27.7.

Steering Components

27.7.1.

Steering Column

The steering column is primarily a supported shaft that connects the driver’s steering wheel to the gear unit. The steering column in the modern automobile is a complex mechanism. It is designed to collapse in a collision to protect the driver. In some installations it may be tilted and telescoped to place it at a convenient angle for the driver. It also contains steering gear and transmission locks. A panic stop through braking slows the vehicle at the maximum deceleration rate of 6 m / s and the required time to stop the vehicle from 32 kmph is 1.5 seconds. This panic stop tends to lift the passengers and driver from their seats and carry them into front of the compartment, unless they are secured with seat and shoulder belts. In a head-on collision, two collisions actually occur. The first is the vehicle’s collision with the object and the second is the occupants’ collision with the instrument panel and windshield in the front of the passenger compartment. The modern passenger car front end is designed to crush approximately 15.5 mm / km on collision, in order to decelerate the passenger compartment in the longest possible time period and, thereby reduce the severity of the secondary collision of the occupants. In a head-on collision, the driver is thrown against the steering wheel about one one-hundredth of a second after the front of the vehicle begins to crush. The old-style steering column is often pushed into the driver as the front of the vehicle is collapsed. Impact absorbing steering columns have been designed to collapse their lower section rather than pushed back. The upper end of these columns is also designed to absorb the secondary impact of the driver hitting the wheel by collapsing.

Construction.

The steering column must be strong and rigid enough to support normal driving loads and yet collapse at a controllable rate when collision loads are applied. The steering column consists of three major components, a steering shaft, a shift tube, and a column or mast jacket. The steering shaft connects the steering wheel to the steering gear unit through a universal joint type coupling. In some of the old steering gears, an extension of the steering gear worm shaft forms the steering shaft. A shift tube surrounds the steering shaft, the upper end of which is connected to the shift selector lever and the lower end has a bell crank that attaches to the shift linkages. The shift tube is enclosed in the mast jacket, which provides the support to shaft bearings, the mounting brackets, and column trim. The mast jacket is held in the vehicle by a floor plate retainer at the lower end and a break-away bracket just below the instrument panel. Suitable attachments are added to prevent any upward movement and to allow the column to move downward in a collision.

The earlier impact absorbing mast jackets have a section with diamond perforation cutouts which bulge outwards in a collision, allowing the jacket to shorten. The second generation impact absorbing mast jacket is made of two tubes. The upper tube just slips over the lower tube and steel balls in an injected plastic sleeve are wedged between the two tubes, making a secure mast jacket. The steel balls extrude grooves in the tubes as they are forced together during collision, and thus gradually slow the secondary driver’s impact at a controlled rate.

An adapter is used at each end of the mast jacket to serve as either a bearing or bearing support for the shift tube and steering shaft. The shift tube is made of two or three short pieces of tubing, one fitted inside the other, and rectangular and round holes are made in the tubes at the joints. These joints are then injected with plastic to hold them in position and in a collision the plastic inserts in the hole are sheared, allowing the shift tubes to telescope together. The shift tube in all steering columns provides rigidity, even though the vehicle may be equipped with a floor mounted gear shift lever.

The steering shaft has two sections. The upper section is a solid rod that fits into a hollow lower section. Two external flats on the upper section mate with internal flats in the lower section to transmit steering effort. Plastic inserts are injected into the holes in the lower section and around grooves in the upper section just under the holes, which lock the two steering shafts together. A collision shears the plastic due to which the steering shaft becomes telescope and shorter.

In addition to upper steering shaft bearing and steering wheel, there are number of items such as the transmission selector lever, turn signal switch, emergency flasher switch, ignition switch, shift and steering lock mechanism, speed control, steering wheel tilt mechanism, and a means to allow the wheel to travel in and out, which are installed on the upper end of the steering column depending upon the automobile model.

The transmission selector lever is connected to the shift tube, which has a gate that restricts shifter movement between neutral and drive unless the shift lever is shifted preventing accidental movement into a gear. The selector lever fits through a housing or hub, which trims the upper end of the steering column.

The turn signal switch is located directly under the steering wheel. After a turn is completed, a protrusion on the bottom of the steering wheel cancels the signal. When the horn is actuated, contact is made between the slip ring, placed on the steering wheel, and the steering coulumn which completes the horn circuit to ground and blows the horn. Tilting and telescope travelling steering columns have a much more complex upper steering column end (Fig. 27.51). The upper end of the steering shaft is fitted with a yoke, which forms the part of the universal joint. A short upper shaft is also fitted with a yoke. The universal joint is incorporated with a plastic sphere that fits between the two yokes. The yoke and upper shaft are enclosed in support housing and end cover. The upper shaft support swivels up and down in the housing, locking in a number of positions. The position locking shoes are released with a lever to tilt the steering wheel to a new position. The hollow upper shaft slides into the hollow upper yoke to allow the steering wheel to travel in and out. It is held in position with a cam-type wedge locking into a keyway in the yoke.

Service.

A normal steering column service involves work on the upper end of the steering column, Which can be done with the steering column remaining in the car. Any work on the steering column requires removal of steering wheel. The upper trim, often a horn button, bar or ring must be removed to separate steering wheel. Removal of upper trim exposes the steering wheel nut. The steering wheel requires pulling from a set of splines on the steering shaft, after the

Fig. 27.51. A typical tilt and travel

nut is removed, for which, the pullers are used. Removal of steering wheel exposes the turn signal switch mechanism. The position of the master spline should be noted to reinstall the steering wheel. Repair work necessary on the parts can be carried out using proper tool and following applicable shop manual.

27.7.2.

Steering Gears

The steering gearbox provides the driver with a leverage to enable him to exert a large force at the road wheel with a minimum effort, and to control the direction of the wheel. Turning effort on the steering wheel is multiplied through the steering gears to turn the front wheels, even when the vehicle is at rest. Therefore, the steering gearbox has two main functions. It produces a gear reduction between the input steering wheel and the output drop arm (Pitman arm) and it redirects the input to output axis of rotation through a right angle.

The overall angular gear ratio between the steering wheel and the road wheel varies from about 12:1 to 30:1, depending on the load on the road wheels and the type of steering. The lower ratio is for the light small vehicles and the higher ratio for heavy vehicles. As the ratio is lowered, a more number of turns are required to move the wheels from lock to lock making it difficult for a rapid change in vehicle direction.

Normally, the steering road wheel stub axles must be able to twist through a maximum steering angle of 40 degrees either side of straight ahead position. Therefore, lock to lock drop arm angular displacement amounts to 80 degrees and with a 12:1 and 30:1 gear reduction the number of turns of the steering wheel would be as follows:

Lock to lock steering = 80 x 12/360 = 2.66 revolutions the wheel turns for 12:1 reduction.

Lock to lock steering = 80 x 30/360 = 6.66 revolutions the wheel turns for 30:1 reduction.

These results show that the while the 12:1 reduction requires the steering wheel to be rotated through 1:33 turns from the straight ahead position, the 30:1 reduction requires 3.33 turns which is more than twice of the former angular displacement. Thus with the 12:1 gear reduction, the steering may be heavy but can be turned from the straight ahead position to full lock and back again relatively quickly. However the 30:1 reduction provides a light steering wheel but the vehicle is forced to corner much slower if the driver is able to complete the manoeuvre safely.

Over the years, several types of steering gearbox have been used, these include :

(i) Screw and nut.

(ii) Rack and pinion. (Hi) Cam and peg.

(iv) Worm and roller.

(v) Worm and sector.

(vi) Re-circulating ball.

27.7.3.

Screw and Nut Steering Gear Mechanism

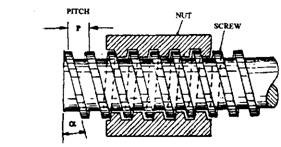

The screw and nut type mechanism is the basic form for all the other types of steering gear box mechanisms (Fig. 27.52). This mechanism increases both the force and movement ratios. A small input effort applied to the end of a perpendicular lever fixed

Fig. 27.52. Screw and nut steering gear mechanism.

to the screw can move a much larger load axially along the screw, provided the nut is held against rotating.

If the screw is prevented from moving longitudinally, but revolves once within its nut, then the nut advances or retracts a distance equal to the axial length of one complete spiral groove loop. This distance is termed as the thread pitch or lead (p). The inclination of the spiral thread to the perpendicular of the screw axis is known as the helix angle (a). As the helix angle decreases the nut displaces greater load in an axial direction.

The engaged external and internal spiral threads of the screw and nut mechanism may be considered as a pair of infinitely long inclined planes. When the screw is rotated keeping the nut stationary, the inclined plane of the screw slides relative to that of the nut. Due to comparatively large surface areas in contact between the male and female threads and difficulty of maintaining an adequate supply of lubricant between the rubbing faces, this mechanism provides a relatively high friction, which causes low mechanical efficiency and high rate of wear. This friction can considerably be reduced by introducing a series of balls (Fig. 27.53) which roll between the inclined planes as the screw is rotated relatively to the nut.

The overall gear ratio in a screw and nut steering gearbox is achieved in two stages. In the first stage the nut moves along the pitch length for every one complete revolution of the steering wheel. In the second stage the linear movement of the nut is converted back to an angular one through an integral rocker lever and shaft.

The forward efficiency of a steering gearbox is denned as the ratio of the output work produced at the drop arm to move a given load to that of the input work performed at the steering wheel to achieve this movement,

Fig. 27.53. Screw and nut re-circulating ball gear mechanism.

![]()

Fig. 27.54. Efficiency curves for a screw and nut re-circulating ball steering gear.

Conversely, the reverse efficiency of a steering gearbox is defined as the ratio of the output work produced at the steering wheel rim causing it to rotate against a resisting force to that of the input work performed on the drop arm to produce this movement,

![]()

The efficiency of a screw and nut mechanism varies with the helix angle (Fig. 27.54) and is maximum in the helix angle region of 40—50 degrees for both forward and reverse directions. It falls to zero at the two extremes of 0 and 90 degrees helix angle. The plots of both forward and reverse efficiency curves for a screw and nut device look similar but appear to be out of phase by an amount known as the friction factor.

If a helix angle is selected (say 40°) for the maximum forward efficiency at point A and also for a very high reverse efficiency at point A’, then every twitch of the road wheels caused by any irregularities on the road surface is transmitted to the steering wheel. Therefore, a smaller helix angle in chosen (say 30°), which produces only a slight reduction in the forward efficiency at B but a relatively much larger reduced reverse efficiency at B’ is obtained. Consequently, this absorbs and damps the majority of very small vibrations generated by the tyres rolling over the road contour.

A typical value for the helix angle is about 30 degrees, which produces forward and reverse efficiencies of about 55% and 30% respectively without recirculating balls. By introducing the balls between the screw and nut, the forward and reverse efficiencies become approximately 80% and 60% respectively.

27.7.4. Rack and Pinion Steering Gear Mechanism

The rack-and-pinion gear mechanism transfers the circular input motion of the pinion into a linear rack output movement so that side-to-side travel of the rack is transferred through the tie-rods to the tie-rod steering arms and the stub-axles (Fig. 27.55). To transfer the motion from the pinion to the rack, the pinion teeth mesh with rack teeth along the rack axis for movement in either direction. The circular pitch of the pinion should be equal to the linear pitch of the rack for correct mesh.

Fig. 27.55. Principle of rack and pinion steering.

Let, R = steering-wheel radius

r = pinion pitch circle radius

t = number of pinion teeth p – linear or circular pitch E = input steering-wheel effort and W = output rack load.

The movement ratios of rack and pinion steering gears for manual steering, depend largely on the weight of the vehicle, and range from 12:1 for small cars up to 22:1 for heavier vehicles.

The rack-and-pinion steering-box (Fig. 27.56) uses a pinion-gear connected to the steering-wheel through a coupling and universal joints. The pinion gear is supported by two ball-race bearings. The rack is a circular-sectioned shaft with teeth cut along one face and is positioned perpendicular to the pinion. The rack is aligned to mesh with the pinion and slides in its tubular

Fig. 27.56. Rack-and-pinion steering gear.

housing between two bearings. A plain bush bearing is placed at one end of the housing, and an adjustable half bearing support yoke opposite the pinion gear is obtained at the other end of the casing. The half-bearing yoke pushes the rack teeth into mesh with the pinion teeth and also controls the amount of back-lash between the rack and pinion teeth. Since the rack is a gear of infinite diameter, its pitch circle is a straight line. Both gear-teeth profiles are of the involute form. The side profile of the pinion teeth is curved, and the sides of the rack teeth is straight and inclined (Fig. 27.55).

In case of straight-cut rack-and-pinion teeth only one pair of teeth mesh and contact their whole width at any moment. Consequently, the tooth-profile contact point always moves from one side to other of the pitch-line of both the rack and the pinion teeth. Uneven movement of the rack occurs as the steering load is transferred from one pair of teeth to the next. With helical-cut rack-and-pinion teeth, more than one pair of teeth comes into contact at any instant. Also the teeth engage progressively and there is some contact on the pitch-line at all times. As a result, the helical pinion teeth take greater loads, engage smoothly and operate quietly.

If the pinion axis is tilted to the perpendicular to the rack travel (Fig. 27.56C), the effective pinion pitch radius increases for a given rack movement so that the use of fewer and stronger pinion teeth is possible, and a larger gear ratio reductions can be employed for a given rack travel. Both the helix angle of the teeth and the inclination of the pinion axis to the perpendicular introduce a sliding action between meshing teeth, due to which friction is increased. The damping effect of this internally generated friction prevents transmission of road-wheel shock impulses to the steering wheel.

The pinion ball-race bearings must be provided with a specified axial pre-load during assembly. This initial degree of compression eliminates any end-float or relative free movement in the bearings when subjected to operating conditions. To obtain the correct meshing of the rack-and-pinion teeth, the bearing support yoke is moved towards or away from the rack. The shims of selected thickness are inserted between the housing and the yoke cover plate to adjust the relative position of the bearing support yoke to the pinion housing.

Example 27.4. A rack-and-pinion steering has a pinion of 16 mm pitch-circle diameter. What effort must be applied on the 320 mm diameter steering-wheel to overcome a resistance of500 N experienced transversely on the track ?

Example 27.5. A rack-and-pinion steering gear has a 5 tooth pinion of 10 mm pitch. If an effort of 15 N is applied by each on the 350 mm diameter steering-wheel, (a) determine the movement ratio, and (b) the force transmitted to the tie-rods.

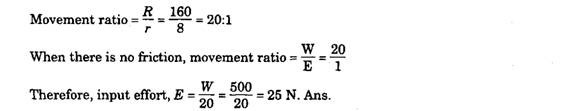

Fig. 27.57. Cam and peg steering type gear box.

27.7.5.

Cam and Peg Steering Gearbox

This type of steering box incorporates, in place of the conventional screw, a cylindrical shaft, supported between two angular contact ball bearings (Fig. 27.57). The shaft carries a deep spiral groove, usually with a variable pitch, on its surface between the bearings. The groove has a tapered profile, which narrows towards the bottom. An integral rocker arm and shaft is placed half-way along the cam. At the free end of the rocker arm a conical peg is fitted which engages the groove. When the steering wheel and shaft rotate the camshaft, one side of the spiral groove screws the peg axially forward or backward, depending upon the direction of turning of the cam. This forces the rocker arm to pivot about its shaft axis and as a result a similar angular motion is transferred to the drop arm, which is attached to the shaft’s outer end.

The spiral pitch is provided with the minimum pitch in the mid-position to increase the mechanical advantage of the cam and peg device. The progressively increased pitch towards either end of the cam provides more direct steering response using increased steering effort as the steering approaches full lock. Preload of the ball races supporting the cam is adjusted by changing the thickness of shim between the end plate and housing. Spring loaded oil seals are used at both the drop arm end of the rocker shaft as well as at the input end of the camshaft.

In low efficiency cam and peg steering boxes the peg is pressed directly into a hole drilled in the rocker arm. Top improve efficiency the peg is supported with needle rollers assembled inside an enlarged bore in the rocker arm. In the high efficiency heavy duty arrangement the peg is supported with opposing taper roller bearings mounted directly onto the rocker arm, which is shaped to form the inner tracks of the bearings. Cam and peg mechanism have average forward and reverse efficiencies of 50% and 30% respectively for pegs that are fixed in the rocker arm, and of 75% and 50% respectively for needle mounted pegs.

A rocker shaft end play adjustment screw is made to contact a ground portion of the rocker shaft upper face to obtain the correct depth of peg to cam groove engagement. The rocker shaft rotates in a bronze plain bearing at the drop arm end and directly against the bearing bore at the cam end. To increase the efficiency further by 3 – 5% the plain bush rocker shaft bearing can be replaced by needle bearings.

Fig. 27.58. Worm and roller type steering gear box.

27.7.6.

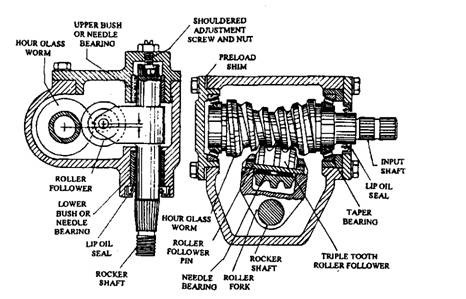

Worm and Roller Steering Gearbox

This steering gear uses an hourglass-shaped worn (the cam) mounted between opposing taper roller bearings. The outer race of the bearings is located in the end plate flange and in a supporting sleeve at the input end of the worm shaft (Fig. 27.58). Shims, incorporated between the end plates and housing, are used for adjusting the taper roller bearing preload and for centralizing the worm relative to the rocker shaft.

A roller follower having two or three teeth engages with the worm teeth and is carried on two sets of needle rollers supported on a short steel pin, which is located between the fork arm an integral part of the rocker shaft. To reduce frictional losses, the needle rollers are replaced by ball races, which support radial loads and also end thrust. The rocker shaft is supported on two plain bushes located in the steering box and other in the top cover plate. A shouldered screw located in a machined mortise to T slot at one end of the rocker shaft, absorbs end thrust in both directions on the rocker shaft.

In order to adjust the depth of mesh of the worm and roller (Fig. 27.58), the steering wheel is moved to the mid-position of the number of turns of the steering wheel from lock to lock. The end thrust shouldered screw is screwed until all free movement is taken up and then the lock nut is tightened to reduce offset distance. The cam is centralised relative to the rocker shaft roller so that there is an equal amount of backlash between the roller and worm at a point half a turn of the steering wheel at either side of the mid-position. Any adjustment necessary is carried out by removing the shims from one end plate and adding the same to the existing shims at the other.

The forward and reverse efficiencies of the worm and roller gear are respectively 73% and 48%, which are slightly lower than the cam and peg type of gear. These efficiencies to some extent depend upon the design. To obtain higher efficiencies a needle or taper roller bearing can be used between the rocker shaft and housing instead of the usual plain bush type of bearing.

27.7.7.

Worm and Sector Steering Gearbox

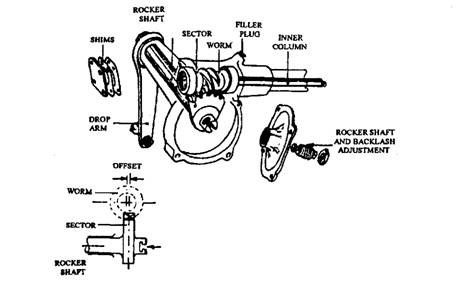

This type of gear box is the outcome of advancement of the old worm and wheel type designs. A case-hardened steel worm and sector are located by bearings in a malleable iron or light alloy casing. Figure 27.59 represents the worn and sector steering mechanism. The worm is connected to the inner column and the sector forms a part of the rocker shaft in the steering gear box.

Fig. 27.59. Worm and sector steering box.

Similar to many other boxes, the layout also can have adjustments, which include; (i) End-float of inner column is adjusted using shim.

(ii) End-float of rocker shaft is adjusted using shim or screw.

(Hi) Backlash between gears is adjusted by moving the gears.

Since maximum wear occurs in the straight ahead position of the box, the gear is normally provided with a larger backlash in the lock positions. This reduces the risk of seizure at full lock when the box is adjusted to compensate for wear. It is essential to reduce end float and backlash to a minimum. Steering box lubrication is provided by filling the box to the level of the plug with normal gear oil.

27.7.8.

Re-circulating Ball Nut and Rocker Lever Steering Gearbox

This design is an improvement of the simple screw and nut gear box by replacing the male and female screw thread by semicircular spiral grooves formed onto the input shaft and inside the bore of the half nut. A ring of steel balls are loaded between the internal and external grooves within the nut assembly (Fig. 27.60). The portion of the shaft with the spiral groove is known as the worm, which has a single start left hand or right hand spiral for right hand or left hand drive steering respectively.

Fig. 27.60. Re-circulating ball nut and rocker lever steering type gearbox.

The worm shaft is supported between two sets of ball races installed at either end normally in an aluminium housing. The bearing preload is adjusted by steel shims sandwiched between the detachable plate mounted at the input end of the shaft. A spring loaded lip seal contacts the smooth surface portion of the worm shaft and is situated on the inside of the end plate. A half nut is assembled to the worn with a ditachable semicircular transfer tube, secured to the nut by a retainer and two bolts. The steel balls are fitted in the passage formed by the grooves and transfer tube and are free to move during rotation of the worm shaft.

The half nut carries an extended tower of a conical seat and a spigot pin. After assembly, the conical seat engages with the bevel forks of the rocker lever, whereas a roller on the nut spigot engages a guide slot formed parallel to the worm axis in the top cover plate. During rotation of the worm shaft the spigot roller, engaged in its elongated slot, prevents the nut from turning. Movement of the nut along the worm provides axial displacement of the spigot roller in its slot.

A spring-loaded plunger presses the rocker lever bevel forks against the conical seat of the half nut and controls the end float of the rocker lever shaft. The rocker lever shaft is supported directly in the bore of the housing material at the worm end and by a bronze bush in the housing at the drop arm end. An oil seal, installed just inside the bore entrance of the rocker shaft, retains the lubricant within the steering box housing. The attachment of the steering shaft is provided by the parallel serrations in the worm shaft. The rocker shaft is jointed to the drop arm by a serrated taper shank.

This type of re-circulating ball and rocker lever gear has forward and reverse efficiencies of approximately 80% and 60% respectively.

27.7.9.

Re-circulating Ball Rack and Sector Steering Gearbox

To reduce friction and improve efficiency, in place of the conventional screw and nut threads the semicircular spiral grooves (Fig. 27.61) are machined externally around and along the

Fig. 27.61. Re-circulating ball rack and sector steering gearbox.

cylindrical worm shaft. A similar groove is also machined internally through the bore of the nut. A series of steel balls are loaded between the two sets of matching semicircular spiral grooves to engage the worm and nut.

When the steering wheel and worm rotates, the balls roll in the grooves against the nut in two separate ball circuits, causing the nut to move along the worm. Each ball enters a ball return guide after completing one loop around the worm. The guide deflects the balls away from the grooved passages to cause their movement diagonally across the back of the nut. The balls are redirected again into the grooved passages on the other side of the nut.

One outer face of the rectangular nut is machined to form a gear rack teeth, which meshes with a toothed sector shaft. Motion from the nut is transferred to the drop arm through the toothed sector shaft so that the linear movement of the nut is converted back to a rotary motion by the sector and shaft.

In this type of steering gear, the rack and sector allows the drop arm to have a larger angular movement than most other types of gear mechanisms. Due to the additional second stage gear reduction of rack and sector, the overall forward and reverse efficiencies are slightly lower than other re-circulating ball mechanisms, the typical values being 70% and 45% respectively.

Fig. 27.62. Relationship of the tyre grip on various road surfaces and the torque reaction on the steering wheel.