We have already noted how CHP units provide both heat and electricity. The next matter to be considered is whether it is worthwhile installing systems which solely produce electricity, often called ‘embedded generation’. For the individual home, the most common technology for this purpose is photovoltaic cells (PVs). Under present regulations in the UK and at current electricity prices this is not a cost-effective investment, despite the fact that government subsidies to offset the capital cost may be available. However, situations can change quite rapidly for several reasons:

• The unit cost of PV cells is likely to fall significantly in the near future.

• The European Union will be regularizing the electricity market in due course, ensuring that small generators receive a reasonable return for their investment. (In Germany, it is a profitable investment thanks to the Renewable Energy Law.)

• There will be increasing international pressure to reduce carbon dioxide emissions. The UK had made a commitment to reduce its emissions by 20 per cent by 2010 against 1990 levels. It has just been abandoned at the time of writing, no doubt because it would only be possible with a really ambitious programme of renewable energy.

• There is strong political and economic pressure to embrace the principle of distributed generation.

The final point calls for an explanation. Distributed generation means drawing electricity from a wide range of small power plants, down to the size of an individual home with PVs, CHP or a wind generator. Under the present arrangement, the national grid obtains its electricity from a small number of large power stations which then distribute the power over considerable distances. As stated earlier, this is a system which can be as low as 35 per cent efficient when line losses are taken into account. It is also vulnerable to failure due to severe weather. In the winter at the end of 2002, storm damage left some communities without power for weeks.

The US energy expert Carl J Weinberg affirms that ‘the conceptual model of a utility as large central power plants connected to customers by wires may well not be the model for the future’. This theme was taken up by the Royal Commission on Environmental Pollution which recommends, ‘a shift from large all-electricity plant towards more numerous combined heat and power plants. The electricity system will have to undergo major changes to cope with this development and the expansion of smaller scale renewable energy sources’ (22nd Report, Energy, The Changing Climate, (2000), p. 169).

Developments in information technology are the key to this energy transformation. It is now capable of managing the complexities of a system with a large number of distributed electricity producers without centralized control. It can deal with the interplay of supply and demand providing hour by hour the most equitable price balance between consumers and generators, however small they may be.

Photovoltaic cells (PVs)

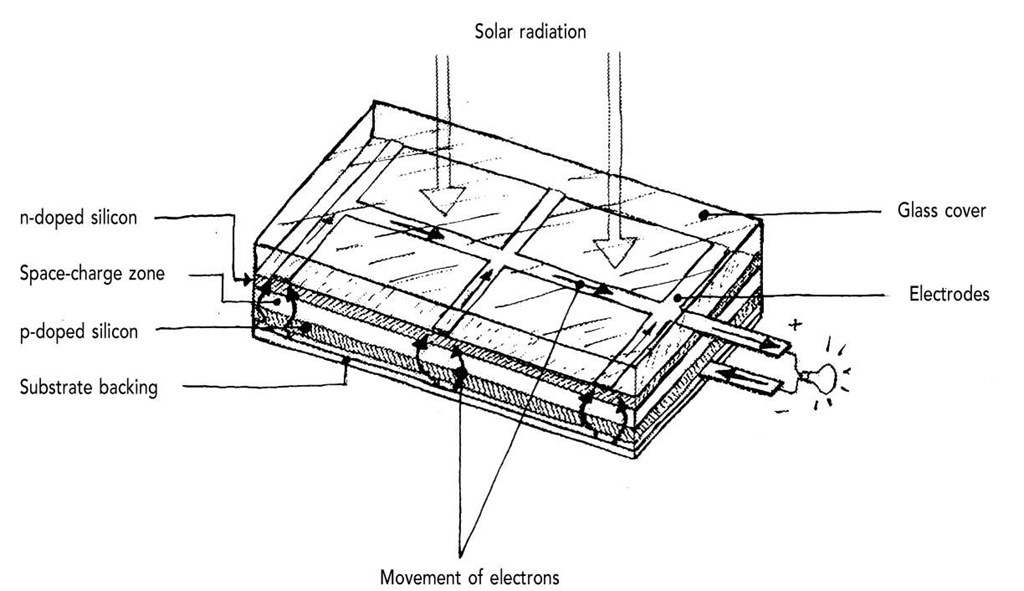

PVs are devices which convert light directly into electricity. At present, most PVs consist of two thin layers of a semi-conducting material, each layer having different electrical characteristics. In most common PV cells both layers are made from silicon but with different, finely calculated amounts of impurities: p-type and n-type. The introduction of impurities is known as ‘doping’. As a result of the doping, one layer of silicon is negatively charged (n-type) and has a surplus of electrons. The other layer is given a positive side (p-type) and an electron deficit. When light falls on a PV cell electrons are forced from one side to the other due to the radiative energy from the sun. Some of the electrons are captured as useful energy and directed to an external circuit (Figure 10.1).

Cells with different characteristics and efficiencies can be created by using different base and doping materials. The output is direct current (DC) which must be changed to alternating current (AC) by means of an inverter if it is to be fed to the grid. Converting to AC current involves a power loss. The Oxford University Environmental Change Institute compared two types of inverter. The one which operated better in the cloudy conditions of the UK was NKF OK4E. Achieving high efficiencies at low input power levels is an important feature of an inverter in the UK. Another device is required to ensure that the current is grid compatible which means 240 V at 50 Hz.

The capacity of cells to convert light into electricity is defined by Watts peak (Wp). This is based on a bench test and is the power generated by a PV under light intensity of 1000 W/m2, equivalent to bright sun. The efficiency of a cell is a function of both peak output and area. This is a laboratory measurement and does not necessarily give a true indication of energy yield.

Figure 10.1 Photovoltaic cell structure and function.

Monocrystalline silicon

At the time of writing, the most efficient PVs are monocrystalline silicon consisting of wafers of a pure crystal of silicon. They achieve a peak output of about 15 per cent. That means that 15 per cent of daylight is converted to electricity when daylight is at its maximum intensity. Due to the production processes involved these cells are expensive.

The solar cell size of around 10 x 10 cm has a peak output of about 1.5 W. To realize a usable amount of electricity cells are wired into modules which, in turn, are electrically connected to form a string. One or more strings form an array of modules.

The cells are sandwiched between an upper layer of toughened glass and a bottom layer of various materials, including glass, Tedlar or aluminium. It must be remembered that a number of linked cells produces a significant amount of current therefore during installation solar cells should be covered, whilst all the electrical connections are made.

Multicrystalline silicon

In the production process of this cell, molten silicon is cast in blocks containing random crystals of silicon. In appearance cells are blue and square. It is cheaper than a monocrystalline cell but has a lower efficiency ranging between 8 and 12 per cent.

A variation of silicon technology has been developed by Spheral Solar of Cambridge, Ontario. It has produced a flexible panel made of minute silicon beads sandwiched between two thin layers of aluminium foil sealed on both sides with plastic. Each bead converts sunlight into electricity with an efficiency of 11 per cent. It is much lighter than PVs currently available and can be shaped to follow almost any profile. It holds the promise of being an ideal retrofit PV panel for existing roofs. Commercial production is due to start in 2004 (New Scientist 15 February 2003. p. 19).

Amorphous silicon

This cell does not have a crystalline structure, but is stretched into thin layers which can be deposited on a backing material, which can be rigid or flexible. It is the first of a new breed of PVs based on thin film technology. By building up layers tuned to different parts of the solar spectrum known as a double or triple junction cell, a peak efficiency of 6 per cent is achievable. Unlike the crystalline cells, it is capable of bulk production and is therefore potentially cheaper.

Cadmium telluride (CdTe) and copper indium diselenide (CIS)

These cells are a further development of thin film technology, having efficiencies of about 7 and 9 per cent, respectively. At present, prices are comparatively high but will reduce as volume of sales increases.

In summary, costs range between £2 and £4 per Wp. However, unit cost is not necessarily the only criterion. Different cells have varying optimum conditions which have been highlighted by a research programme recently completed by the Oxford University Environmental Change Institute. This showed that the amount of electricity generated by a PV array rated at 1 kWp in 1 year varies considerably between different technologies. For example, CIS (Seimens ST 40) gave the best returns at over 1000 kWh per kWp per year in the UK. Double junction amorphous silicon cells were close behind. This is because these cells are more effective in the cloudy conditions so prevalent in the UK. Single junction amorphous silicon cells were the poorest performers. The best performing modules produced nearly twice as much power as the lowest yielding cells, so it is very much a case of ‘buyer beware’.

A sloping roof facing a southerly direction is the ideal situation, provided it is not overshadowed by trees or other buildings. However, east and west orientations can produce significant amounts of electricity. The optimum angle of tilt depends on latitude. In London, it is 35°. As a rough guide, in London 1 m2 of monocrys-talline PVs could produce 111 kilowatt hours of electricity per year. On low pitch or flat roofs it is advisable to mount the cells on tilt structures at the correct orientation. However, in the UK climate, a flat roof can still deliver 90 per cent of the optimum output.

Standard PV modules can easily be fixed to an existing roof. However, if a roof covering needs to be replaced, it then could become a cost-effective option to use solar slates, tiles or shingles to maintain a traditional appearance. The range of options offered by Solar Century is a useful indication of the possibilities available to the homeowner. A sample of their specifications is given in full, courtesy of Solar Century.

Solar shingles

Ideally suited to the UK climate, solar shingles use triple junction technology to produce electricity even on cloudy days (Figure 10.2).

Power, 17 Wp per tile

Efficiency, 6-7 per cent

Product size, Active area 138 x 2136 mm

Product weight, 6.9 kg/m2

Power per module, 17 W

Area per kWp, approximately 18 m2

Modules per m2, 3.26

Exposed area, width 2195 mm ± 6 mm, height 305 mm Total active area, 0.30 m2

Features

• Truly integrated solar PV roofing product

• Low visual impact

• Avoids planning difficulties

• No glass, therefore durable, no UV absorption

• Lightweight

• Easy to lay

• Low embodied energy

• Replaces existing tiles

• Self cleaning

• Triple junction means: works under low light conditions; more delivered power per peak Watt; better temperature coefficient; good for diffuse skies.

• Under temperate climate conditions a yield of about 860 to 950 kWh/kWp/year is possible. This figure is 10 to 20 per cent better than poly-crystalline PV.

• By-pass diode in every cell gives superior shading tolerance.

• 20 year warranty

Figure 10.2 (a, b) Solar shingles.

Sunslates

Individual slates that are fitted with high efficiency solar cells, designed to look and perform just like your normal roof slates. They are extremely versatile and are quick and easy to install, providing clean electricity all year round.

Sunslates® are suitable for any roofing situation where a conventional tile can be used and are installed on to the building just like normal roof tiles. The tiles fit to standard slate battens and the easy slate-to-slate connectors mean that installation is quick and easy, with no structural alterations required (Figure 10.3).

Figure 10.3 Sunslates.

Efficiency, 10 per cent

kWh per kWp (south facing at 30°), 750

Area per kWp, 10 m2

Actual size, 720 x 480 mm

Exposed size, 300 x 480 mm

Number and size of cells, 6 x 125 x 125 mm

Installed weight, 35.8 kg/m2

Features

• Sunslates are roof integrated, i.e. take the place of traditional roof tiles, so they fit seamlessly into the building design of any shaped roof.

• The systems have a good power output even in low light conditions, this means that they perform well, even in the unpredictable UK climate.

• Individual Sunslate connection sockets containing by-pass diodes enable the roof to generate electricity even if a tile is partly shaded.

• Sunslates are designed to blend in with the surrounding tiles, as well as the environment, so planning permission is only required in some conservation areas or on grade one listed properties.

• The tiles are fitted to the roof with standard storm hooks, providing just as much protection from high winds as traditional tiles.

• The tempered glass covering adds to the tile’s durability and their ability to withstand the rigours of the tough UK climate.

Glass laminates

Solar glass laminates are attractive and unusual, and provide electricity and insulation. They are available in a wide range of colours (Figure 10.4).

Glass laminates form the conservatory roof in the ‘Orange At Home’ house of the future. The glass used is very high quality and heat-strengthened. A resin layer is included to make them shatter-resistant. This also has the effect of making the laminates insulating, acting like double glazing. The solar cells within the laminates have the beneficial side effect of reducing glare. Solar glass laminates are made to order, to your specifications. You can decide on the colours, type of glass and how much light you want to let through.

Sunstation

These are retrofit modules that are fitted to the property’s original roof. A simple, cost-effective solar electric solution for the home. The Sunstation® is versatile and easy to install. It is an all-inclusive system, so no hidden costs or hassles. In most cases Solar Century can install your Sunstation® in just 1 day. The Sunstation® is modular and comes in different system sizes, enabling you to mix and match to suit your requirements and your budget (Figure 10.5).

Figure 10.4 (a, b) Glass laminates.

Figure 10.5 (a, b) Sunstation.

Sunstation® 8 panel System size, 0.96 kWp Electricity, 750k Wh CO2, 585 kg Area, 7.8 m2 Weight, 121.2 kg

Sunstation® 12 panel System size, 1.44 kWp Electricity, 1100 kWh CO2, 770 kg Area, 11.7 m2 Weight, 176.8 kg

To maximize the contribution of a south-facing sloping roof, it would also be useful to install flat bed solar thermal collectors integrated with PV modules (Figure 10.6).