Starting Systems

The function of the electric motor is to convert electrical energy into mechanical energy, with the greatest possible efficiency. On an automobile, electric motors are used to start the engine and to drive various mechanisms. As cars become more and more highly specified the number of motors used continues to increase. Some prestige vehicles now carry close to 100 motors. The majority of these are simple permanent magnet variety, but for some applications more sophisticated stepper motors are used, often controlled by a microprocessor.

For starting, an engine is required to be turned-over (or cranked) at a speed sufficient to cause reasonable turbulence of the incoming air-fuel mixture so that combustion is possible. In addition, the engine’s flywheel must be given sufficient momentum to keep it rotating for the first couple of firing strokes until the engine develops sufficient power to run unassisted. Typically, a petrol engine requires a minimum cranking speed in the region of 50-100 rpm to ensure starting in cold weather, whereas a diesel engine requires at least 100 rpm. The luxury cars were fitted with electric self-starters as early as 1912, and they were a standard fitment on most prestige cars from the 1920s onward. By the 1960s, even the cheapest car was fitted with an electric starter.

All practical DC motors operate on the principle of interaction between two magnetic fields; one field is produced by the stator and the other is produced by current flowing in the rotor winding. The chapter presents various types of DC motors used in both light vehicle and heavy vehicle starting systems, the principle of operation, their construction, drives, testing, maintenance etc.

15.1.

Requirements of the Starting System

An internal combustion engine requires (i) a combustible mixture, (ii) compression stroke, (Hi) a form of ignition, and (iv) the minimum initial starting speed (about 100 rpm) in order to start and continue running. To meet the first three of these requirements the minimum starting speed must be attained. This is where the electric starter comes in. The attainment of this minimum speed is again dependent on a number of factors, such as ;

(i) The rated voltage of the starting system.

(ii) The lowest possible temperature at which the engine can still be started. This is known as the starting limit temperature.

(Hi) The torque required to crank the engine at its starting limit temperature (including the initial stalled torque).

(iv) The battery characteristics.

(v) The voltage drop between the battery and the starter.

(ui) The starter to ring gear ratio.

(uii) The characteristics of the starter.

(viii) The minimum cranking speed of the engine at the starting limit temperature.

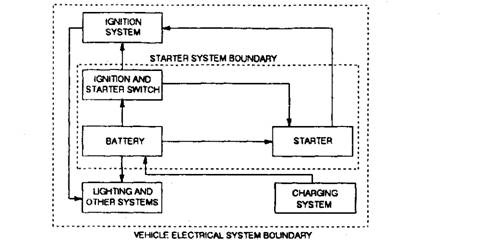

It can be clearly seen in Fig. 15.1 that it is not possible to look at the starter as an isolated component within the vehicle electrical system. The battery in particular is of prime importance for consideration.

Fig. 15.1. Starting system within the complete electrical system of the vehicle.

The starting limit temperature is another important factor in relation to engine starting requirements. Figure 15.2 illustrates how the starter torque decreases as temperature decreases, but the torque required in cranking the engine to its minimum speed increases. Typical starting limit temperatures are 255 K to 248 K for passenger cars and 258 K to 253 K for trucks and buses. The starter manufacturers often quote the figure as 293 K and 253 K.

Fig. 15.2. Starter torque and engine cranking torque.

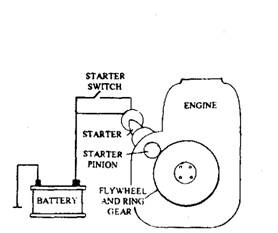

Fig. 15.3. Starting system general layout.

The starting system (Fig. 15.3) of any vehicle must fulfil the following criteria in addition to the eight factors listed above for its efficient functioning.

(i) Long service life and low maintenance needs.

(ii) Continuous readiness to operate.

(Hi) Robustness to withstand starting forces, vibration, corrosion and temperature cycles. (iv) The lowest possible size and weight.

First it is important to find out the minimum cranking speed for the particular engine and this varies considerably with the design and type of engine. Some typical values of speeds for the temperature of 253 K are:

(i) Reciprocating spark ignition engine 60 to 90 rpm.

(ii) Rotary spark ignition engine 150 to 180 rpm. (Hi) Diesel engines with glow plugs 60 to 140 rpm. (iv) Diesel engines without glow plugs 100 to 200 rpm.

It has been already pointed out earlier that the rated voltage of the system for passenger cars is 12 V and for trucks and buses are generally 24 V. The system with 24 V requires half the current needed with a 12 V system to produce the same power. Also it reduces the voltage drop considerably in the wiring as the length of wires used on commercial vehicles is much greater than in passenger cars.

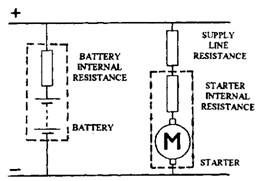

To determine the rated output of a starter motor on a test bench, a battery of maximum capacity for the starter having a 20% drop in capacity at 253 K is connected to the starter with a cable of lmQ resistance. These criteria enable the starter to operate even under the most adverse conditions. The output of the starter can now be measured under typical operating conditions. The rated power of the motor corresponds to the power drawn from the battery less copper losses (due to the resistance of the circuit), iron losses (due to eddy currents being induced in the iron parts of the motor) and friction losses. An equivalent circuit for a starter and battery is represented in Fig. 15.4. This indicates how the starter

Fig. 15.4. Equivalent circuit for a starter system.

output is very much dependent on line resistance and battery internal resistance. The lower the values of these two resistances, the higher is the output from the starter.

There are two other factors to be considered when designing a starting system. The location of the starter on the engine is normally pre-fixed but the position of the battery must be determined. If the battery is close to the starter the cables are shorter. A longer run needs cables with a greater cross section to have a low resistance. Depending on the type of use of the vehicle, such as running on off road conditions, special sealing of the starter against the ingress of contaminants may be necessary.