Abstract

The purpose of this paper is to provide an overview of the principles, features, benefits, and limitations of the building conditioning technology called underfloor air distribution (UFAD) and the closely related task/ ambient conditioning (TAC).

INTRODUCTION AND BACKGROUND

Recent trends in today’s office environment make it increasingly more difficult for conventional centralized heating, ventilation, and air-conditioning (HVAC) systems to satisfy the environmental preferences of individual office workers using the standardized approach of providing a single uniform thermal and ventilation environment. Since its original introduction in West Germany during the 1950s, the open plan office, containing modular workstation furniture and partitions, is now the norm. Thermostatically controlled zones in open plan offices typically encompass relatively large numbers of workstations in which a diverse work population having a wide range of preferred temperatures must be accommodated. Modern office buildings are also being impacted by a large influx of heat-generating equipment (e.g., computers and printers) whose loads may vary considerably from workstation to workstation. Offices are often reconfigured during the building’s lifetime to respond to changing tenant needs, affecting the distribution of within-space loads and the ventilation pathways among and over office partitions. Compounding this problem, there has been growing awareness of the importance of the comfort, health, and productivity of individual office workers, giving rise to an increased demand among employers and employees for a high-quality work environment.

Underfloor Air Distribution

In the 1970s, underfloor air distribution (UFAD) was introduced into office buildings in West Germany as a solution to cable management and heat load removal issues caused by the proliferation of electronic equipment throughout the office.[13] In these buildings, the comfort of the office workers had to be considered, giving rise to the development of occupant-controlled localized supply diffusers to provide task conditioning. Some of the first UFAD systems in Europe used a combination of desktop outlets for personal comfort control and floor diffusers for ambient space control.[12]

Prior to the 1990s, office installations using underfloor systems were found primarily in South Africa, Germany, and other parts of Europe. The technology was not commonly used in North America before about 1995, in part due to the downturn in office building construction beginning in the mid-1980s. Japan did not experience this same downturn, and as aresult, significant growth in UFAD technology was observed during this period. Between 1987 and 1995, more than 250,000 m2 (2.7 million ft2) of office space in more than 90 buildings was installed with UFAD systems in Japan.[14]

However, in the late 1990s, growth for raised floor installations in the United States was dramatic, and designers and manufacturers predicted that 35% of new offices would use raised floors by 2004. Half of these installations were expected to incorporate UFAD technology. This rate of increase slowed in 2003 due to the economic downturn and reduced office construction, but has revived since then. Installation data shows that since 2005, 12% of new commercial offices used raised floors, and 45% of those projects used UFAD systems.[11] We estimate that as of 2006, at least 400 UFAD projects have been built in North America.

Task/Ambient Conditioning (TAC)

During recent years, an increasing amount of attention has been paid to air distribution systems that individually condition the immediate environments of office workers within their workstations to address the issues outlined above. As with task/ambient lighting systems, the controls for the task components of TAC systems are partially or entirely decentralized and under the control of the occupants. Typically, the occupant has control over the speed and direction, and in some cases the temperature, of the incoming air supply. Variously called “task/ambient conditioning,” “localized thermal distribution,” and “personalized air conditioning,” these systems have been mostly installed in open-plan office buildings to which they provide supply air and (in some cases) radiant heating directly into workstations.

Fig. 1 Illustration of typical swirl diffuser used in underfloor air distribution (UFAD) systems.

TECHNOLOGY DESCRIPTION UFAD Systems

Underfloor air distribution systems use the open space (underfloor plenum, also used for distribution of other services such as power and computer cabling) between a structural slab and the underside of a raised floor system to deliver conditioned air to supply diffusers (Fig. 1) located at or near floor level within the occupied zone (up to 6-ft [1.8-m] height) of the space. The supply diffusers can provide some degree of individual control over the local thermal environment, depending on diffuser design and location. Additional supply diffusers provide ambient environmental control in nonwork areas. Active diffusers (for purposes of this paper) are defined as those with local means of volume adjustment (such as an integral variable speed fan or damper) that is amenable to automatic zone control (in addition to means for occupant control). Passive diffusers, although they may have means for occupant adjustment, are combined with terminal or system elements to achieve zone control. Systems designed with all fan-assisted active diffusers typically use zero-pressure plenums. Passive diffusers require pressurized plenums. The majority of UFAD systems currently being deployed have pressurized plenums with either active or passive diffusers.

TAC Systems

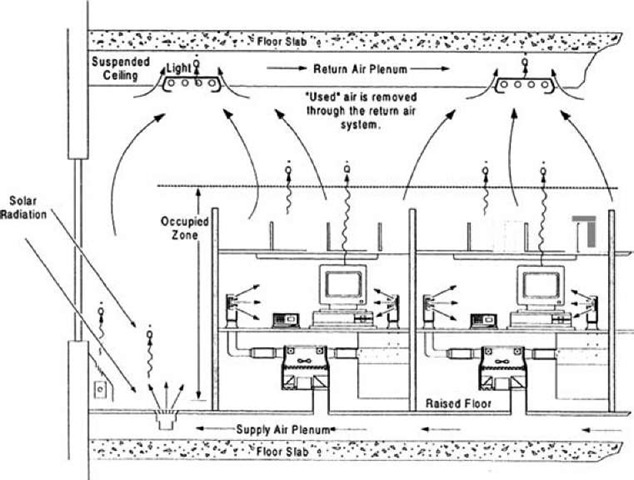

Task/ambient conditioning systems can be distinguished from standard UFAD systems by their higher degree of personal comfort control provided by the localized supply outlets. Task/ambient conditioning supply outlets use direct velocity cooling to achieve this level of control, and are therefore most commonly configured as fan-driven (active), jet-type diffusers that are part of the furniture or partitions or from floor outlets. A majority of TAC systems deployed have used UFAD to distribute conditioned air to fan-driven diffusers located in workstation furniture and partitions. Fig. 2 shows an illustration of such a TAC system.

For further information on a complete range of TAC systems, refer to Bauman et al. and Loftness et al.[6'10] Because few TAC systems are currently (as of 2006) being deployed, the remainder of this report will be focused only on UFAD systems.

PRINCIPLES OF OPERATION OF UFAD SYSTEMS

Figs. 3 and 4 illustrate the fundamental differences between traditional overhead and UFAD systems, respectively. As shown in Fig. 3, overhead systems (in office buildings, these are predominately variable air volume (VAV) all-air distribution systems) employ an extensive array of ductwork and terminal devices to provide supply air through the ceiling-mounted diffusers. Often referred to as mixing ventilation systems, these systems are designed to promote complete mixing of supply air with room air, thereby maintaining the entire volume of air in the space at the desired temperature setpoint. Space air is typically returned to the AHU through an open ceiling plenum that also contains various other systems for lighting, electrical, communications, and fire protection.

Fig. 2 Task/ambient conditioning (TAC) system.

Underfloor air distribution systems turn this concept upside down and have the following characteristics:

• Supply air, including at least the minimum required volume of outside air, is filtered and conditioned to the required temperature and humidity by a conventional AHU and passed through a minimum amount of ductwork to an underfloor plenum. The underfloor plenum is formed by installation of a raised floor system, typically consisting of 0.6 X 0.6 m (2X 2 ft2) of concrete-filled steel floor panels positioned 0.3-0.46 m2 (12-18 in.) above the concrete structural slab of the building. The raised floor system also allows all cable services, such as power and communication, to be located in the plenum and provides easy access for modifications and maintenance.

• Individual office workers can control their local thermal environment to some extent (typically by adjusting the volume and/or trajectory of the supply air entering the space), giving them the opportunity to fine-tune the thermal conditions in their workstation to their personal comfort preferences. Different supply outlet configurations may be used depending on the conditioning requirements for a particular zone of the building, as discussed below.

Fig. 3 Overhead system.

Fig. 4 Pressurized plenum underfloor air distribution (UFAD) system.

• Underfloor air distribution systems benefit from a floor-to-ceiling airflow pattern that takes advantage of the natural buoyancy produced by heat sources in the office to efficiently remove heat loads and contaminants from the space. Air is returned from the room at ceiling level through recessed lighting fixtures and return grilles through a conventional ceiling return plenum or return grilles located high in the space when a return plenum is not used.

• Because the air is supplied directly into the occupied zone (up to 6-ft [1.8-m] height), supply outlet temperatures are generally maintained above 17°C-18°C (63°F-64°F) to avoid uncomfortably cool conditions for the nearby occupants and to minimize cool temperature near the floor.

There are a wide variety of approaches being used to provide a combination of individual and automatic zone control for UFAD systems.[2] The authors have identified over a dozen variations of these systems. Typically, these systems use VAV or constant-air-volume (CAV) methods for general zone control (i.e., overall zone control other than local occupant control).

• Six types of diffusers are currently being offered:

— Fan-assisted, active

— Variable area, active

— Swirl, passive

— Swirl, active

— Linear bar grille, passive

— Linear bar grille, active

• The heating and cooling loads of perimeter zones are handled by fan-powered constant volume or variable volume terminal reheat units located in the underfloor plenum (similar to those shown in Fig. 4). Passive or active diffusers are located in occupied areas of the zone, normally within about 4.5 m (15 ft) from the exterior walls. Passive diffusers are generally supplied by a (series) fan-powered mixing box or fan coil unit, or a VAV box either connected to the diffuser by ducting or by supplying air to a partitioned area of the plenum where the diffusers are located.

• Interior zones are generally large zones each controlled by one thermostat, but with diffusers located near the occupants within or close to their workstations.

Fig. 4 shows a schematic diagram and Fig. 5 shows a typical swirl diffuser layout for a pressurized plenum UFAD system.

This system is being commonly applied to office buildings due to its simplicity and cost savings. Although

Fig. 5 Typical interior swirl diffuser layout for underfloor air distribution (UFAD) systems.

this floor-based air distribution system provides somewhat limited individual comfort control for occupants, it still retains the same flexibility and potential energy-saving benefits associated with the others.

POTENTIAL OF UFAD APPLICATIONS Benefits

Improved Thermal Comfort for Individual Occupants

Occupant thermal comfort is perhaps the area of greatest potential improvement in that UFAD systems potentially can accommodate individual differences. In today’s work environment, there can be significant variations in individual comfort preferences due to differences in clothing and activity level (metabolic rate), as well as differences in the local heat gains and losses. By allowing personal control of the local thermal environment, UFAD systems could potentially satisfy virtually all occupants, including those out of thermal equilibrium with their surrounding ambient environment, as compared with the 80% satisfaction quota targeted in practice by existing thermal comfort standards.[1]

Improved Air Movement and Ventilation Effectiveness; Cleaner Environment

Some amount of improvement over conventional uniformly mixed systems is expected by delivering the fresh supply air near the occupant and at the floor.

Improved Occupant Satisfaction and Increased Worker Productivity

Underfloor air distribution systems have the potential to increase the satisfaction and productivity of occupants, because occupants have the ability to individually control their workspace environments. The financial implications of such improvements can be extremely large, as salary costs typically make up at least 90% of all costs (including construction, operation, and maintenance) over the lifetime of a building.

Energy Savings

Energy savings over conventional overhead systems are predominately associated with two factors: (1) cooling energy savings from economizer operation at higher supply air temperatures and (2) fan energy savings due to reduced static pressure requirements and potentially lower airflow requirements due to optimized stratification. Additional details of how these savings are achieved can be found in Bauman and Bauman and Lehrer.[2'3]

LIMITATIONS

Among the items that limit the widespread acceptance and application of UFAD technology are the following.

New and Unfamiliar Technology

For the majority of U.S. building owners, developers, architects, engineers, and equipment manufacturers, UFAD systems still represent a relatively new and unfamiliar technology. The decision to select a UFAD system will initially require changes in common practice, including new procedures and skills in the design, construction, and operation of such systems, as well as changes in responsibilities of the various installation trades. This situation creates some amount of perceived risk to designers and building owners. Significant progress has been made in these practices over the past several years.

Perceived Higher Costs

Many designers are concerned about the higher first costs of the raised flooring required for UFAD systems. However, as described above, there are many factors associated with raised floor systems that contribute to reducing life-cycle costs in comparison to traditional air distribution systems. (See the “Cost Effectiveness” section below). In a recent study of UFAD costs, we found that there are several ways that UFAD systems can be tailored to reduce the cost differential. Furthermore, the difference depends significantly on the quality of the traditional VAV system being used for comparison.1-16-1

Limited Applicability to Retrofits and Certain Building Types/Areas

The installation of UFAD systems and the advantages that they offer are most easily achieved in new construction. Some of the key system features are not always suitable for retrofit applications (e.g., access floors cannot be installed in existing buildings with limited floor-to-floor heights). Although widely applicable, there are some building types and areas within buildings where access floors and UFAD are not appropriate. These areas are generally those in which spillage has the potential to occur, including bathrooms, laboratories, cafeterias, and shop areas.

Lack of Information, Design Guidelines, and Evaluation Methods

Although in recent years there has been an increased number of publications on UFAD technology, only very recently has there been effort aimed at providing a complete understanding of the underlying fundamental fluid mechanics and thermal issues to allow for the creation of design and simulation tools. New guidelines and research results are presented in several sources.[4'5'9'15'17] System commissioning procedures, operating sequences, and control techniques are likewise under development.

Potential for Higher Building Energy Use

As with any space conditioning system, a poorly designed and operated UFAD system has the potential to use more energy than that of a well-designed conventional system. Other factors that can influence the energy comparison with conventional systems are number of perimeter fan-powered units, supply plenum thermal decay in UFAD systems, and airflow requirements.

Thermal Discomfort

Underfloor air distribution systems are perceived by some to produce cold floor, and because of the close proximity of supply outlets to the occupants, the increased possibility of excessive draft exists. However, we are finding that thermal comfort problems are more likely to be associated with inadequate control and operating strategies and inexperience of operators with UFAD technology.

Plenum Leakage

There have been reports of problems with leakage from the supply plenums either into the space (through floor penetrations and floor panel leakage) or through bypassing the occupied space to the return or outside the building altogether. This latter type of leakage, if excessive, is a serious problem, because it causes increased fan energy use. This is probably the single most serious problem found upon start-up of UFAD projects to date and can be traced to poor design and construction practices related to the leakage sources.

Virtually all of the issues listed above are actively being researched (refer to References) or addressed by design and construction professionals and equipment vendors in response to market demand. Some issues suggested by critics of UFAD technology have turned out not to be problems, and many of the problems that do occur can be traced to inadequate design, construction, and operating practices that have resulted from lack of knowledge and experience. Problems like these are typical for early installations of any nascent technology.

COST EFFECTIVENESS

Cost considerations will be different depending on whether the installation represents new or retrofit construction. Total first costs (shell and core plus tenant improvement) for UFAD systems using raised flooring will likely be somewhat higher than those for a conventional system. Preliminary results from research studies1-16-1 have shown total building first costs of pressurized UFAD systems in new construction (including raised floor and structural differences) to be about $3.50 per gross square foot (gsf) greater than typical practice conventional VAV systems. However, if a raised floor system has already been justified for other reasons, such as improved cable management, or a high quality conventional system is the standard of comparison, the cost premium is effectively eliminated altogether, and under some circumstances, there can be savings in the range ~ $2-7/gsf. In new construction, UFAD can lead to reducing floor-to-floor heights, thus reducing structural costs. Furniture-based and active diffuser-based systems will generally cost more than other solutions.

Operating costs can be reduced in accordance with the energy-saving strategies discussed above. With the improved thermal comfort and individual control provided by UFAD systems, occupant complaints requiring response by facility staff can be minimized. Underfloor air distribution systems using raised flooring provide maximum flexibility and significantly lower costs associated with reconfiguring building services (when changes are being made in the office layout) due to churn, and thus reduce life-cycle costs substantially.

| Table 1 Example churn rates | ||

| Office plan (% office/ | ||

| Group | Churn (%) | open/bullpen) |

| Services | 37 | 35/55/10 |

| Manufacturing | 40 | 34/58/8 |

| Institutional/ | 23 | 67/20/13 |

| fovernment | ||

First cost for retrofits, generally the bulk of construction activity, is most likely greater than those for new construction. Also, as indicated previously, some facilities are not amenable to retrofit by UFAD systems.

In order to determine total life-cycle cost differences between UFAD systems and conventional designs, the following factors must be considered in addition to first cost:

• Churn. This is the cost associated with relocating personnel and it is defined as the ratio of total workplace moves in a year to the total number of building occupants. These figures vary widely by industry type and building activities. Results of a study by IFMA[8] are shown in Table 1.

As shown, government facilities have significantly lower churn than other industries, which is also reflected in the much lower percentage of open plan space. This indicates that the benefits of reduced churn costs in federal facilities may be limited. It should be noted that the cost of churn can vary considerably depending on the extent of the reconfiguration; i.e., simply moving to a new cubicle is much different that reconfiguring the layout of cubicles or offices. The high proportion of private offices in government facilities could drive these costs significantly if the reconfiguration involves more than office to office moves.

• Operations and maintenance (O&M). This item includes the costs of maintenance and repair as well as energy. While energy savings estimates are limited due to the lack of appropriate capabilities in energy simulation programs and data from monitored projects, indications are that savings in annual HVAC system energy can be in the range of 0%-20% depending on system design and weather conditions. Maintenance costs are expected to be less than conventional systems due to the ease of access to the distribution system. However, commissioning/startup costs may be greater because the location and operation of the diffusers may require fine-tuning to optimize the occupant interaction benefits.

• Productivity and health. The savings associated with productivity and health benefits are difficult to measure and require considerably more research. However, recent studies[7] indicate that work performance improvements of 0.5%-5% may be possible if the indoor environmental quality is improved.

SUMMARY AND CONCLUSIONS

Underfloor air distribution systems have significant potential advantages compared with traditional VAV systems. Rarely has there been a space conditioning technology that promises the combined benefits of improvements in thermal comfort, energy efficiency, and productivity and health. Underfloor air distribution technology, like all nascent technologies, is being advanced both in theory and practice by researchers, designers, manufacturers, and early adopter owners who are working to bring the design, operation, and costs to the point where they can be more easily and reliably applied. Underfloor air distribution technology may someday displace overhead VAV as the system of choice for space conditioning. Although the use of UFAD systems in particular is becoming more common in the private commercial sector, the overall potential for UFAD in federal facilities may be limited by low churn that reduces life-cycle cost benefits. In addition, the overall federal building stock is not as amenable to UFAD installations as the private sector, due to the higher cost of retrofits (i.e., a greater ratio of fixed private offices).

However, in those situations where it is appropriate, there are many compelling reasons to consider UFAD for the space conditioning solution.