ABSTRACT

A novel dynamic ring-on-ring equibiaxial flexural testing technique with single pulse loading capability is established on a modified Kolsky bar. This technique is then utilized to investigate the loading-rate and surface-condition effects on the flexural strength of a borosilicate glass. Quasi-static and dynamic experiments are performed at loading rates ranging from 5×10-1 to 5×106 MPa/s. It is found that the flexural strength of the borosilicate glass strongly depends on the applied loading rates. HF acid corrosion on the surface promotes the flexural strength to above 1.3 GPa. Fractographic analysis shows that surface modification has changed the type of flaws that govern the flexural strength of glass samples.

INTRODUCTION

Over the past several decades, vast amount of research has been carried out to explore the biaxial flexural strength of glass and ceramic materials [1]. However, it was only until recently that these studies have been expanded to dynamic loading conditions, for which the data are of great desire to the high speed impact applications. Cheng et. al [2] tested the dynamic biaxial flexural strength of a thin ceramic substrate with a modified piston-on-three-ball testing configuration. In these experiments, dynamic loading is applied on the center of the specimen through a thin incident bar driven by a force hammer. Except under extremely high pressure or temperature, the failure of brittle materials under impact is controlled by flaw nucleation, propagation, and coalescence. Flexural tests on glass materials suggested that the shape and severity of surface flaws are the key factors in strength determination. Consequently, the dynamic biaxial bending behavior of glass materials should be determined together with the loading-rate and surface-flaw effects. In this paper we studied the surface-flaw and loading-rate effects on the biaxial flexural strength of a borosilicate glass utilizing a modified Kolsky bar, with its testing section customized into a ring-on-ring equibiaxial bending configuration. Pulse shaping technique is applied on the Kolsky bar to ensure both force equilibrium and constant loading rate in the specimen. It is found that the flexural strength of the borosilicate glass increases with increasing loading rates under all surface conditions. The HF acid etching promotes glass surface tensile strength by a factor of 4 under equibaxial bending, while sandpaper grinding compromises strength for over 50% due to the severe surface flaws introduced by abrasive particles.

EXPERIMENTS AND RESULTS

The calculated strength values for borosilicate glass samples at different loading rates and surface conditions are summarized in Table 1. The results indicate that the surface modifications significantly affect the flexural strength of the glass material. The sandpaper grinding degrades the strength by 60-70% from the as-polished surface condition. However, HF acid etching on as-polished specimens promotes the surface tensile strength by 200-400%, depending on the applied loading rates. The experimental results also indicate that the loading rate has remarkable effects on the flexural strength. Under all surface conditions tested, the strength universally increases with loading rates. But the rate of strength increase levels out at the loading rate of ~3,500 MPa/s.

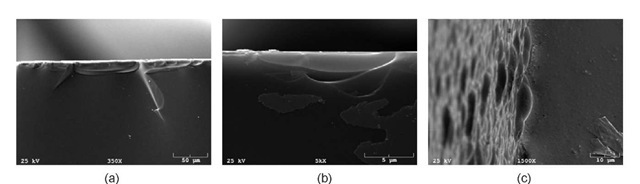

The observed strength variations under different surface conditions stimulated further fractography investigations to better understand the fracture mechanisms of borosilicate glass under equibiaxial flexural loading conditions. In this research, fracture surface images were taken by scanning electron microscopy (SEM) and are shown in Fig. 1. For the sandpaper-ground samples, sharp cracks that penetrate into the sub-surface are visible at the center of the fracture zone. Further polishing on the as-ground surfaces resulted in reduction of critical crack size, and thus an increase in flexural strength. The strength governing flaw size on HF acid etched surface is similar to that on the as-polished surface, whereas the flexural strength of the etched sample is four times higher than that of as-polished samples. The fracture surface of an etched sample reveals that failure was initiated from a severe surface pit. However, no sharp front of a pre-crack was identified. This indicates that the fracture of an etched specimen is originated from a blunt surface flaw, unlike the case of as-polished specimens where a sharp surface crack is located in the failure origin. As a result, although acid etching developed similar flaw depths as is possessed by as-polished samples, the blunt nature of etching pits offers much less stress intensity compared to the sharp crack front in polished samples, and thus raises the flexural strength significantly.

Table 1. Equibiaxial flexural strength of borosilicate glass under different loading rates and surface conditions.

|

Loading rate |

0.52 MPa/s |

42 MPa/s |

3500 MPa/s |

5×106 MPa/s |

|

HF etched |

352 ± 35.7 |

744 ± 96 |

1267 ± 124 |

1383±137 |

|

As-polished |

146 ± 11 |

180 ± 13 |

245 ± 15 |

255 ± 19 |

|

Sandpaper ground |

46 ± 3 |

52 ± 4 |

77 ± 8 |

83 ± 7 |

Figure 1. SEM images showing the fracture origins of glass samples receiving different surface modifications. (a) Ground by sandpaper, (b) As-polished, and (c) Polished and etched by HF acid. Fracture surfaces for acid-etched samples are taken from 4-point bending experiment for comparison purpose.