5.6

When applying polyphase induction motors to adjustable-frequency power supplies, it must be remembered that the induction motor nameplate rating is based on a fixed-frequency, fixed-voltage, sine-wave voltage source. Therefore, the application of polyphase

induction motors with adjustable-frequency power supplies requires consideration of additional features that are not considered for fixed-frequency motor applications.

5.6.1

Types and Characteristics of Loads

Most electric motor loads fall in one of the following categories:

Variable-torque loads Constant-torque loads Constant-horsepower loads Cyclical, intermittent, or varying loads

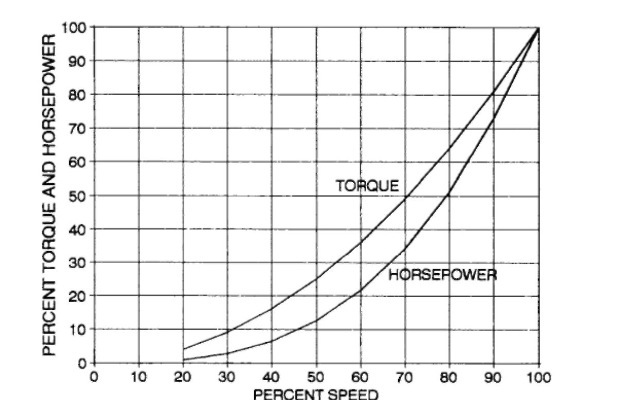

Variable-Torque Loads. For this type of load, the torque usually increases as the square of the speed, and the horsepower increases as the cube of the speed. This type of load is typical of fans and centrifugal pumps within their normal operating range. The characteristic of a variable-torque load is illustrated in Fig. 5.9. The

FIGURE 5.9 Load characteristics for variable-torque loads.

selection of the induction motor horsepower rating when supplied by a non-sine-wave power source for a variable-torque load can be based on the following:

Standard motor, derated to 85 or 90% of nameplate

horsepower rating Standard motor with 1.15 service factor, no derating

Energy-efficient motor, no derating

Since the horsepower required by the variable-torque load increases as the cube of the driven speed, the motor will be overloaded if it is operated above its base speed.

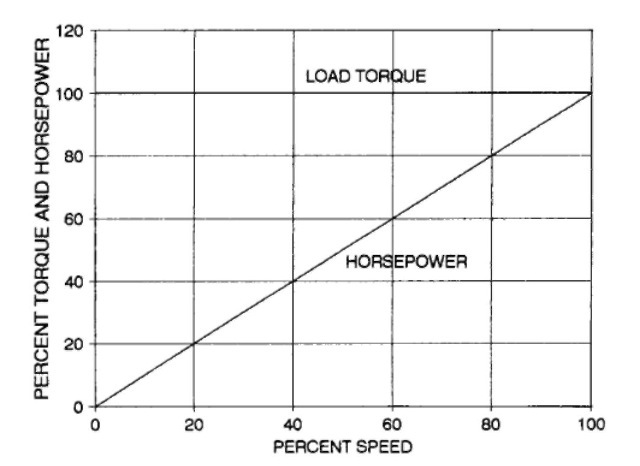

Constant-Torque Loads. The motor torque required for this type of load is constant over the operating range and is not a function of speed. The motor horsepower required is proportional to the output speed. Typical constant-torque loads are conveyors, cranes, positive-displacement pumps, and mixers. The characteristic of this type of load is illustrated in Fig. 5.10. The selection of the motor horsepower

FIGURE 5.10 Load characteristics for constant-torque loads.

rating for constant-torque loads depends on the speed range of continuous operation.

1. For 2-to-1 speed range (i.e., 60-30 Hz) continuous operation:

a. Standard motors derated 85-90% of nameplate horsepower

b. Standard motors, class F insulation, 1.15 service factor, no derating

c. Energy-efficient motors, no derating

2. For 6-to-1 speed range continuous operation (i.e., 60-10

Hz):

a. Standard motors, increase up to two sizes over the base horsepower required.

b. Standard motors, class F insulation, 1.15 service factor, increase up to one size over base horsepower required.

c. Energy-efficient motors, increase up to one size over base horsepower required.

d. For operation below 10 Hz, special cooling for the motor usually required.

e. For more specific information, consult the motor manufacturer and the inverter manufacturer.

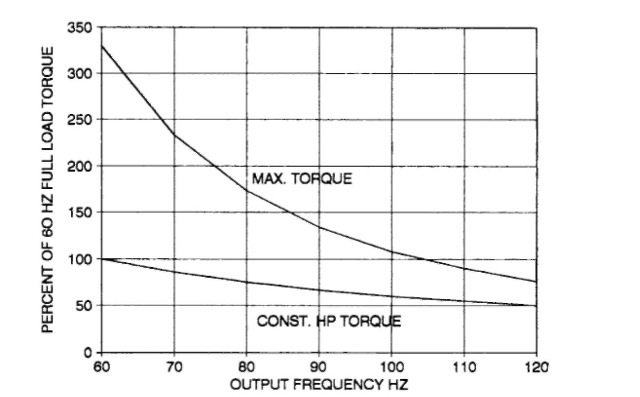

Constant-Horsepower Loads. For a constant-horsepower load, the load torque decreases as the speed increases, and the horsepower required remains essentially constant. This type of load is typical of metal-cutting machinery operating at a constant cutting or grinding velocity. As the diameter of the work is decreased, the drive speed is increased to maintain constant cutting velocity. The operating range is above base speed (i.e., 60 Hz and higher); therefore, the induction motor base speed must be selected so that at the maximum operating speed, the safe operating speeds of the induction motor and the driven equipment are not exceeded. The motor manufacturer and the equipment manufacturer should be consulted to determine the maximum safe speed for the system. These types of drives generally operate at a fixed voltage above base speed rather than constant

volts/hertz. It must be determined that the induction motor will develop the horsepower required over the speed range required. Figure 5.11 shows the operating capability of a 10-hp standard induction motor in the constant-horsepower range (i.e., 60-120 Hz), and Fig. 5.12 illustrates the load characteristic for a constant-horsepower load.

Cyclical and Intermittent Loads. These types of loads require special consideration in sizing both the induction motor and the adjustable-frequency power supply. The motor manufacturer and the adjustable-frequency power supply manufacturer should be consulted for these types of applications.

5.6.2

Characteristics of an Induction Motor Operating on an Adjustable-Frequency Power Supply

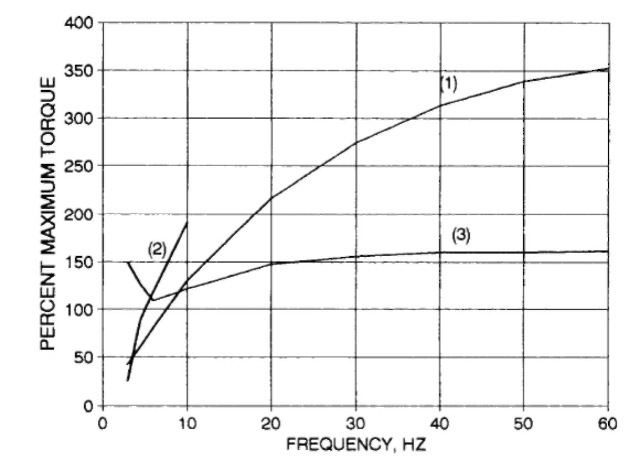

Induction Motor Torques. The polyphase induction motor has a unique speed-torque curve at each frequency when operated at constant volts/hertz. This family of speed-torque curves is illustrated

FIGURE 5.11 Performance of a 10-hp induction motor in the constant-horsepower range.

FIGURE 5.12 Load characteristics for constant-horsepower loads.

in Fig. 5.13 for a 100-hp, 1800-rpm, energy-efficient induction motor. The utilization of the motor torque capability depends on the current restriction imposed by the adjustable-frequency power supply. In most cases, the power inverter has a limit of 150% of its current rating for 1 min. Figure 5.14 illustrates the maximum torque (breakdown torque) capabilities of a 10-hp, four-pole induction motor under various voltage and current conditions. The maximum torque at 150% of motor rated current requires voltage boosts below 10 Hz, with the percent of voltage boost increasing as the frequency is decreased. The motor and adjustable-frequency power supply cannot operate continuously at these values of torques and current. These torques are important, however, when determining the acceleration time for high-inertia loads since the 150% current can be maintained only by the adjustable-frequency power supply for about 60 sec.

The locked-rotor torque or breakaway torque is a function of both the voltage and frequency applied to the motor. The locked-rotor torque per ampere increases as the frequency decreases, and the voltage is at constant volts/hertz down to about 6 Hz. The stator

FIGURE 5.13 Speed-torque curves at constant volts/hertz for 100-hp, 1800-rpm, energy-efficient induction motor.

resistance may limit the torque that the motor develops at 6 Hz and lower. Figure 5.15 illustrates the low-frequency locked-rotor performance for a 10-hp, four-pole induction motor as a function of frequency and applied voltage. Locked-torque values at locked current equal to full-load current are shown by curve 2, Fig. 5.15. The voltages to achieve these values of torque are shown by curve 3, Fig. 5.15. This represents considerable voltage boost below about 3 Hz. Curve 4, Fig. 5.15, illustrates the voltage boost required to obtain locked torque equal to full-load torque. This indicates that locked torque equal to full-load torque can be obtained at rated voltage at about 6 Hz.

The actual value of locked-rotor torque or breakaway torque available depends on the motor characteristics and on the voltage boost capability of the adjustable-frequency power supply.

The starting torque and acceleration torque requirements may be a consideration, depending on the type of load and the inertia of the connected load. For most pumps and fans, this is usually not a

FIGURE 5.14 Maximum torque (BDT) for a 10-hp, four-pole induction motor. (1) Maximum torque (BDT) at constant volts/hertz. (2) Maximum torque (BDT) with 20% voltage boost. (3) Maximum torque (BDT) at 150% rated current (with voltage boost below 10 Hz).

problem. However, for a large fan with high inertia or other types of loads with high inertia such as a large flywheel, the time to accelerate the load becomes important. This time to accelerate the load can be expressed as

where

t = time to accelerate, sec

WK2 = moment of inertia of load referred to the motor plus the

motor inertia, lb-ft2 RPM = change in speed, i.e., low speed to high speed T = net accelerating torque

FIGURE 5.15 Locked-rotor performance at low frequencies for a 10-hp, four-pole, 60-Hz induction motor.

(1) Percent locked torque at constant volts/hertz. (2) Percent locked torque at locked current equal to full-load current. (3) Percent voltage for locked current equal to full-load voltage. (4) Percent voltage for locked torque equal to full-load torque.

The net accelerating torque is the difference between the motor torque available and the torque required to drive the load. The motor torque available is a function of the voltage and current limitations imposed on the motor by the adjustable-frequency power supply. Therefore, the combination of the motor and adjustable-frequency power supply must be selected so that the load can be accelerated within the current-time constraint of the power supply and the acceleration time required for the application.

Induction Motor Efficiency. The efficiency of polyphase induction motors at constant-torque loads decreases as the frequency is decreased with constant-volt/hertz input. Figure 5.16 illustrates the efficiency of a 100-hp, 1800-rpm standard induction motor at various

FIGURE 5.16 Efficiency of 100-hp, constant volts/hertz 1800-rpm standard motor at , sine power.

loads and frequencies when operated from a sine-wave power source. Similarly, Fig. 5.17 illustrates the performance of a 100-hp, 1800-rpm energy-efficient induction motor at various loads and frequencies when operated from a sine-wave power source.

Note that the energy-efficient motor has higher efficiency at all loads and frequencies and that this difference becomes more significant as the frequency is decreased. When the power source to the induction motor is nonsinusoidal and contains harmonics, additional losses, particularly stator and rotor winding losses and stray losses, are generated in the induction motor. The magnitude of the increased losses depends on the harmonic frequencies and voltages in the power source and also on the induction motor design.

Generally, the energy-efficient types of polyphase induction motors have a smaller increase in harmonic losses than the standard induction motors because of their lower stator and rotor resistances. Induction motors with deep-bar or T-bar rotors have higher

FIGURE 5.17 Efficiency of 100-hp, 1800-rpm energy-efficient motor at constant volts/hertz, sine power.

har-monic losses than induction motors with shallow-bar rotors. Induction motors with double-cage rotor construction can have excessive harmonic losses.

Figures 5.18 and 5.19 illustrate the increases in losses or decrease in efficiency for a particular motor/adjustable-power supply combination. There are no typical values for the increase in losses due to the harmonics since the increase depends on the magnitude and frequency of the harmonics generated by the adjustable-frequency power supply and the motor reaction to these harmonics. The increase in losses can range from as low as 10% to over 50%. Figure 5.20 shows a comparison of the efficiencies of a 100-hp, 1800-rpm standard motor and a 100-hp energy-efficient motor when supplied by a non-sine power source. Note the superior performance of the energy-efficient motor.

The six-step type of adjustable-frequency power supply generally causes a larger increase in induction motor losses than the pulse width modulation adjustable-frequency power supply.

FIGURE 5.18 Comparison of a 100-hp, 1800-rpm standard motor efficiency with a sine-wave and a non-sine-wave power source.

FIGURE 5.19 Comparison of a 100-hp, 1800-rpm energy-efficient motor efficiency with a sine-wave and a non-sine-wave power source.

FIGURE 5.20 Efficiency comparison of a 100-hp, 1800-rpm energy-efficient motor versus a 100-hp, 1800-rpm standard motor, both with non-sine power.

Induction Motor Thermal Capacity. The induction motor nameplate identifies the type of motor enclosure, class of insulation, and service factor that the motor is rated for. These features determine the thermal capability of the motor. However, this rating is based on a sine power supply at rated voltage and frequency.

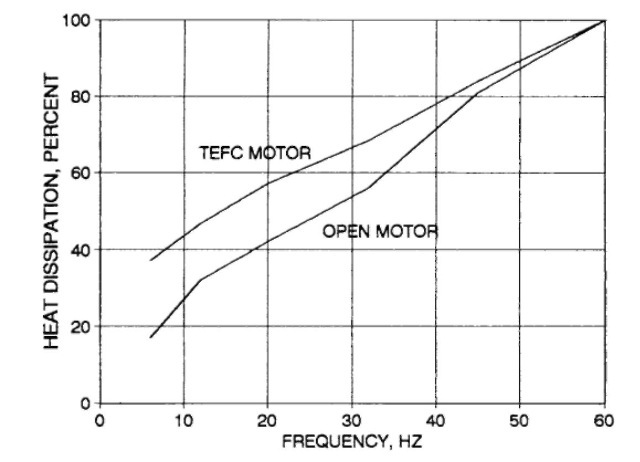

The heat dissipation of an induction motor depends on the class of insulation used in the motor, allowable temperature rise, ventilation, and type of enclosure. This varies from one motor manufacturer to another. However, in general, the allowable heat dissipation relative to the base-speed (60-Hz) heat dissipation decreases with speed (frequency) as shown in Fig. 5.21. Note that the heat-dissipation ability of the totally enclosed fan-cooled (TEFC) motor does not decrease as fast as that of the open motor. This is due to the ability of the TEFC to dissipate more of the heat generated by radiation and natural convection when operating at low speeds. The final temperature rise of the motor depends on heat-producing losses that must be dissipated, which are a function of the load,

FIGURE 5.21 Relative heat-dissipation ability as a function of motor frequency (speed).

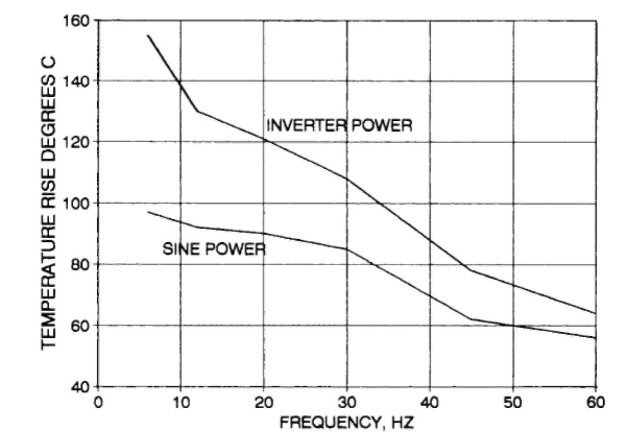

FIGURE 5.22 Temperature rise for a 5-hp, 1800-rpm open motor operating on a sine-wave power source versus an inverter power source.

speed, and harmonic losses caused by the motor input voltage. Again, the six-step adjustable-frequency power supply produces higher harmonic losses in the motor than the pulse width modulation power supply and results in higher motor temperatures.

The operation of a 5-hp, open, 1800-rpm induction motor on sine power supply and on an inverter with non-sine power supply are compared in Fig. 5.22. This figure compares the temperature rise for the same output torque at each frequency. The load was constant down to 30 Hz and was reduced at 20 Hz and lower to obtain constant temperature rise on the tests with the inverter power supply.

5.6.3

Summary: Induction Motor Selection for Adjustable-Frequency Inverter Systems

1. Define the load characteristics:

a. Starting or breakaway torque required

b. Type of load, i.e., variable torque, constant torque, constant horsepower, or cyclical

c. Base horsepower

d. Speed range for continuous operation

e. Acceleration time and load inertia

2. Define the type of adjustable-frequency inverter.

3. Determine the motor horsepower rating and derating based on the torque requirements, speed range, and thermal capacity, considering the constraints imposed on the motor by the adjustable-frequency inverter.