up at a second, more distant electrode. In either case, the field may be fringing and nonuniform, which is why the filling factor r has been introduced.

Phase Modulation

Phase modulation is achieved by applying a field to one of the geometries shown in Figure 27. The field is roughly V/G, where G is the gap between the two electrodes. For an electrode length L, the phase shift is:

The refractive index for bulk LiNbO3 is given by43:

Inserting numbers for a wavelength of![]() When

When![]() phase shift is expected in a length L – 1 cm.

phase shift is expected in a length L – 1 cm.

It can be seen from Eq. (80) that the electro-optic phase shift depends on the product of the length and voltage. Longer modulators can use smaller voltages to achieve n phase shift. Shorter modulators require higher voltages. Thus, phase modulators typically use the product of the voltage required to reach n times the length as the figure of merit. The modulator just discussed has a 5 V cm figure of merit.

The electro-optic phase shift has a few direct uses, such as providing a frequency shifter (since 9^/9t ^ v). However, in communication systems this phase shift is generally used in an interferometric configuration to provide intensity modulation, discussed next.

Branch Interferometric (Mach-Zehnder) Modulator

The interferometric modulator is shown schematically in Fig. 26. This geometry allows wave-guided light from the two branches to interfere, forming the basis of an intensity modulator. The amount of interference is tunable by providing a relative phase shift on one arm with respect to the other. Light entering a single-mode waveguide is equally divided into the two branches at the Y junction, initially with zero relative phase difference. The guided light then enters the two arms of the waveguide interferometer, which are sufficiently separated that there is no coupling between them. If no voltage is applied to the electrodes, and the arms are exactly the same length, the two guided beams arrive at the second Y junction in phase and enter the output single-mode waveguide in phase. Except for small radiation losses, the output is equal in intensity to the input. However, if a n phase difference is introduced between the two beams via the electro-optic effect, the combined beam has a lateral amplitude profile of odd spatial symmetry. This is a second-order mode and is not supported in a single-mode waveguide. The light is thus forced to radiate into the substrate and is lost. In this way, the device operates as an electrically driven optical intensity on-off modulator. Assuming perfectly equal splitting and combining, the fraction of light transmitted is:

where![]() is the difference in phase experienced by the light in the different arms of the interferometer:

is the difference in phase experienced by the light in the different arms of the interferometer:![]() is the difference in refractive index between the two arms, and L is the path length of the refractive index difference. The voltage at which the transmission goes to zero

is the difference in refractive index between the two arms, and L is the path length of the refractive index difference. The voltage at which the transmission goes to zero![]() is usually called Vn. By operating in a push-pull manner, with the index change increasing in one arm and decreasing in the other, the index difference An is twice the index change in either arm. This halves the required voltage.

is usually called Vn. By operating in a push-pull manner, with the index change increasing in one arm and decreasing in the other, the index difference An is twice the index change in either arm. This halves the required voltage.

Note that the transmitted light is periodic in phase difference (and therefore voltage). The response depends only on the integrated phase shift and not on the details of its spatial evolution. Therefore, nonuniformities in the electro-optically induced index change that may occur along the interferometer arms do not affect the extinction ratio. This property has made the interferometric modulator the device of choice in communications applications.

For analog applications, where linear modulation is required, the modulator is prebiased to the quarter-wave point (at voltage![]() . and the transmission efficiency becomes linear in

. and the transmission efficiency becomes linear in![]() (for moderate excursions):

(for moderate excursions):

The electro-optic effect depends on the polarization. For the electrode configuration shown here, the applied field is in the plane of the lithium niobate wafer, and the polarization of the light to be modulated must also be in that plane. This will be the case if a TE-polarized semiconductor laser is butt-coupled (or lens-coupled) with the plane of its active region parallel to the lithium niobate wafer, and if the wafer is Y-cut. Polarization-independent modulation requires a different orientation, to be described later. First, however, we discuss the electrode requirements for high-speed modulation.

High-Speed Operation

The optimal modulator electrode design depends on how the modulator is to be driven. Because the electrode is on the order of 1 cm long, the fastest devices require traveling wave electrodes rather than lumped electrodes. Lower-speed modulators use lumped electrodes, in which the modulator is driven as a capacitor terminated in a parallel resistor matched to the impedance of the source line. The modulation speed depends primarily on the RC time constant determined by the electrode capacitance and the terminating resistance. To a smaller extent, the speed also depends on the resistivity of the electrode itself. The capacitance per unit length is a critical design parameter. This depends on the material dielectric constant and the electrode gap-to-width ratio G/W. The capacitance-to-length ratio decreases and the bandwidth-length product increases essentially logarithmically with increasing G/W. At G/W = 1, C/L = 2.3 pF/cm and AfRCL = 2.5 GHz cm. The tradeoff is between large G/W to reduce capacitance and a small G/W to reduce drive voltage and electrode resistance. The ultimate speed of lumped electrode devices is limited by the electric transit time, with a bandwidth-length product of 2.2 GHz cm. The way to achieve higher speed modulation is to use traveling wave electrodes.

The traveling wave electrode is a miniature transmission line. Ideally, the impedance of this coplanar line is matched to the electrical drive line and is terminated in its characteristic impedance. In this case, the modulator bandwidth is determined by the difference in velocity between the optical and electrical signals (velocity mismatch or walk-off), and any electrical propagation loss. Because of competing requirements between a small gap to reduce drive voltage and a wide electrode width to reduce RF losses, as well as reflections at any impedance transition, there are subtle trade-offs that must be considered in designing traveling-wave devices.

Lithium niobate modulators that operate at frequencies out to 8 GHz at 1.55 |im wavelength are commercially available, with operating voltages of <4 V.44 Typical modulators have <5 dB insertion loss and >20 dB extinction ratio. To operate near quadrature, which is the linear modulation point, a bias voltage of ~10 V is required. Direct coupling from a laser or polarization-maintaining fiber is required, since these modulators are not independent of polarization. Traveling wave modulators operating well beyond 20 GHz have been reported in the research literature.

Insertion Loss

Modulator insertion loss can be due to Fresnel reflection at the lithium niobate-air interfaces, which can be reduced by using antireflection coatings or index matching (which only helps, but does not eliminate this loss, because of the very high refractive index of lithium niobate). The other cause of insertion loss is mode mismatch. The diffusion process must make a deep waveguide. Typically, the waveguide will be 9 |im wide and 5 |im deep. While the in-plane mode can be gaussian and can match well to the fiber mode, the out-of-plane mode tends to be asymmetric, and its depth must be carefully optimized. In an optimized modulator, the coupling loss per face is about 0.35 dB and the propagation loss is about 0.3 dB/cm. This result includes a residual index-matched Fresnel loss of 0.12 dB.

Misalignment can also cause insertion loss. An offset of 2 |im typically increases the coupling loss by 0.25 dB. The angular misalignment must be maintained below 0.5° in order to keep the excess loss below 0.25 dB.40

Propagation loss comes about from absorption, metallic overlay, scattering from the volume or surface, bend loss, and excess loss in the Y-branches. Absorption loss at 1.3- and 1.55-^m wavelengths appears to be <0.1 dB/cm. Bend loss can be large, unless any curvature of guides is small. The attenuation coefficient in a bend has the form:

where C1 = 15 mm-1 and C2 = 0.4 mm-1 in titanium indiffused lithium niobate, at wavelengths around 1.3 to 1.5 |im. This means that a 5-mm-long section of constant radius 20 mm will introduce only 0.1 dB of excess loss.45

A final source of loss in Y-branches is excess radiation introduced by sharp transitions. These branches must be fabricated carefully to avoid such losses, since the tolerances on waveguide roughness are critically small.

Polarization Independence

As previously shown, if the light is incident along the Z axis and the field is along the Y axis, then light polarized along X and Y experience the same phase shift, but opposite signs. An X-cut crystal, with an in-plane field along Y, therefore, provides polarization-independent interferometric modulation at the sacrifice of somewhat higher half-wave voltage (e.g., 17 V).46 Because of the difficulty of achieving exactly reproducible lengths in the two arms of the Y-branch interferometer, it has been found useful to do a postfabrication phase correction using laser ablation.

Photorefractivity and Optical Damage

Lithium niobate exhibits photorefractivity, also called optical damage when it is a nuisance. This phenomenon is a change in refractive index as a result of photoconduction originating in weak absorption by deep traps and a subsequent redistribution of charges within the lithium niobate. Because the photoconductive crystal is electro-optic, the change in electric field resulting from charge motion shows up as a change in refractive index, altering the phase shift as well as the waveguiding properties. While photorefractivity seriously limits the performance of lithium niobate modulators at shorter wavelengths (even at 850 nm),47 it is not a serious concern at 1.3 and 1.55 |im.

However, partial screening by photocarriers may cause a drift in the required bias voltage of modulators, and systems designers may need to be sensitive to this.

Delta-Beta Reversal Modulators

Early designs for modulators used a configuration entitled the delta-beta reversal modulator. This is based on the concept of the directional coupler. When two parallel waveguides are situated close enough that their evanescent fields overlap, light couples between them. If they are identical, light can oscillate completely between them, similar to the coupling of energy between two coupled pendula. When they are not identical, the coupling occurs more rapidly, and there is not complete transfer of energy between the two guides. A modulator can be built, then, by using a field applied to one guide to destroy their synchronicity and therefore their coupling.48 This has not proven to be practical, however, both because of fabrication difficulties and because of residual effects due to photo refractivity. These modulators are not discussed further here.

![tmp8-613_thumb[2][2][2][2][2][2]_thumb tmp8-613_thumb[2][2][2][2][2][2]_thumb](http://what-when-how.com/wp-content/uploads/2011/09/tmp8613_thumb222222_thumb_thumb.png)

![tmp8-615_thumb[2][2][2][2][2][2]_thumb tmp8-615_thumb[2][2][2][2][2][2]_thumb](http://what-when-how.com/wp-content/uploads/2011/09/tmp8615_thumb222222_thumb_thumb.png)

![tmp8-616_thumb[2][2][2][2][2][2]_thumb tmp8-616_thumb[2][2][2][2][2][2]_thumb](http://what-when-how.com/wp-content/uploads/2011/09/tmp8616_thumb222222_thumb_thumb.png)

![tmp8-617_thumb[2][2][2][2][2][2]_thumb tmp8-617_thumb[2][2][2][2][2][2]_thumb](http://what-when-how.com/wp-content/uploads/2011/09/tmp8617_thumb222222_thumb_thumb.png)

![tmp8-623_thumb[2][2][2][2][2][2]_thumb tmp8-623_thumb[2][2][2][2][2][2]_thumb](http://what-when-how.com/wp-content/uploads/2011/09/tmp8623_thumb222222_thumb_thumb.png)

![tmp8-625_thumb[2][2][2][2][2][2][2] tmp8-625_thumb[2][2][2][2][2][2][2]](http://what-when-how.com/wp-content/uploads/2011/09/tmp8625_thumb2222222_thumb.png)

![tmp8-626_thumb[2][2][2][2][2][2][2] tmp8-626_thumb[2][2][2][2][2][2][2]](http://what-when-how.com/wp-content/uploads/2011/09/tmp8626_thumb2222222_thumb.png)

![tmp8-631_thumb[2][2][2][2][2][2][2] tmp8-631_thumb[2][2][2][2][2][2][2]](http://what-when-how.com/wp-content/uploads/2011/09/tmp8631_thumb2222222_thumb.png)

![tmp8-642_thumb[2][2][2][2][2][2][2] tmp8-642_thumb[2][2][2][2][2][2][2]](http://what-when-how.com/wp-content/uploads/2011/09/tmp8642_thumb2222222_thumb.png)