Projection Displays

Projection displays do not represent a separate class of fundamental display technology, as was the case with the above types, but rather are most often a different application of one of these technologies. This class of display is distinguished by a single common feature: rather than being directly viewed, the display device (or at least the image it creates) is imaged onto or through a passive surface (the projection screen) which is then the location of the image as seen by the user.

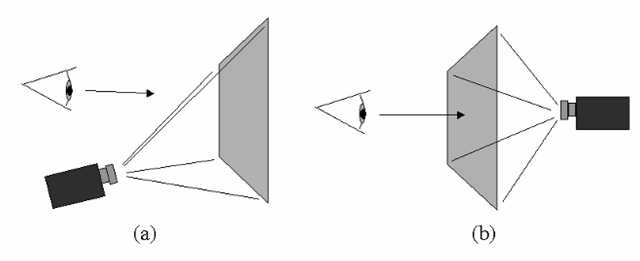

Again, this display class generally divides into two – those projections in which the display device itself produces the light (i.e., the display is of one of the emissive technologies), and those in which the device modulates (either in a transmissive or reflective mode) light produced by a separate source. The former type is almost without exception based on an rather extreme modification of the CRT, while the latter has in the past been dominated by liquid-crystal devices and is now a mix of LCD-based systems and those which employ one of the microdisplay technologies. Projection displays are also commonly distinguished by the optical path used; there are front-projection types (Figure 4-18a), in which the image source and the viewer are on the same side of the projection screen, and the image is viewed by reflection from the screen surface; and rear-projection types (Figure 4-18b), in which the image is projected to the rear of the screen (as seen by the viewer), and is observed through the translucent screen material.

As the length of the path from the projection optics to the screen is often not fixed, projection displays often are not specified by screen size, but rather solely by the light output by the projection optics. This figure, along with the screen size and characteristics, will deter-mine the “brightness” of the image as ultimately seen by the user.

Figure 4-18 Projection display systems are commonly classified as either front-projection (a), in which the viewer and image source are on the same side of a reflective screen, and rear-projection (b), in which the viewer and image source are on opposite sides of a translucent screen.

This is where the person familiar with the direct-view display types will often be shocked by an analysis of a projection system; the numerous sources of loss in the path from light source to screen will result in an overall light efficiency which may appear extremely low. It is not uncommon, in some very practical projection display systems, for less than 5% of the original light produced by the source to actually make it in usable form to the screen. It is rare for this figure to get much above 10% or so in all but the CRT types. Still, projection displays are often the only viable option for many applications, such as very-large-screen display (as in cinematic presentation) or as a portable, conference-room type of display. Projection is also beginning to compete well in some traditional direct-view markets, such as the larger desktop monitors and television displays. In these applications, it is not so much the overall efficiency of the optical path which matters, but how much total electrical power will be required by the display. And from this perspective, projection systems are becoming very competitive.

CRT projection

CRT-based projection systems operate by projecting the image generated by the CRT(s) onto the desired projection screen surface. While this could be done with a conventional direct-view CRT type, these do not produce sufficient light to be viable as the basis for a practical projection system. This is particularly true of the common tricolor CRT, which is already suffering from an efficiency problem due to the interception of significant beam current by the shadow-mask structure. For this reason – among others – CRT-based projection displays use very specialized tubes designed specifically for this purpose. These are relatively small-screen (round screens of 17.75 cm (7 inch) and 22.75 cm (9 inch) diameter are currently the most popular), long tubes, producing extremely bright, well-focused images which are then projected by the optical system. The larger-sized tubes not only provide (usually) more light output, but also can provide better focus, geometry, etc., and so are usually the preferred choice for high-resolution displays.

Since projection cannot afford the inefficiencies of the shadow-mask color CRT, full-color operation in such systems is generally achieved in one of two ways: either a single monochrome (white) tube is used in conjunction with a color-filter wheel, in a field-sequential color system; or three separate projection tubes (one with each of the three primary-color phosphors) are employed, with their separate images combined in the optical system. Currently, the three-tube system is by far the most common. Regardless of the number of tubes used, projection CRTs also differ from their direct-view cousins in one other significant regard. Due to the very high light output required, projection CRTs operate with very high beam currents directed to a relatively small screen. This would cause excessive heating and ultimately the rapid destruction of the screen surface, were some form of dedicated cooling not employed. Projection CRT screens may be cooled via circulating fluid (water, oil, or other optically suitable liquids) around and/or over the faceplate, or (if the heat to be dissipated is not excessive) through a passive fluid system which simply couples the heat to an external heat sink.

Display Applications

We have at this point looked at the basic operation of a very wide range of display technologies, both those in current use and several which hold promise for the future. Clearly, each brings its own unique set of advantages and handicaps to the market. These qualities, which can be compared in terms of cost, size, weight, image quality, environmental suitability, reliability, and the unique operating requirements for each type, result in each being well- or poorly suited to a given application. A comparison of the relative attributes of each technology is shown as Table 4-1.

Table 4-1 Relative attributes of various display technologies’1

|

Technology |

Bright |

Color |

Contrast |

Viewing angle |

Power |

Weight |

Cost |

|

CRT |

Good to excellent |

Very good |

Good to excellent |

Excellent |

High |

High |

Low |

|

Passive LCD |

Poor to fair |

Poor to fair |

Poor to good |

Poor to fair |

Very low |

Low |

Low to medium |

|

Active LCD |

Good to excellent |

Good to very good |

Fair to very good |

Fair to very good |

Low to medium |

Low to medium |

High |

|

OLED |

Very good to excellent |

Excellent |

Good to excellent |

Excellent |

Low to medium |

Low |

High |

|

FED |

Very good to excellent |

Very good |

Good to excellent |

Excellent |

Medium |

Medium |

High |

|

Plasma |

Good to very good |

Very good |

Good to very good |

Very good |

High |

High |

V. High |

a These are, of course, somewhat subjective ratings, but should give a good idea of the relative strengths and weaknesses of each type.

As mentioned at the start of this topic, the cathode-ray tube, or CRT, display has been far and away the most successful single technology in history, at least to this time. The CRT offers very good image quality, great flexibility, and is available in a very wide range of sizes and types, each geared to specific applications. In almost every market in which the CRT competes, it has been the best answer in terms of its cost vs. performance – but this has come through either having no viable competition, as was the case in the early history of electronic displays, or later through retaining a significant cost advantage over any other viable type. If cost is ignored, the CRT becomes far less attractive. It is large, in terms of the overall package required for a given screen size, it is heavy, and it is relatively fragile. Today, a number of the alternative types, most of which fall into the “flat-panel display” (FPD) category, can provide equivalent or superior image quality performance, reliability, and flexibility, in a much lighter and physically smaller overall package. And as the cost penalty associated with these types continues to decline, they are taking more and more market share away from the CRT. It is far too soon to consider the CRT display as obsolete; hundreds of millions are still produced each year, and as of this writing (in 2002), that annual volume is still expected to increase through most if not all of the foreseeable future. Still, there is no doubt that eventually the CRT will be completely replaced by a combination of several of the “flat-panel” types.

Distinguishing among these types by the applications to which they are best suited is primarily, at this point, a matter of screen size (Figure 4-19). The two most popular broad categories of FPDs at the present time are the liquid-crystal display (LCD) and the various plasma types. LCDs for now remain dominant in applications requiring small-to-medium size screens; those needing diagonal sizes of perhaps 1 cm to 0.75 m. So far, LCDs over approximately 50-55 cm (20-21 inches) in diagonal size are considered “very large,” and are very low-volume, high-cost products aimed as some very specific applications. Conversely, plasma screens require physical structures and operating voltages which do not lend them-selves readily to being scaled down to small displays. Plasma is today the dominant FPD type in roughly the 0.5 to 1.5-2.0 m (diagonal) range. Displays above this size are almost always of the projection type, based on any of a number of basic technologies.

Figure 4-19 Practical size ranges (diagonal) of various display technologies. The upper size limit of many of the flat-panel technologies is not yet clear, as new advances continue to push the potential of the LCD, OLED and FED types. “Microdisplays” are, of course, not a separate technology per se, but rather an adaptation of any of a number of technologies to very small (3 cm or smaller) displays.

The newer FPDs, at least in terms of their commercialization and acceptance into the market, are the organic-LED (OLED) and field-emission (FED) types. These will be rapidly gaining in market share over the next few years, but are currently expected to enter the market at the low end (in small, portable display applications), and then grow upwards in size and capability. As such, they are direct competitors to the LCD only, and specifically the smaller, low-power types such as the STN-LCDs commonly seen today in portable equipment. These newer technologies are distinguishing themselves on image quality issues, such as viewing angle and color, with the LCD’s main advantage over them coming in the area of power (at least for the purely reflective types).