25.7.

Rod and Fork Gear Selectors

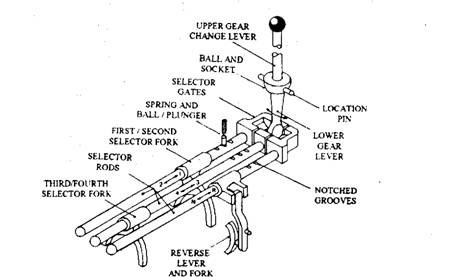

A gear-selector mechanism permits the driver to select and engage individual gear ratios. The selector mechanism consists of three guiding selector rods supported at their ends either in the actual gearbox housing or in the selector cover housing. Selector forks slide with or over these rods and fit over saddle-like grooves machined on the outer sliding-dog clutch hub. When a selector fork is pushed towards one of the constant-mesh gearwheels, it moves the particular dog-clutch hub over the exposed ring of dog teeth on the gearwheel. Once the hub and gearwheel dog teeth are meshed, the lay-shaft cluster gear is coupled to the main output shaft, so that the power-flow path through the gearbox is completed. For the neutral gear, the selector forks are moved to place the outer dog-clutch hubs directly over the inner hubs. This causes each gearwheel on the main shaft to revolve independently (Fig. 25.14) about it.

Gear-change Lever Action.

The gear-change lever is a forged steel rod, the upper end of which has a control knob screwed on to it and the lower end is spherical with flats machined on each side. A swivel ball, located at about one fifth of the length of the lever from its lower end, provides a pivot point for the lever gear-selection action (Fig. 25.14). The lower spherical end fits in the selector-rod gate in such a way that the machined flats lying parallel to the rods. The swivel-ball portion of the lever sits in a socket machined in the lever cover casting. A spring-loaded dust-cover and a spherical washer, which holds the lever ball in position (Fig. 25.15), are fitted over the lever swivel ball.

To select and engage a gear ratio, the lever is tilted at right angles to the rods. This causes the spherical lever end to sweep across the three selector gates so that the flats align with the selected rod corresponding to the desired gearwheel. The lever knob is then pushed parallel to the selector rods and in a direction, which shifts through the selector fork the dog-clutch outer hub over the dog teeth formed on the side of the selected gearwheel.

Spring-loaded Ball or Plunger and Selector-rod Grooves.

The selector rods are located and held in their selected position by spring-loaded balls or plungers and grooves (notches). The spring load forces the balls into their respective grooves when they align (Fig. 25.15). Each of the two forward-gear selector rods has three grooves and the reverse selector rod has two grooves. When the selector rods and their forks are shifted one way or the other, these grooves eventually align with the spring loaded balls or plungers when a gear position is reached. On the forward-gear selector rods the central groove corresponds to the neutral position and the grooves on either side corresponds to engaged position for first or second or third or fourth gear. The reverse selector has only a neutral and a reverse position.

Fig. 25.14. Rod-and-fork gear-selector arrangement.

Fig. 25.15. Three-rod gear-selector mechanism with plunger-and-pin interlocking device.