INTRODUCTION

Optical communication systems utilize fiber optics to transmit the light that carries the signals. Such systems require optoelectronic devices as sources and detectors of such light, and they need modulators to impress the telecommunication signals onto the light. This topic outlines the basics of these devices. Characteristics of devices designed for both high-performance, high-speed telecommunication systems (telecom) and for low-cost, more modest performance data communication systems (datacom) are presented. Sources for telecom are edge-emitting lasers, including double heterostructure (DH), quantum well (QW), strained layer (SL), distributed feedback (DFB), and distributed Bragg reflector (DBR) lasers. Operating characteristics of these edge-emitting lasers include threshold, light-out versus current-in, spatial, and spectral characteristics. The transient response includes relaxation oscillations, turn-on delay, and modulation response. The noise characteristics are described by relative intensity noise (RIN), signal-to-noise ratio (SNR), mode partition noise (in multi-mode lasers), and phase noise (which determines linewidth). Frequency chirping broadens the linewidth, described in the small and large signal regime; external optical feedback may profoundly disturb the stability of the lasers and may lead to coherence collapse.

Semiconductor lasers usually have a laser cavity in the plane of the semiconductor device, and emit light out through a cleaved edge in an elliptical output pattern. This output is not ideally suited to coupling into fibers, which have circular apertures. Low-cost systems, such as datacom, put a premium on simplicity in optical design. These systems typically use multi-mode fibers and surface-emitting light-emitting diodes (LEDs). The LEDs are less temperature dependent than lasers and are more robust, but they typically are slower and less efficient. Those LEDs applicable to fiber optics are described here, along with their operating and transient response characteristics. Edge-emitting LEDs have some niche fiber-optic applications and are briefly described.

Recently, vertical cavity surface-emitting lasers (VCSELs) have been developed, which have vertical laser cavities that emit light normal to the plane of the semiconductor device. Fibers couple more easily to these surface-emitting sources, but their laser performance is usually degraded compared to that of the edge-emitting sources. This topic outlines typical VCSEL designs (material, optical, and electrical); their spatial, spectral, and polarization characteristics; and their light-out versus current-in characteristics. While most VCSELs are GaAs-based, rapid progress is being made toward long-wavelength InP-based VCSELs.

The most common modulators used in fiber-optic systems today are external lithium nio-bate modulators. These are usually used in Y-branch interferometric modulators, created by phase modulation from the electro-optic effect. These modulators are introduced here, along with a discussion of high-speed modulation, losses, and polarization dependence, and a brief description of optical damage and other modulator geometries. These devices provide chirp-free modulation that can be made very linear for applications such as cable TV.

An alternative modulator uses semiconductors, particularly quantum wells. This design has the advantage of allowing for more compact devices and monolithic integration. Typically, these are intensity modulators using electroabsorption. By careful design, the chirp in these modulators can be controlled and even used to counteract pulse spreading from chromatic dispersion in fibers. The quantum-confined Stark effect is described, along with the pin waveguides used as modulators and techniques for their integration with lasers. Their operating characteristics as intensity modulators, their chirp, and improvements available by using strained quantum wells are presented.

Some semiconductor modulators use phase change rather than absorption change. The electro-optic effect in III-V semiconductors is discussed, along with the enhanced refractive index change that comes from the quantum-confined Stark effect, termed electrorefraction. Particularly large refractive index changes result if available quantum well states are filled by electrons. The field-dependent transfer of electrons in and out of quantum wells in a barrier, reservoir, and quantum well electron transfer (BRAQWET) structure enables a particularly large refractive index change modulation. Phase-change modulators based on this principle can be used in interferometers to yield intensity modulators.

Detectors used in fiber systems are primarily pin diodes, although short descriptions of avalanche photodetectors (APDs) and metal-semiconductor-metal (MSM) detectors are provided. The geometry, sensitivity, speed, dark current, and noise characteristics of the most important detectors used in fiber systems are described.

Most of the devices discussed in this topic are based on semiconductors, and their production relies on the ability to tailor the material to design specifications through epitaxial growth. This technology starts with a bulk crystal substrate (usually the binary compounds GaAs or InP) and employs the multilayered growth upon this substrate of a few micrometers of material with a different composition, called a heterostructure. Ternary layers substitute a certain fraction x for one of the two binary components. Thus, AlxGa1 _ xAs is a common ternary alloy used in laser diodes. Another common ternary is InxGa1 – xAs. Layers are lattice matched when the ternary layers have the same size lattice as the binary; otherwise, the epitaxial layer will have strain. Lattice-matched epitaxial layers require that the substituting atom be approximately the same size as the atom it replaces. This is true of Al and Ga, so that AlxGa1 – xAs ternary layers are lattice matched to GaAs. The lowest-cost lasers are those based on GaAs substrates with AlxGa1 – xAs ternary layers surrounding the active layer. These lasers operate at wavelengths near the bandgap of GaAs, about 850 nm, and are typically used in low-cost data communications (as well as in CD players).

The wavelengths required for laser sources in telecommunications applications are those at which the fiber has the lowest loss and/or dispersion, traditionally 1.55 and 1.3 |im. There is no binary semiconductor with a bandgap at these wavelengths, nor is there a lattice-matched ternary. The InxGa1 – xAs ternary will be strained under compression when it is grown on either GaAs or InP, because indium is a much bigger atom than gallium, and arsenic is much bigger than phosphorus. The way to eliminate this strain is to use a fourth small atom to reduce the size of the lattice back to that of the binary. This forms a quaternary. The hetero- structure most useful for fiber-optics applications is based on InP substrates. The quaternary InxGa1 – xAs^P1 -y is commonly used, with the compositions x and y chosen to simultaneously provide the desired wavelength and lattice match. These quaternary heterostructures are the basis for much of the long-wavelength technology: sources, modulators, and detectors.

The reader is referred there for general information. This topic is specific to characteristics that are important for fiber communication systems.

DOUBLE HETEROSTRUCTURE LASER DIODES

Telecommunications sources are usually edge-emitting lasers, grown with an active laser layer that has a bandgap near either 1.55 or 1.3 |im. These are quaternary layers consisting of InxGa1 – xAsyP1 – y, grown lattice-matched to InP. The materials growth and fabrication technology had to be developed specifically for telecommunication applications and is now mature. These lasers are more temperature sensitive than GaAs lasers, and this fact has to be incorporated into their use. For telecom applications they are often provided with a thermoelectric cooler and are typically provided with a monitoring photodiode in the laser package, in order to provide a signal for temperature and/or current control.

Today’s telecom systems use single-mode fibers, which require lasers with a single spatial mode. In order to avoid dispersion over long distances, a single frequency mode is necessary. These requirements constrain the geometry of laser diodes (LDs) used for telecom applications, as discussed in the next section. Following sections discuss the operating characteristics of these LDs and their transient response and noise characteristics, both as isolated diodes and when subject to small reflections from fiber facets. The modulation characteristics of these diodes are discussed, along with frequency chirping. Advanced laser concepts, such as quantum well lasers, strained layer lasers, and lasers with distributed reflection (DFB and DBR lasers), are also introduced.

A typical geometry of an edge-emitting InGaAsP/InP laser is shown in Fig. 1. The active quaternary laser region is shown crosshatched. It is from this region that light will be emitted. Traditionally, these active regions have uniform composition and are lattice matched to the substrate. More advanced laser diodes, often used for telecom applications, have active regions containing one or more quantum wells and may be grown to incorporate internal strain in the active region. Both these characteristics are described in a separate section later in this topic.

The design of a double heterostructure laser diode requires optimization of the issues discussed in the following subsections.

Injection of a Population Inversion into the Active Region

This is necessary so that stimulated emission can take place. This is done by placing the active region between p and n layers, and forward-biasing the resulting diode. Electrons are injected into the active region from the n side and holes are injected from the p side; they become free carriers. Efficient electrical injection requires high-quality ohmic contacts attached to the n and p layers; electrical current through the junction then drives the laser.

Confinement of Carriers Within the Plane of the Active Layer

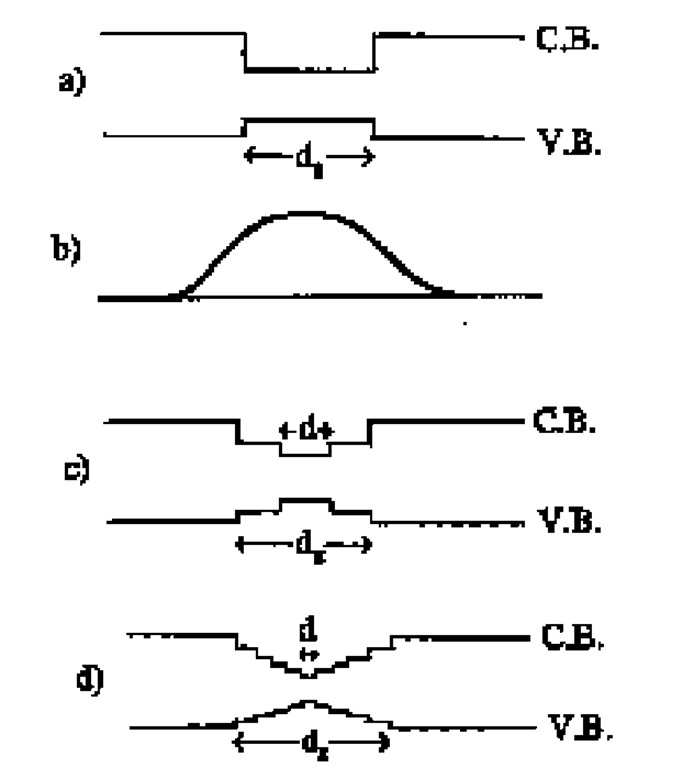

This is done by growing the active region as a thin layer of thickness d and surrounding it with layers of wider bandgap material, as shown in Fig. 2a. In quaternary lasers, wider bandgap material is provided by decreasing x and y relative to their values in the active region.

FIGURE 1 Typical geometry for an edge-emitting long-wavelength laser diode, as used in telecommunication systems. Light travels back and forth between cleaved mirror facets, confined to the active InGaAsP region by the buried heterostructure, and is emitted out of the crosshatched region, where it diffracts to the far-field. The current is confined to the stripe region by the current-blocking npn structure on either side.

Stimulated emission during electron-hole recombination in the narrow bandgap active layer provides the laser light. The thinner the active layer, the higher its gain. When the active layer thickness is as small as a few tens of nanometers, the free electron and hole energy levels become quantized in the growth direction, and the active layer becomes a quantum well (QW). Quantum wells have higher gain than bulk semiconductor active layers, and thus one or more quantum wells are often used as the active layers (see separate section later in this topic).

Confinement of Light Near the Active Layer

Stimulated emission gain is proportional to the product of the carrier and photon densities, so that edge-emitting lasers require the highest possible light intensity. This is done by containing the light in an optical waveguide, with a typical light profile as shown in Fig. 2b. To achieve optical confinement, the layers surrounding the waveguide must have lower refractive index. It is fortunate that higher-bandgap materials that confine carriers also have smaller refractive index, and so the active layer automatically becomes a waveguide.

Proper optical confinement requires a single waveguide mode. This means that the waveguide layer must be thinner than the cutoff value for higher-order modes. The waveguide thickness dg must be small enough that

where ng is the refractive index of the waveguide layer (usually the active layer), nc is the refractive index of the surrounding cladding (usually the p and n layers), and![]() , where

, where![]() is the free-space wavelength of the laser light. Typically,

is the free-space wavelength of the laser light. Typically,![]() The parameter V is usually introduced to characterize a waveguide.

The parameter V is usually introduced to characterize a waveguide.

If the waveguide is too thin, however, the waveguided optical mode spreads out beyond the waveguide layer. The fraction of optical power rg (called the waveguide confinement factor) that remains in the waveguide layer of thickness dg is given approximately by1:

FIGURE 2 Conduction band (CB), valence band (VB), and guided optical mode as a function of position in the growth direction, near the active region in typical semiconductor laser geometries: (a) double heterostruc-ture (DH) band structure, in which free carriers and light are both confined in the same region of small-bandgap material (of width dg), surrounded by higher-bandgap cladding material; (b) near-field spatial profile for light guided in layer of width dg; (c) separate confinement het-erostructure (SCH) band structure, in which the free carriers are confined in a smaller active region (of width d) than the optical wave; and (d) graded index separate confinement heterostructure (GRINSCH), in which the composition of the cladding is graded in order to focus the light more tightly to the active region (deepest well) containing the free carriers.

As dg becomes small, the confinement factor becomes small. When the carriers are confined in very thin layers, such as in quantum wells, the electrical carrier confinement layer cannot serve as an effective optical waveguide because the confinement factor is too small. Then a thicker waveguide region is used, and the photons and carriers are separately confined in a geometry called a separate confinement heterostructure (SCH), as shown in Fig. 2c. In this case the optical confinement factor, defined by the fraction of photons in the active layer of thickness d, is r = rg(d/dg).

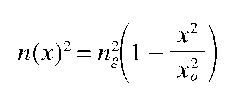

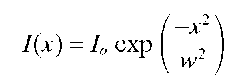

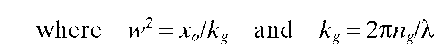

The light can be more effectively focused into a thin active layer by grading the refractive index in the separate confinement region, called a graded index SCH (GRINSCH) laser, shown in Fig. 2d. This graded refractive index is produced by growing material with varying bandgaps within the waveguide layer. Grading can be achieved by several discrete layers, as shown, or by grading many ultrathin layers with slight compositional differences. In either case, the focusing property of a GRINSCH structure can be approximated by fitting the graded refractive index to a parabolic refractive index profile n(x) such that:

where xo is related to the curvature of the refractive index near![]() where

where

![]() The mode guided by this profile has a gaussian beam-intensity profile:

The mode guided by this profile has a gaussian beam-intensity profile:

Limiting Carrier Injection to Stripe Geometry

Lasers are most efficient when the drive current is limited to the width of the optically active laser area. This requires defining a narrow stripe geometry electrode by means of a window etched in an isolating oxide layer or by ion implantation to render either side of the stripe resistive. More complex laser structures, such as those used in telecommunications applications, often define the conductive stripe electrode by using current-blocking npn layers grown on either side of the electrode, as shown in Fig. 1. The npn layers, consisting of back-to-back diodes, do not conduct current.

Injected carriers do not usually need lateral confinement, except to achieve the highest possible efficiency. Lateral free-carrier confinement will occur as a by-product of lateral optical confinement, which is discussed next.

Lateral Confinement of Light

The simplest laser diode structures do not specifically confine light laterally, except as the result of the stripe geometry carrier injection. These are called gain-guided lasers because high gain in the stripe region, due to the presence of free carriers, introduces a complex refractive index that guides the light laterally. Gain-guided lasers tend to be multimode (both lateral spatial modes and longitudinal frequency modes) unless the stripe is very narrow (<10 |im). In this case, the spatial far-field pattern has "rabbit ears," a double-lobed far-field pattern that is typically not very useful for coupling into single-mode fibers. Thus, gain-guided lasers are not usually used for telecommunications.

High-quality single-mode lasers for telecom applications typically require a means for creating a real refractive index difference laterally across the laser. The lowest threshold lasers use buried heterostructure (BH) lasers, the geometry shown in Fig. 1. After most of the layers are grown, the sample is taken out of the growth chamber and a stripe geometry mesa is etched. Then the sample is returned to the growth chamber, and one or more cladding layers with lower refractive index (higher bandgap) are grown, typically InP, as shown in Fig. 1. When the regrowth is planar, these are called planar buried heterostructure (PBH) lasers. The result is a real refractive index guide in the lateral dimension. The width of these index-guided laser stripes may be anything from 1 |im to more than 10 |im, depending on the refractive index difference between the active stripe and the lateral cladding material. Equation (1), which specifies the condition for single mode, applies here, with dg as the width of the lateral index guide and nc defined by the regrown material. A typical lateral width for low-threshold BH lasers is 3 |im.

A laser geometry that is much simpler to fabricate and has a higher reliability in production than that of BH lasers is the ridge waveguide (RWG) laser, shown in Fig. 3. The fabrication starts with the growth of a separate confinement heterostructure (sometimes with the addition of a thin etch-stop layer just after the top waveguide layer), followed by a stripe mesa etch down to the waveguide layer, finishing with planarization and contacting to the stripe. The etch leaves a ridge of p-cladding material above the waveguide layer, which causes strip loading, raising the effective refractive index locally in the stripe region, thereby creating lateral confinement of the light. Although the RWG laser is attractive because of its easy fabrication process, its threshold current is relatively high.

Retroreflection of Guided Light Along the Stripe

Light is usually reflected back and forth inside the laser cavity by Fresnel reflection from cleaved end facets. Since the waveguide refractive index is ng ~ 3.5, the natural Fresnel reflectivity at an air interface,![]() This rather low reflectivity means that semiconductor lasers are high gain, requiring enough amplification that 70 percent of the light is regenerated on each pass through the active medium.

This rather low reflectivity means that semiconductor lasers are high gain, requiring enough amplification that 70 percent of the light is regenerated on each pass through the active medium.

Relying on Fresnel reflection means that both facets emit light. The light emitted out the back facet may be recovered by including a high-reflectivity multilayer coating on the back facet, as is typically done in most telecom lasers. Sometimes a coating is also provided on the front facet in order to alter its reflectivity, typically to lower it, which increases the output power (as long as the gain is high enough to overcome the large loss upon reflection). The reflectivities must be such that the laser can obey the laser operating condition, which states that in a single round-trip through a laser of length L, the increase in optical power from gain must balance the reduction from finite reflectivity, so that their product is unity. That is,

where R1 and R2 are the reflectivities of the two facets and gL is the modal gain per unit length (as experienced by the waveguided laser mode), with a subscript L to represent that the gain is measured with respect to length. If R1 = R2 = 0.3, then gLL = 1.2. Typical laser diodes have lengths of 400 |im, so gL ~ 30 cm-1.

FIGURE 3 Geometry for a ridge waveguide (RWG) laser, fabricated by a single epitaxial growth followed by a mesa etch and planarization with polyimide. Light is confined to the region under the p-InP etched mesa by strip loading, which increases the effective refractive index in the waveguide region under the etched mesa.

In-plane retroreflection can also be achieved by using distributed feedback created from a grating impressed on top of the active layer. This method enables the construction of distributed feedback (DFB) lasers and distributed Bragg reflector (DBR) lasers, which are discussed later in a separate section.

Mounting so that Light is Edge-Emitted

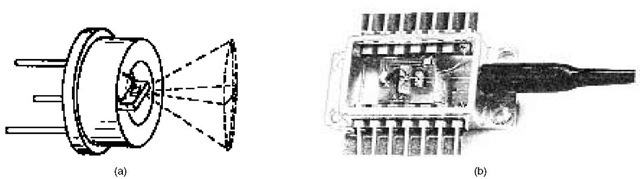

Because the light is emitted out of the facet laterally, there must be a clear optical path for the light as it exits the laser. In many cases, the light is mounted with the active layer down, very close to the copper (or diamond) heat sink, in order to maximize cooling.2 In this case, the laser chip must be placed at the very edge of the heat-sink block, as shown in Fig. 4a.

In some cases, the laser is mounted with its active region up with its substrate next to the heat sink. The edge alignment is not so critical in this case, but of course the laser light will still be emitted in a direction parallel to the plane of the heat sink. Because the thermal conductivity of the heat sink is much higher than that of the substrate, only the lowest threshold lasers, operating at moderate power levels, are operated with the active region up.

Suitable Packaging in a Hermetic Enclosure

Water vapor can degrade bare facets of a semiconductor laser when it is operating; therefore, LDs are usually passivated (i.e., their facets are coated with protective layers), and/or they are placed in sealed packages. The LD may be placed in a standard three-pin semiconductor device package, such as a TO-46 can with an optical window replacing the top of the can, as shown in Fig. 4a. The LD should be situated near the package window because the light diverges rapidly after it is emitted from the laser facet. The package window should be anti-reflection coated because any light reflected back into the laser can have serious consequences on the stability of the output (see Sec. 3.5).

Many high-end applications require an on-chip power monitor and/or a controllable thermoelectric cooler. In this case a more complex package will be used, typically a 14-pin "butterfly" package, often aligned to a fiber pigtail, such as is shown in Fig. 4b. In the less expensive datacom applications, nonhermetic packages may be acceptable with proper capping and passivation of the laser surfaces.

FIGURE 4 Packaging laser diodes: (a) typical hermetically sealed package showing heat sink and emission pattern for a laser diode with its active region placed down on a copper (or diamond) heat sink; and (b) typical butterfly package, showing laser in the middle, monitoring photodiode (behind), and fiber alignment chuck in front, all mounted on a thermoelectric cooler.

Fiber Pigtail Connection

Because light diverges at a rather large angle as it comes out of an edge-emitting laser (as discussed later), it is often desirable to use a laser provided with a fiber pigtail, which is a pre-aligned length of fiber that can be spliced or connected to the telecom fiber in the field. There will be an inevitable reduction in output power (compared to that of a laser with no pigtail) because of finite coupling efficiency into the pigtail, but the output will be immediately useful in a telecom system. The alternative to using a fiber pigtail is the use of a microlens—often a graded index (GRIN) lens, discussed elsewhere in this volume.

Long Life

Early lasers showed degradation with running time, but those problems have been solved, and it is expected that the semiconductor lasers used in telecom systems should last hundreds of thousands of hours. However, this requires that care be taken in their use. In particular, large reverse-bias static voltages can break down the pn diode. Thus, protection from electrostatic shock while handling and from reflected reverse-bias electrical currents during operation should be maintained. In addition, if LDs are driven with too much forward-bias current, the optical output can be so large that the light may erode the facet out of which it is emitted. Since the threshold is strongly temperature dependent, a laser driven at constant current that becomes too cold can emit too much light, with resulting optical damage. Thus, many telecom lasers have monitoring photodiodes to control the laser output and ensure that it stays within acceptable bounds.